-

Oversized Chamber Experiment

A continuation of earlier ponderings, but w/ actual results.

A fellow a while back was worried if his new Lee-Enfield was safe to shoot because of slight swelling near the base of the cartridge.

Well, as best as anyone could advise, it was perfectly OK to shoot. But I got me to wondering- How much is REALLY too much expansion to be safely contained by a new brass case in, say, a .303" SAA (British ) chamber?

) chamber?

As the 7.62x54R "Russian " is rather fatter at the base, and has a fairly similar rim thickness, just a bit shorter in length, it seemed an easy way to have a "radical" oversize w/o ruining a good rifle. (OD at the base is about 0.035" larger.)

" is rather fatter at the base, and has a fairly similar rim thickness, just a bit shorter in length, it seemed an easy way to have a "radical" oversize w/o ruining a good rifle. (OD at the base is about 0.035" larger.)

Shortened some cases and loaded a charge of powder rather too hot for a 303, but OK for the Russian round. Also grossly overloaded a 30-30 case w/ a standard max. 303 british powder charge (bullet seated about 0.030" deep).

Made a remote firing rig and had an otherwise VACANT range.

DON'T TRY THIS YOURSELF! DEATH IS AN OPTION HERE.

So first test:

Well, a grossly oversized chamber and 303 W-W and R-P brass seem to get along. (The R-P swelled back further than the Winchester.) Once fired 30-30 brass DID fail.)

LH-7.62x54r____________ RH-Shortened 303 British commercial mfg case

Case on the right side is the 30-30

Fired cases extracted normally, except the 30-30 rim was too small.

Going to section some cases for funsies.

Sorry for the sub-par photos. No borrowed camera today. (Plenty more pics, this is just a sample- they're all lacking in fine detail- phooey!)

No in depth study yet, but, overall, I'm surprised at the LACK of dramas. Even the ruptured 30-30 did no damage to the rifle, but a human shooter would likely have been scalped, due to the rifle design. (No gas baffle at all on the top of the action.) The brass is quite resilient it seems. More later...

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

Last edited by jmoore; 04-01-2010 at 09:25 PM.

-

The Following 7 Members Say Thank You to jmoore For This Useful Post:

-

04-01-2010 09:06 PM

# ADS

Friends and Sponsors

-

Banned

-

FREE MEMBER

NO Posting or PM's Allowed

Very interesting! Just don't reload those cases. I think they are on a one-way trip.

-

The thought had crossed my mind to reload them, but its not directly related to the original question of "how much oversize can a chamber be and still be usable"- at least for the person firing military or commercial ammo.

Oh, BTW , the barrel on the test mule is still 30" and kind of rough, which ought to maximize the loads on the case, plus running 0.311" bullets in a 0.310" bore.

Next steps, I think are to try some modded but unfired military cases. (Unfortunately, I've no new Prvi Partisan brass, but there is a little new loaded ammo left.) Also, a factory 30-30 round w/ the "EH" ring to center it and ensure "hard" contact against the bolt face.

I'm wondering if I should increase the powder charge to full max 7.62x54r levels. It doesnt seem to make much sense, though, as we're actually concerned w/ "303 British " loads, which have already been exceeded. (In a case that actually is a little smaller, granted, but that should just make things worse!)

" loads, which have already been exceeded. (In a case that actually is a little smaller, granted, but that should just make things worse!)

Going to try and section some cases, now that I haven't been up 25 hours straight, as was the case w/ the original post.

Last edited by jmoore; 04-02-2010 at 09:30 AM.

-

-

Advisory Panel

Thank you very much indeed, jmoore, for a brilliant demonstration of why, when using old service rifles, you should use neck-sizing only, on cases that have been formed in that particular rifle!

Patrick

-

-

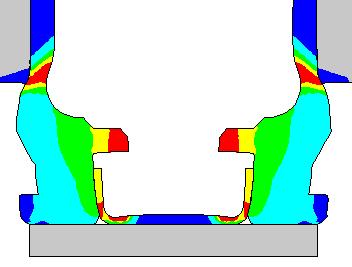

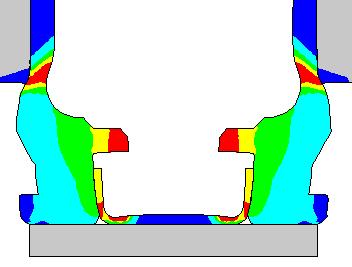

Sectioned test 303 British (shortened OAL to fit) cases. Note no signs of localized thinning. The W-W is on next to bottom, R-P bottom. Regular "new" 303 case second down. (7.62x54r on top!)

(shortened OAL to fit) cases. Note no signs of localized thinning. The W-W is on next to bottom, R-P bottom. Regular "new" 303 case second down. (7.62x54r on top!)

Maximum offset on sectioned cases is at top. Cases selected for sectioning by checking for max. offset in firing pin indentation on primer.

And, yes, the cases WERE a snug fit (base to shoulder) to minimize fore/aft (headspace) movements.

Last edited by jmoore; 04-02-2010 at 02:48 PM.

-

Thank You to jmoore For This Useful Post:

-

Banned

Originally Posted by

jmoore

The thought had crossed my mind to reload them, but its not directly related to the original question of "how much oversize can a chamber be and still be usable"- at least for the person firing military or commercial ammo.

Oh, BTW , the barrel on the test mule is still 30" and kind of rough, which ought to maximize the loads on the case, plus running 0.311" bullets in a 0.310" bore.

Next steps, I think are to try some modded but unfired military cases. (Unfortunately, I've no new Prvi Partisan brass, but there is a little new loaded ammo left.) Also, a factory 30-30 round w/ the "EH" ring to center it and ensure "hard" contact against the bolt face.

I'm wondering if I should increase the powder charge to full max 7.62x54r levels. It doesnt seem to make much sense, though, as we're actually concerned w/ "303

British

" loads, which have already been exceeded. (In a case that actually is a little smaller, granted, but that should just make things worse!)

Going to try and section some cases, now that I haven't been up 25 hours straight, as was the case w/ the original post.

Mr. jmoore

If your are referring to the "EH" ring as a rubber o-ring, I do not claim credit for it, the rubber o-ring method of fire forming cases was first posted by a Canadian at the old Jouster

at the old Jouster forum several years ago.

forum several years ago.

At the time I personally thought of it as a "bubba" idea at best and did not try it for some time. Then one day after kitting a Delta faucet with new o-rings the light bulb came on and I slipped an o-ring around a .303 case and the next day put the Canadian idea to test.

Now I think the rubber o-ring is the best idea since buttered bread.

Without the rubber o-ring and zero head space you get this type of case stretching.

I wish you would take some gauge readings before and after to get more than a "eyeball" reading of your cases.

Hint, hint......

Base diameter before and after hint, hint.........

Did you put a lot of firecrackers under tin cans, light the fuse and and run like heck when you were younger just to see what would happen?

-

I wasn't allowed firecrackers or toy guns (no real guns in the house either).

See what happens when children are denied access to something?!!

If you don't want credit for the O-rings, that's fine.

All that fancy computer graphic stuff STILL doesn't give me an idea as to how oversized a chamber must be to create a likely case failure. Hence the "real world" (if low buck) experiment. Still have multiple scenarios to try, this was just a first step. Hopefully it will be of at least a LITTLE use...

Base dia didn't grow that can be measured w/ calipers. Nor do I have a set of blade micrometers, even at work, that measures in "tenths". Regular micrometer doesn't fit any more at the base due to the bulge even though it is a bit fwd.

To make useful case wall thinning measurements I needed a point of reference at which to return after firing, due to the thinning of the walls going forward. Plus I sold my handy-dandy RCBS case check stand a real long time ago, as it was no longer being used after the first flurry of activity. Time for another, I reckon. Too much trouble to build a dedicated rig, and I don't want to re-invent the wheel every test run.

Primers LOOKED normal after firing, FWIW. (Oooh, acronym thing. I'm getting all computer-y.)

Last edited by jmoore; 04-03-2010 at 04:22 PM.

-

-

Legacy Member

>>>And, yes, the cases WERE a snug fit (base to shoulder) to minimize fore/aft (headspace) movements.<<<

Did you check the case length before and after firing?

I wonder if they got a little shorter when they inflated.

-

-

I'm "a'fixin' " to do a batch of military ammo. Pull bullets, carefully remove powder charge, shorten/ neck size case, and replace components. Will check for case shortening this time- it had occured to me, but it wasn't directly pertinent to the question of whether the cases would hold together.

Next batch tally:

Prvi Partisan- new

South African- 1980's vintage

Pakistani- 1960's (It all fires, but every one so far has a bit of delay! Shouldn't affect the test.)

Radway Green- 1950's (Unknown quality)

Scheduling: soon- but its some tedious loading and shooting! Takes away from "real" trigger time.

(Plus, need an empty range- haven't yet built an enclosed test stand- and hopefully won't need to!)

ETA: May try a factory 30-30 offset and "o-ringed", plus possibly a max 7.62x54r load, but not too sure why!

Last edited by jmoore; 04-05-2010 at 01:27 AM.

-

) chamber?

" is rather fatter at the base, and has a fairly similar rim thickness, just a bit shorter in length, it seemed an easy way to have a "radical" oversize w/o ruining a good rifle. (OD at the base is about 0.035" larger.)

PM

PM