Patrick

I'm not lathered 'yet' Patrick, I will be by the time I get done cutting the grass today though.

I also respect chuckindenver's posting, the difference being because I worked in maintenance and repair fields all my life I think we could and should teach the people in these forums on what to check for and how to fix it.

There are two types of people in these forums, mechanically inclined and people who take their firearms to gunsmiths. And these people can make up their own minds on what they are going to do.

One of the reasons I supplied so many Enfield manuals to these forums was for the members to read the inspection requirements and specification and be able to inspect and repair the Enfields.

None of my milsurps have ever been to a gunsmith and I would be willing to bet over 75% of all milsurp owners never take their rifles to a gunsmith. We can teach the other 25% what to look for and how to fix their problems.

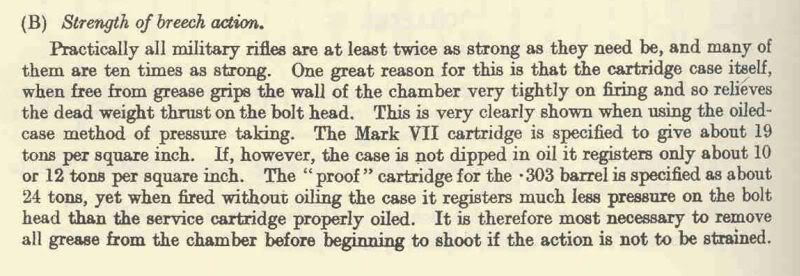

Lets not forget what the Textbook of Small Arms stated about the strength of military rifles.

The Britishmilitary to this day still proof checks their small arms using oiled proof pressure test cartridges to put maximum pressure and strain on the action and bolt.

If your milsurp was going to blow up, it would have done so long before you got it in your hands on it. You still need to visually inspect your rifles BUT short of re-proof testing, magnafluxing and possibly other tests your eyes and brain will tell you a great deal about your rifle.

All the information in the world is written in books and all you have to do is read.

Headspace/head gap clearance on the Enfield Riflecan be checked with a empty unfired case and a tool as simple as a feeler gauge.

On the 7.62 NATO you could have with military cases as much as .012 head gap clearance checking with a field gauge. (Less is better)

With commercial .308 cases you would want less than .010 for field max and between .006 and .002 would be much better.

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

Register To Reply

Register To Reply