Turner Saddlery, Inc.

Well it happened again, called ITW Waterbury Buckle back in early February to place an order for M1907 Sling Hooks/Frogs, and discovered they had split and reorganized, discontinuing the hardware I had been buying for over 20 years. Not only did they discontinue the part, they scrapped the dies. Back in 1992, Waterbury bought out Brookside Manufacturing Corp. who was a military hardware contractor, and my first supplier for the hooks. Prior to the buyout, I along with another company contracted Brookside to make new dies since there original WWII dies were worn out.

Sad thing is, ITW Waterbury Buckle was one of the only manufacturers left that were producing the majority of older metal hardware for slings, such as the M1923 Sling and the M1series of web slings. This includes the cam buckle, spring clip w/"D" ring for the rear swivel, and "N" buckle. Hope there is another manufacturer who produces these because it will hurt the web market, and I would hate to find out how much new dies for these parts would cost. I was told they had made changes and were geared more to the Clash hooks for the newer web slings. They scrapped a lot of dies and tooling, and moved Waterbury Buckle from Waterbury, CT to Broadview, IL. ITW Plastiglide is now located in their old plant in Waterbury, CT.

This is the second time over the past 25 years that this has happened. I lost another set of dies that was designed to punch a very distinctive brass hook used during WWI and was also appropriate for the M1887 Sling. Same story, company went out of business and dies were scraped before I found out, no notification on their part.

We have just had another set of punch and forming dies made. Fortunately a relative owns a tool & die shop locally and just completed the dies last week and after twice losing dies, I will keep a tight rein on these since they are in house. At the moment all our hardware will be made right here in Alabama except for our MILSPEC 13 gauge brass rivets which are made in the North East on our dies. We send the rivet dies out with the order and have them returned when the order is completed.

The hook dies were not cheap, but they are correct and the hooks/frogs, will have a smooth edge on the face of the hook, where as the progressive dies that Waterbury was using (blanked two hooks at a time to reduce waste), double blanked the hook, leaving a burred edge on half of the face of the hook. Our dies are progressive, but a little more handling per hook during the forming process.

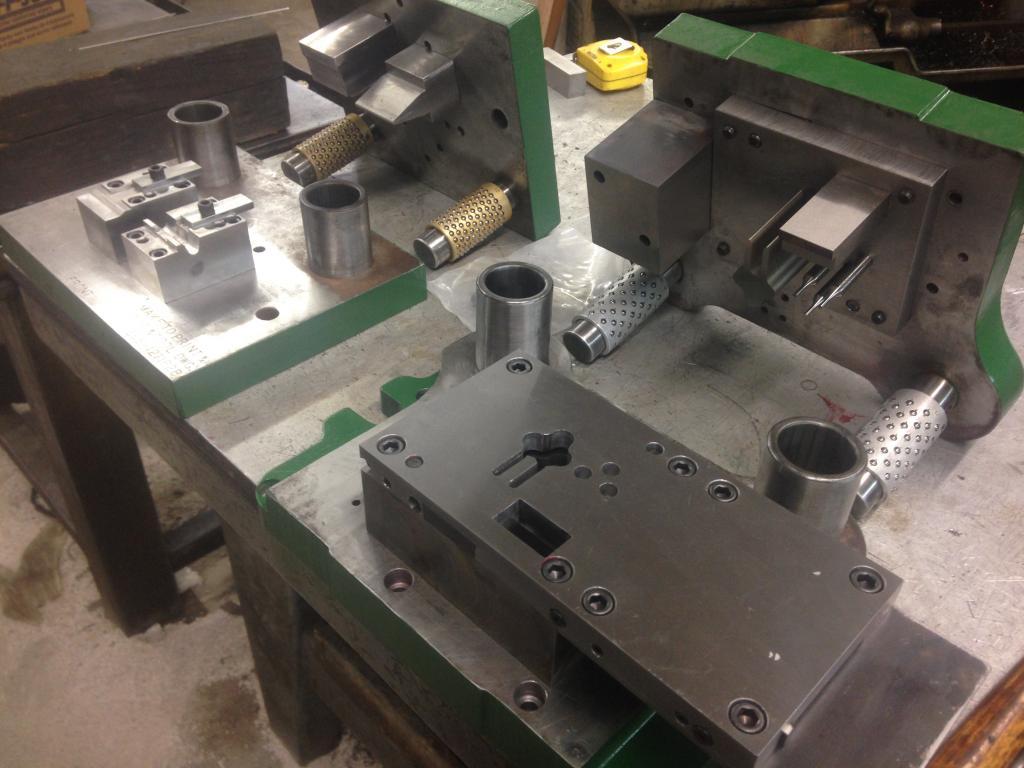

Here are some photos of the new dies and some blanked out hooks. Haven't had a chance to form the samples at the moment, but we will test the forming dies and heat treat once it is determined if any adjustments need to be made. My cousin Kevin Lumpkin of Lumpkin Tool & Die has performed yeoman's work in designing the new dies per Rock Island Arsenal Drawing #7137567 which calls for .105 material with .109 diameter hole. We will be able to turn out both brass and steel hooks/frogs on the new dies.

We are still a family run shop, only three of us, myself, wife Camille, and son Stuart age 17. We are still operating out of an addition to our old barn here in Clay, Alabama. A lot of the equipment I use here in the shop to turn out M1907 Slings either came out of one of the arsenals or is the same make and model vintage equipment that was used during WWI and WWII. All the leather M1907 Slings have the correct oblong holes and are punched on vintage reciprocating punch presses identical to the ones Boyt used during WWII. I have traveled the country over the past 25 plus years acquiring the vintage equipment we use everyday in the shop. But the most difficult part has always been hardware suppliers, two rivet companies and three hardware companies have either closed their doors or discontinued the hardware over the past 25 years. Kevin built the dies, but I guess I'll have to spend time at his shop punching parts and then Parkerize them just as I have the "D" rings for years.

Semper Fi,

Richard

Here is a photo of a M1907 sling using customers original WWI brass.

Our rivets are made to the original MILSPEC from 260 cartridge brass #13 Gauge wire on a button head wire forming machine as were the originals. The rivets are set using a rivet hammer and anvil as were the originals.

All equipment use to produce the slings are the same models and make as were used by Rock Island Arsenal, Boyt, Hickock, Enger Kress, ect.

Our creasing machine is a Randall Harness Mfg. 1887, and was one of the models that was used at the various arsenal harness shops. It has been documented as having come out of one of the arsenals, just don't know which. One of the key features to this machine is it is built backwards from the civilian models of that era, so it is easy to distinguish. It rolls the back (flesh) side of the sling and roll presses the crease down both edges of the sling on the grain side. This is a two step operation.

The sling is sewn with a Campbell Harness Stitcher (Needle Awl Machine) (Circa 1890s) serial number is in the range of some of the Campbells that were sold to the Ordnance Dept. in that era.

Our 18" fixed blade splitter was made by the International Harness Co., Cincinnati, OH, mfg in the late 1870s. Is has an arsenal inventory data plate braded to the cast iron frame, just don't know which arsenal.

Our punch machine is an Alva Allen 5ton, equipped with a cam operated reciprocating attachment, which indexes the strap for each pair of holes. I use three of these machines (set up for various operations), and they are identical to the ones Boyt used during their WWII production. These machines have been dated to the 1930s. All holes are the correct oblong type as on the original slings.

The thread used is NOS natural linen (wheat color) 8/4 MRT Left Twist, waxed as it passes through the machine.

Semper Fi,

RTInformation

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current.

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

PM

PM