-

Legacy Member

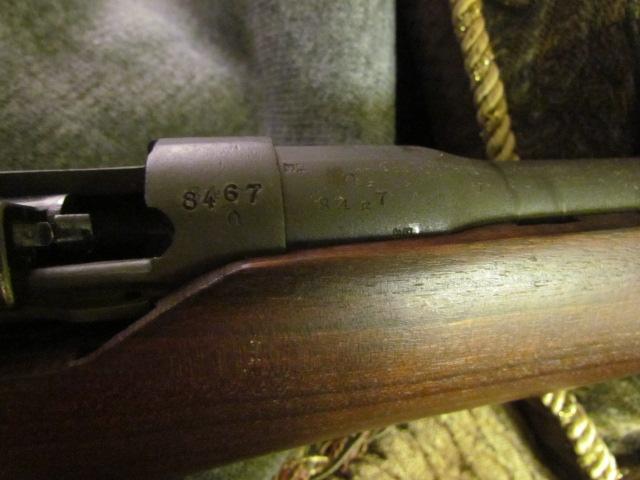

Nice follow up photo of the charger bridge with no JJinc import stamp. The dual finish does look like that in a previous posting of a JJinc import.https://www.milsurps.com/showthread.php?t=38243

Again, lovley rifle. Thanks for the nice photos.

-

-

02-21-2013 07:11 PM

# ADS

Friends and Sponsors

-

-

-

-

Legacy Member

I have a 21 Lithgow MkIII* that was rebarreled by Lithgow in (I believe) '45 that has very similar (although lighter) colour of Parkerizing applied to everything. Can anyone comment if that was a normal Lithgow practice late in the war? Thanks for all the photos NortonJPS.

MkIII* that was rebarreled by Lithgow in (I believe) '45 that has very similar (although lighter) colour of Parkerizing applied to everything. Can anyone comment if that was a normal Lithgow practice late in the war? Thanks for all the photos NortonJPS.

Ridolpho

-

-

FREE MEMBER

NO Posting or PM's Allowed

Under the sight. Thanks again for the info guys, I will get pictures of the stamping on the barrel, as soon as I get the courage to take it apart. So maybe the parkerizing was part of a restoration? Interesting.

-

FREE MEMBER

NO Posting or PM's Allowed

-

-

The Following 2 Members Say Thank You to Brian Dick For This Useful Post:

-

Legacy Member

Looks like one of the incomplete JJovino actions that someone completed with a mixture of English and Australian parts.

parts.

-

-

The rear sight had been around the block a couple of times before it found a home on this rifle. Nothing wrong with that, being a 1938 rebuild, but the finish overall would have been a fine bluing at that time as noted above. ("Rust bluing" in modern parlance- "browning" in the pre-WWII terminology.) It does seem to have had a heavy blasting before the phosphating, not sure why, it doesn't look like they were trying to hide anything.

The SSA "peddled scheme" rifles are a bit scarce, as also noted above, and have an interesting production history.

Looks good, regardless, hopefully it'll shoot as well!

-

-

FREE MEMBER

NO Posting or PM's Allowed

Great info everyone. So basically I have a SSA manufacture (peddled scheme) rifle, that has had a stock replacement, been restored and parkerized at some point. I'm actually happy that it is not some super rare Enfield, because I could not bring myself to shoot it. It looks great and I plan to take it to the range and have some fun! Thanks again everybody.

-

Legacy Member

jmoore:

"It does seem to have had a heavy blasting before the phosphating, not sure why",

Basically, you cannot get a decent phospate finish unless the work is "blasted" beforehand, and the item goes in the phospahing tank as soon as possible after the blasting stage.

The grit-blasting "activates" the surface of the steel by doing a couple of things:

1. It removes the very thin "ceramic" skin on heat-treated (especially hardened) steel.

2. The mechanical "disruption" to the otherwise smooth surface increases the effective surface area enormously.

3. The molecular micro-stesses caused by this "disruption" greatly increases the reactivity of the surface with the phosphoric acid brew.

The grey colour comes from Zinc being added during the process: If you want black, add Manganese.

Basically, you cannot get a decent phospate finish unless the work is "blasted" beforehand, and the item goes in the phosphating tank as soon as possible after the blasting stage.

When the item comes out of the bath it has a VERY active surface and will just about rust while you watch.

Thus, it is usual to rapidly immerse the item in a second bath of boiling water. This process partly "closes up" the crystal structure, but it is still porous.

Then you have to quickly douse it with a de-watering fluid before applying a light oil.

Ultimately, the entire purpose of phosphating is to form a strongly-bonded skin that holds oil to prevent corrosion.

Apart from all that: A heavy "blast" will also "hide" rust pits and other "imperfections". This may or may not be a good thing.

Last edited by Bruce_in_Oz; 02-24-2013 at 02:02 AM.

-

The Following 7 Members Say Thank You to Bruce_in_Oz For This Useful Post:

PM

PM