-

And there's another reason some barrels shoot better than others- Straightening before the final turning results in unbalanced internal stresses that are "built in". The lucky few barrels where everything went correctly were then most likely indifferently bedded...

Ever so reasonable to select rifles for sniper conversion by actually testing them! Not everybody (nations) went to so much trouble.

BTW, straightening finished barrels SOMETIMES works OK, other times, as in Son's example, they refuse to cooperate. I once straightened a 16" AR barrel that was used to pry open a door (about 5-10 degrees of bend!) that is still stupidly accurate after 20 years hard use. (Not exactly mine anymore, had to let the womenfolk have it.)

Last edited by jmoore; 01-11-2010 at 09:47 AM.

-

-

01-11-2010 09:35 AM

# ADS

Friends and Sponsors

-

Legacy Member

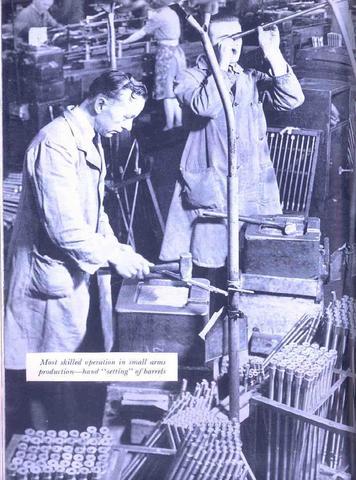

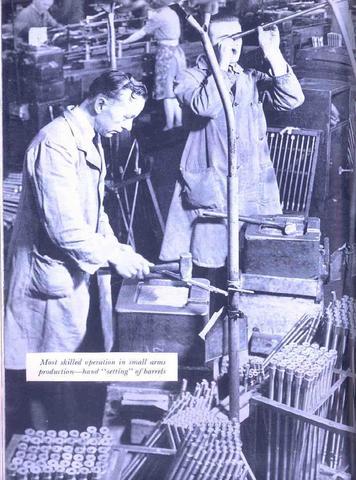

By this point skilled labour was very scarce and de-skilling jobs was pushed to the limit, often against ferocious opposition from the unions who would have fought long and hard to achieve working conditions and rates and didn't want to see them being diluted again. In many cases women were being employed who often never worked at all, let alone worked in engineering. Jobs were broken down into very simple steps- wish I'd retained one of the instruction cards I saw a few years ago. It was at a very basic level.

-

-

-

As I was lead to understand it, during the war, only expensive Bren and BESA barrels were straightened, and that was not by hammer but a press. Relatively cheap Rifle barrels were deemed straight if the last 6" were straight, using a 'GAUGE, testing, straightness of bore' and the 2" long GAUGE, plug bore .301" passed without hinderance.. but a whack of the muzzle onto the work bench was acceptable!

While on the subject of barrels, does anyone have a Mk3 barrel. This is one made in two pieces with the reinforce shrunk in place and retained with two cross pins. Also it's marked Mk111 or just 111 on the breeching up flat. If you look carefully, you can usually see a witness line where the sleeve meets but if not, then you will see the two retaining pin heads, about 1.9" from the breech face.

Another bit of useless info

-

-

Legacy Member

Barrel straightening at BSA

-

The Following 5 Members Say Thank You to Mk VII For This Useful Post:

-

Advisory Panel

Interesting bit of kit, the barrel setter's anvil. Wonder if any of those survived. Note the groove.

IIRC the TxtBk of SA 1929 says it was done by letting the barrel fall by it's own weight a leather covered block. No4 barrels required a bit more force perhaps.

-

-

Legacy Member

Originally Posted by

Son

Never seen that thread before or knew what forum it was on, but i can tell you it only took ONE guess & there it was, LoL.

-

-

Legacy Member

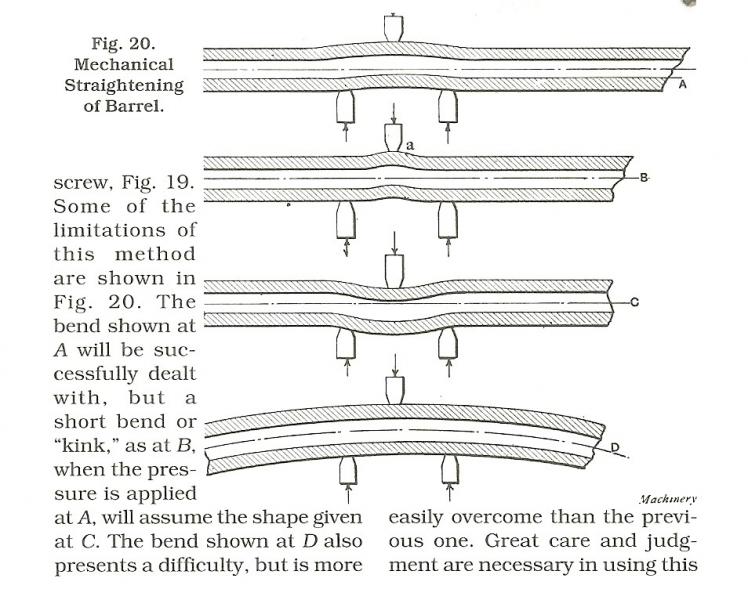

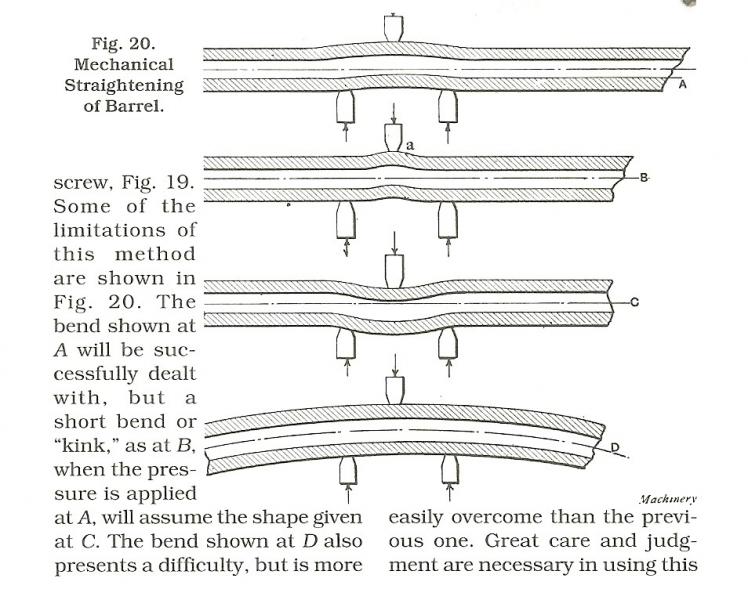

Straightening Machines

Again, from "Making Rifle barrels"

"the writer has tried this method, and can testify that excellent work can be done with the machine, but it is not nearly as fast as the hammer and block method. The impression prevails in some quarters that anyone can run one of these machines and straighten rifle barrels with it, but this opinion is erroneous in the extreme, inasmuch as no one but a rifle barrel straightener can use such a machine ........"

".......it is admitted by those who use both methods that machine straightening is not nearly as economical as hammer and block straightening, and that one man can do fully as much work by the latter method as three can do on a machine........"

Machine Straightening

-

-

Legacy Member

Originally Posted by

5thBatt

Never seen that thread before or knew what forum it was on, but i can tell you it only took ONE guess & there it was, LoL.

The same place that uses duct-tape to measure headspace, and credit cards and coke cans as bedding material

-

-

Dang, I use duct tape for bedding, and aluminum can material to measure headspace. No wonder I've been having so much trouble- I keep getting them mixed up!

-

PM

PM