-

Advisory Panel

Source?

ANSI/SAAMI industry standards for the manufacture of firearms and ammunition.

Item #206 Z.299.4 1992

ANSI/SAAMI Centerfire Rifle

(Page 63)

"Chamber Full Size" drawing provided by E.Horton. Original source?

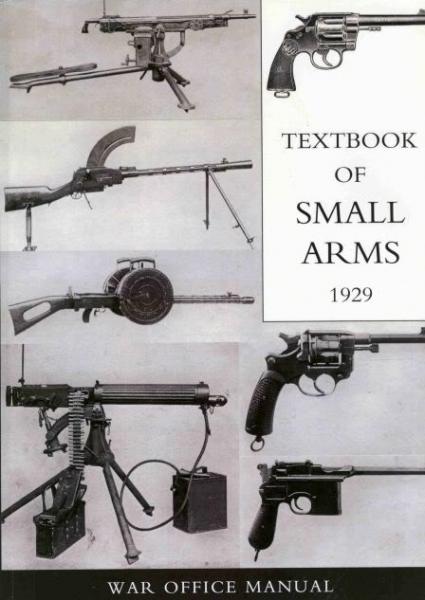

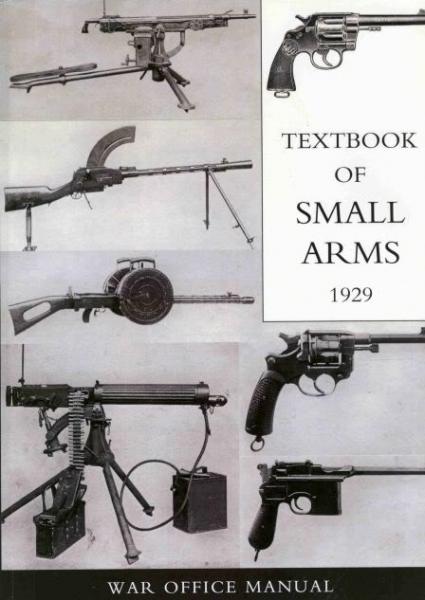

Unless too far forward for easy chambering, shoulder position is largely immaterial with rimmed cases in sound arms. Contrary to beliefs often stated, rimmed case unsupported at shoulder does not "blow forward" and elongate, but rather expands radially - and shortens. (Elongation occurs primarily during full-length sizing of expanded fired cases, added to any sidewall stretch resulting from end-play before firing with case and chamber clean.)

-

The Following 3 Members Say Thank You to Parashooter For This Useful Post:

-

04-05-2010 12:33 AM

# ADS

Friends and Sponsors

-

Banned

45-70 chamber pressures:

Trap Door 1873 Springfield = 18,000 CUP

1886 Winchester & 1895 Marlin = 28,000 CUP

Ruger No.1 & No.3 = 40,000

I didn’t grease my cases or bullets for my 45-70 Ruger No.3 when I was shooting 300 to 500 grain jacketed bullets at 40,000 CUP.

Normal chamber pressure with black powder and the 45-70 is 18,000 CUP or less so case head separations would be a rarity. I never had a 45-70 case head separation in a dry chamber in my No.3 Ruger either.

When I shoot cast bullets my cases are NOT greasy and my lubed bullets are “inside” the case and crimped in place.

(bullet lube sealed inside the case where it belongs)

South African military surplus.

The unfired South African cartridge in a Wilson case gauge (SAAMI chamber) .002 under minimum head space as required. The case rests and is head spacing on its shoulder and not the rim in this gauge. SAAMI cartridge case shoulders should be .002 shorter than minimum head space (even on a rimmed case)

Fired case sticking approximately one eighth of an inch above the SAAMI gauge. This shows how much deeper the military Enfield chamber is compared to SAAMI or CIP chambers.

Brand new Remington case in the Wilson case gauge, the case shoulder is a quarter inch too short and is blown out even further in the military Enfield chamber. (the case should be just .002 below the lip of this gauge)

"So I advise everybody to stop worrying about specifications of arguable origin, validity and applicability, and simply form their real brass to fit their real rifles, not theoretical values. I am intrigued by the theory and the engineering problems that have been thrown up in this thread, but I also want to shoot my rifles!"

Patrick Chadwick

Theoretical and actual are two different things.

Ed Horton

Last edited by Amatikulu; 04-05-2010 at 06:46 AM.

-

Originally Posted by

ireload2

JM,

Do your chamber shoulders remotely resemble the shape of unfired ammo?

Not really, hence the various "families". But there's some little differences even in the ammo, however, I never catagorized them.

W/in a particular family, I have a few rifles that can interchange neck sized only rounds, but it's generally easier just to segregate by S/N. Which can be right annoying during a busy range day! I'm really starting to miss cheap "non-reloadable" surplus ammo....

Last edited by jmoore; 04-05-2010 at 02:25 AM.

-

-

Advisory Panel

Old quote from the engineering world:

"Theory is when it ought to work, but doesn't. Practice is when it works, but nobody understands how"

Patrick

-

-

Legacy Member

In theory, theory and practice are the same. In practice they are not.

The theory that cases with a little bit of lube or oil will damage your rifle is just that. At one time or another all rifles are fired with a film of oil in the chamber.

BTW all my cast bullets, and there have been tens of thousands of them since 1972, have been lubricated grease groove bullets. In most of my loads there is/are exposed grease and grease grooves on the bullets. When fired some of the grease is left in the chamber and it leaves a film in the bore. It eventually gets on the case too. No big deal ever.

Parashooter is right about case shoulder expansion. The annealing halo remains in the same location and the shoulder blows outward unless the brass is very hard.

Last edited by ireload2; 04-05-2010 at 07:26 PM.

-

-

Banned

Originally Posted by

ireload2

Does anyone have a fully dimensioned drawing of the .303

British

maximum cartridge as standardized to be fired in Lee-Enfield rifles?

I need the max cartridge drawing so I can compare it to the minimum standard .303 rifle chamber. Thanks

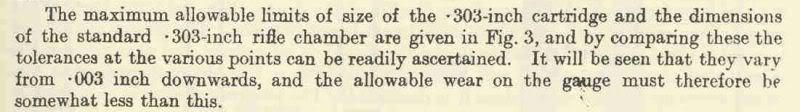

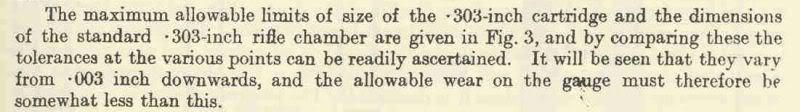

From the "1929 Textbook of Small Arms"

-

FREE MEMBER

NO Posting or PM's Allowed

I have reloaded for a number of Lee Enfields. Fazakerley No 4 Mark 1 and 2, Long Branch No 4's, Lithgow No 1 Mk III's , and one Savage No 4 Mark 1*.

No 1 Mk III's , and one Savage No 4 Mark 1*.

The shoulder profiles on the fired cases have any number of different shapes, from sharp angles to smooth curves. The shoulder distance from the base is as varied as the autumn leaves.

I gave up trying to measure headspace on these things as all headspace greater than my American gages.

About the only thing common to the chamber of these rifles is that they will fire factory ammunition.

-

Advisory Panel

Edward, that is a very interesting book cover. Looks like a Colt New Service revolver on the top right. But I can see the cylinder latch, which is on the left side of the frame on my revolver. And I think I can just about see the O as the next-to-last letter in the logo on the grips. Have my eyeballs finally given up, or is that truly a reversed picture of the New Service?

Patrick

-

-

Banned

-

Funny thing, that maximum cartridge drawing above. Check out the maximum base dimension.

-

PM

PM