-

Legacy Member

aye, there's more than one way to skin a cat. I'm hoping to have a rifle here soon to start trying stuff on.

-

-

04-09-2020 04:22 PM

# ADS

Friends and Sponsors

-

Legacy Member

Originally Posted by

Surpmil

There's a fairly simple and cheap option: buy a reproduction base, mill off all or most of the existing ring "cradles" and braze/screw/silver solder/TIG weld on a steel Picatinny rail.

A good first step in that process would be to find some cold rolled 1" "half oval" bar stock and braze/screw/silver solder/TIG weld that into the existing lower ring "cradles" to produce a solid flat surface that can be milled to whatever level is required.

Or simpler yet, zip-cut a couple of short chunks of 1" CR bar into some home made "half oval".

The problem with this idea is the scope height of the finished mount will be to high.

-

-

-

Advisory Panel

Originally Posted by

Bindi2

The problem with this idea is the scope height of the finished mount will be to high.

Hm, well let me see...perhaps cut the rings off entirely and attach a piece of flat bar lower down?

But just how low can one go?

“There are invisible rulers who control the destinies of millions. It is not generally realized to what extent the words and actions of our most influential public men are dictated by shrewd persons operating behind the scenes.”

Edward Bernays, 1928

Much changes, much remains the same.

-

-

Contributing Member

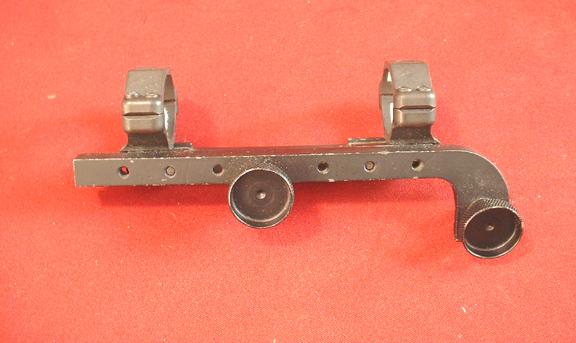

Would and IWS mount work? It has (an admittedly non pic) rail you could add some rings to

-

-

Contributing Member

Originally Posted by

Bindi2

.

Full length. will see if I can post up the photo. Don't hold your breath.

Have you seen this Demo? or are you too blue in the face from waiting?

-

-

Legacy Member

I cant get them out of picasa

Last edited by Bindi2; 04-10-2020 at 08:13 AM.

-

-

Legacy Member

Pete,

If you do find/manufacture something that will fit the repro mounts, please post the pics! That would be interesting to see.

If you consider mounts that install on the action, there are a couple different ideas that may work for you to fit larger tube scopes. Both are NDT, so no additional holes and easy to install/remove as needed. These are very sturdy mounts with no strength/longevity issues that I have found. But they are a LONG way away from Germany .

.

I have an Addley Precision mount on my partial "T" that works great. The rifle has its original cheek piece so the scope is 'right there' when I pick it up. Unfortunately it came to me with only the front scope pad, but without the rear pad in place, the mount fits perfect. The version I have is an older Weaver style no-drill mount and currently wears a 30mm Nikon PROSTAFF. It doesn't look anywhere near original to the 'knowledgeable ones' but its not bad!! The newer version of this mount has a picatinny rail.

On my regular No 4, I have an S&K mount with their Insta Mount proprietary 1" rings. I use a 'strap-on' cheek rest with an extra piece of foam to get the right height (pretty well same height as the Addley.) This doesn't really look great but it fits well and doesn't come loose or need regular tightening.

S&K also carries the same mount but with a Weaver rail so depending on the choice of rings, you could likely fit a 34mm scope and come up with something on the stock to get your eye up to level.

A couple different ideas for you..

Good luck with the project.

Kermode

-

-

Legacy Member

Hello Kermode..

The Bodge it and Leg it way would be to purchase a bracket, cut of the lower ring or mill them to suite and WIG some 34mm rings in place.. which is probably the easiest way to get a functioning bracket in 34mm.

I doubt that there is enough material to enable boring the 1" out to 34mm,, maybe to 30,, but not 34.. so i doubt that is a suitable route to follow.

The proper way to do it is to take measurements from either an original or an aftermarket bracket and from the scope, punch the keyboard into solid works and then write the program and manufacture some.. But thats time consuming..

I'll get there one way or another, and i'll post up the results here.

-

-

Legacy Member

Get some angle keeping it as low as possible to the bore mark out then cut out to suit the bracket, fabricate the brackets to mounts pieces then fix to the mount, a line the pic rail to the bore fix. Nothing to it if you have the right gear.

A little secret keep the pic rail as low as you can get it.

Last edited by Bindi2; 04-11-2020 at 06:53 AM.

-

-

Legacy Member

MJ, don't take this personally, but that's crap.

muffett.2008

-

The Following 2 Members Say Thank You to MJ1 For This Useful Post:

PM

PM