Hi folks, thought I'd share this one with you, simply given the fun I had inletting the forend to receive the metal tab (or "hook").

The India-made forend came rather "naked" - it required inletting both for that hook, and for the semi-hexagonal shape of the barrel at the knox.

I started by drilling the two screw holes on the new forend, to make sure I was going to draw out the profile of the metal hook in the right spot.

i screwed the hook upside down to get a flat contact with the forend, to mark the contour.

I figured that doing all the inletting by hand was going to be time consuming and, given my hand carving skills, the result would probably end up unsatisfactory. What I needed was a milling machine. But, have you seen the prices on such tools?

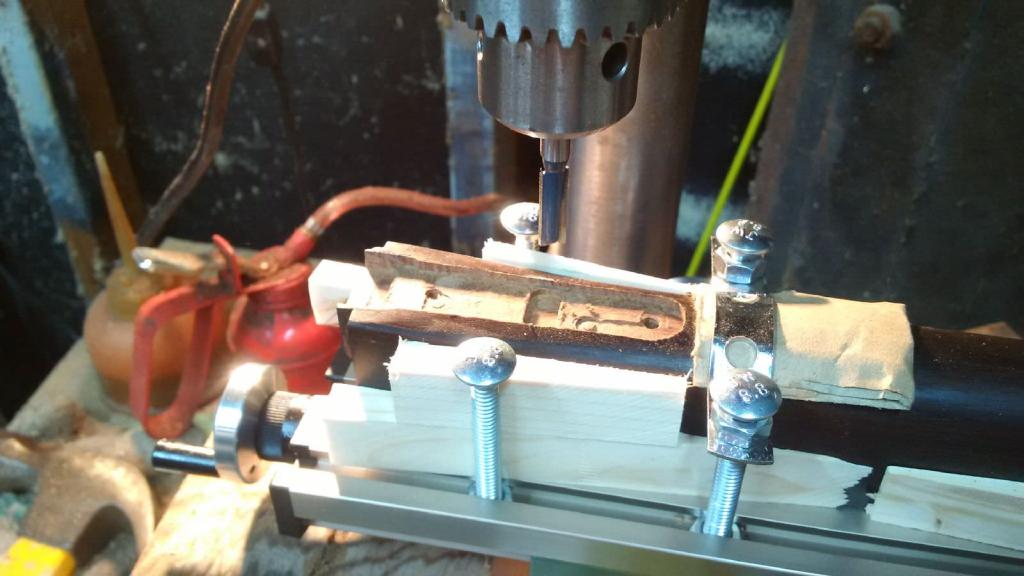

Cheap as I am, I started looking for alternatives. I do have a drill press, so... I found out that small milling "tables" exist. Some $120 later, I was set for some milling on that forend. I went for the "Proxxon micro compound table". I'Ve screwed it on a rectangular piece of plywood, and clamped that plywood in my drill press vise. I used a small, round router bit

for the inletting.

In this picture I had just started. The clamping of the forend is a rather... "homemade" affair but, it worked. Almost.

After I started the forend began creeping upwards. So I made a simple cross-member between two of the screws. You can see it in the following picture.

After that, final inletting was done with chisels. I'm pretty sure I saved some time, and it was fun too.

Information

Information

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current.

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

PM

PM