-

DISCLAIMER: Stencollector has been kind enough to allow me to post and use his collection of material on building his SAS3 Sten, the actual gun used to get RCMP approval. The following is his work.

The mag well collar is manufactured it from 1/8" plate. Photo one shows the plate being bent around. The mandrel being used is an old roadwheel pin from a Brengun carrier, turned down to the outside diameter of the tube. The next photo shows it bent completely and before having the seam welded. The origionals were approx .105 thickness, although this varied between manufacturers. In another photo you can see where the outside of the tube is being turned to the correct thickness. The inside had to be bored slightly to provide a nice (but not loose) fit. The last photo shows the ejector port cut into it.

The port was accidently cut too long...had to weld a little metal back in place. The locator pin has already been drilled, and the magazine opening roughed into place.

Союз нерушимый республик свободных Сплотила навеки Великая Русь. Да здравствует созданный волей народов Единый, могучий Советский Союз!

-

-

01-24-2008 06:24 PM

# ADS

Friends and Sponsors

-

DISCLAIMER: Stencollector has been kind enough to allow me to post and use his collection of material on building his SAS3 Sten, the actual gun used to get RCMP approval. The following is his work.

Again, 1/8 sheetmetal was used. A mandrel the size of the internal magwell was made up and used to make the bends. Once the holes were cut for the mag release, and the front slot for the housing release, this piece was located and welded on to the tube that was made in the previous post. It was initially tacked it into position, then assembled onto the receiver to make sure that the gun would feed.

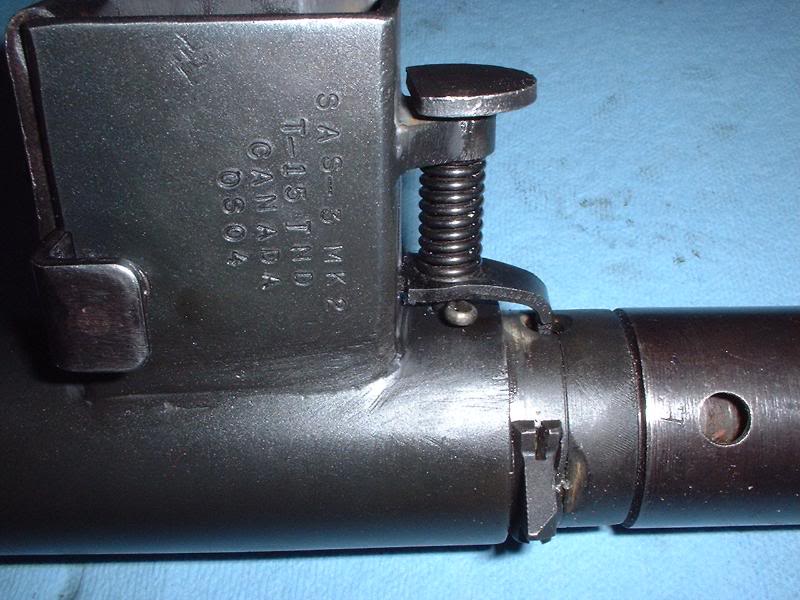

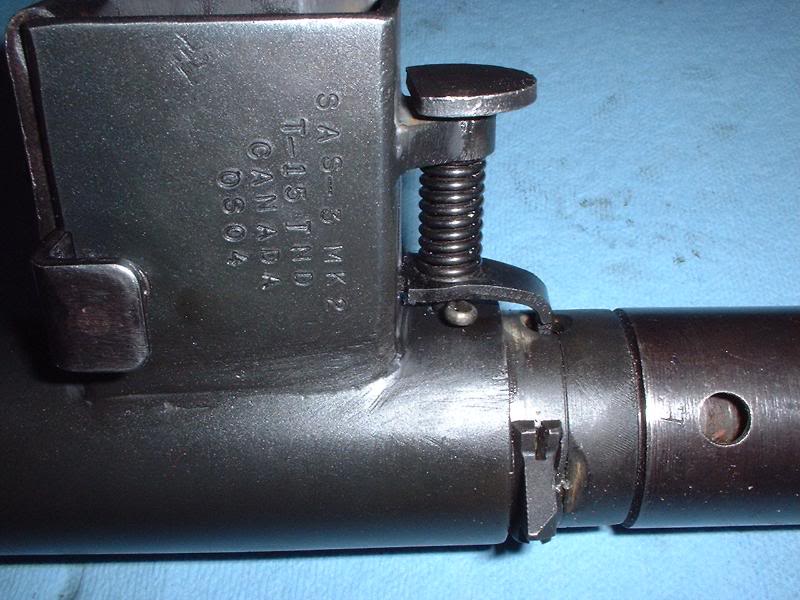

At first, the last round would continuosly jam. For whatever reason, the housing prefferred to be further back than on an original sten, so the welds were cut and the mag box was moved further back. The triangular bent barrel nut lock had to be custom made since this dimension has been changed by the repositioning of the housing. The last photos show the stamping of the markings on the housing.

This housing is stamped with the serial number 0S04. The serial was alsostamped onto to the tube and the trigger housing, since Stencollector was concerned that the ruling about what constitutes the receiver could one day change.

Союз нерушимый республик свободных Сплотила навеки Великая Русь. Да здравствует созданный волей народов Единый, могучий Советский Союз!

-

-

-

DISCLAIMER: Stencollector has been kind enough to allow me to post and use his collection of material on building his SAS3 Sten, the actual gun used to get RCMP approval. The following is his work.

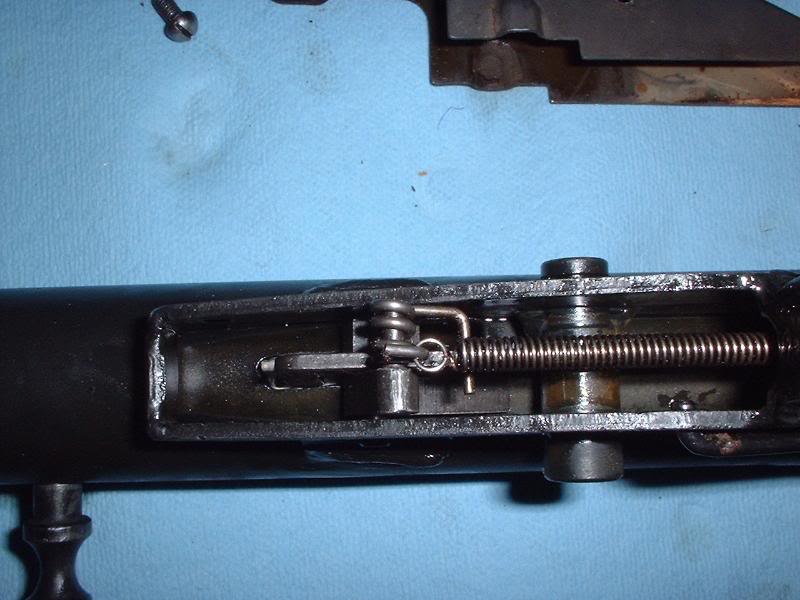

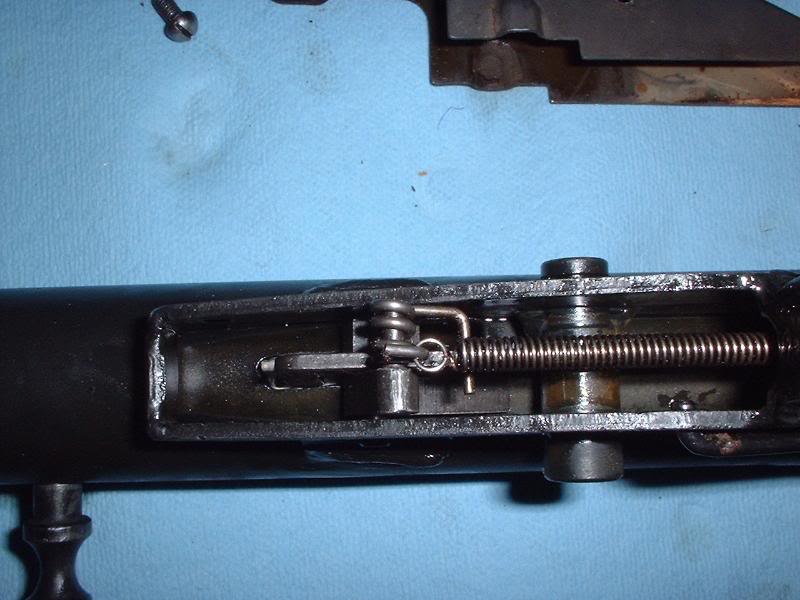

Here are the final photos of Stencollector's project. Photo 1 is of the dovetail filed in to the receiver. Photo2 is of the two main items with the trigger housing welded back on before refinishing. Photo 3, is of the components ready for assembly. Photos 4, 6, and 7 are the serial numbers located on the magwell, the trigger housing, and the tube. Photo 8 is a shot of the semi auto closed bolt system, which utilizes a AR-15 type firing pin. Photo 9 shows the trigger mechanism from underneath. The change lever has been welded from the top (before it was welded to the receiver) and the slot for the disconnect is cut so it does not allow any side-to-side movement. Any altering of the trigger mech to try and make it F/A will jus result in the gun jamming, as the round will not slide over the firing pin. The bolt was not built with feed lips like that of a normal sten.

Photo 12 shows the addition of metal to the barrel lock. Because the magwell was moved back 1/16" on the magwell collar, the barrel lock had to also be extended.

The remaining photos are of the finished product.

Last edited by Claven2; 01-24-2008 at 08:18 PM.

Союз нерушимый республик свободных Сплотила навеки Великая Русь. Да здравствует созданный волей народов Единый, могучий Советский Союз!

-

-

Advisory Panel

Thanks for posting these Claven. As you can see in the photos, I have no problem working with metal. But wood and computers are not my friends. I couldn't cut a 2X4 square if my life depended on it, nor could I post the photos as neatly as you have.

The nicest thing about metal is that if you make a mistake and take too much metal off, you can always just zap a little back on. The key to the magwell, in my opinion, is to first get the locating hole in place on the tube where the pin goes in to lock the magwell. Then you can cut the holes to match the piece of tube that is underneath. Use the original tube from the cut up sten receiver.

When you are making up the new receiver, same deal. Get that locating hole in the right spot, then pin on the remnants of a cut up magwell to the new receiver. Use it to make the magazine and ejection ports. Use the origional piece of tubing as a guide as to just how far you should cut. Note that the ejection port does not go all the way to the trunnion.

Some of this doesn't make sense to you? Just wait until you are starting to make your cuts...it'll all make sense then. Or after you've made a wrong cut. Then it'll really make sense.

-

-

Head Moderator

(Founding Partner)

Site Founder

Have you guys given any thought to making an adaptor to use the RRA 10 rd 9mm AR mags?

-

-

Advisory Panel

Considered it, but I did this to have a reasonable copy of the sten gun. If the RCMP had an issue with the sten magwell I built, I was going to make one that took Inglis browning mags. I have many, many sten mags, so it is nothing for me to cut down 20 or 30 to 5 rounds only. That way, whatever I have in my pocket is to it's full capacity.

If I really wanted to make a useful goofball variant, I would make it take the luger 32 round drum magazines.

-

-

Advisory Panel

Concerning shop made reamers - go to www.practicalmachinist.com, and in the gunsmithing forum there is a current discussion of "D" bits. All the information you would need to make these.

-

-

-

-

Now since the SAS3 kits are still not in-hand, just for fun, let's see what it takes to manufacture an SAS3 bolt assembly...

First you need some suitable round stock... and a mill... and patience... and, and, and...

(in other words, this is just for show, most guys shouldn't try this at home unless they are machinists)

First you center-bore the firing pin hole using a mill or lathe (lathe was used here) and then you use a mill to bore the guide rod holes. An end-mill cuts the cartridge recess and a small drill bit is used to cut the pin opening. Afterwords, you mill a flat which will eventually be feed lips.

Back into the mill, and....

Ta-da! Feed lips! (note they do NOT protrude beyond the cartridge recess face. Doing so would make it "go fast" under the right circumstances, which is illegal, so do not do that.)

And here the hammer recess is milled into the back of the bolt.

This bolt still needs the extractor and pin cuts made - it's not done. It'sa trial experiment or sample. The next one will go easier... if there is ever a "next one". Hopefully the SAS3 bolts are importable to save us all the trouble.

Союз нерушимый республик свободных Сплотила навеки Великая Русь. Да здравствует созданный волей народов Единый, могучий Советский Союз!

-

-

I'm sure the CFC will let you know if the serial you intend to use is taken or not. I'll probably use some random Longbranch formatted serial number myself.

The mill is an older Bridgeport. Manual, not CNC.

I was talking to a friend who is a gunsmith machinist, and he thinks we may be able to fabricate a series of mandrels and presses to form the mag boxes from seamless tubing, cutting down on ALOT of the work. It's a long-off possibility right now, but at some point maybe someone can offer a formed mag box and collar, unwelded, as a kit for prospective builders, an "80% receiver" of sorts.

Last edited by Claven2; 02-02-2008 at 02:33 PM.

Союз нерушимый республик свободных Сплотила навеки Великая Русь. Да здравствует созданный волей народов Единый, могучий Советский Союз!

-

PM

PM