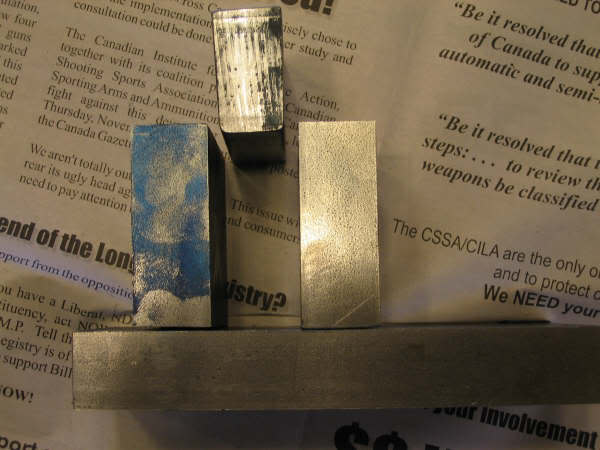

There are various ways of fabricating the box portion of the magazine housing assembly: one piece wrapped around a form, with a single welded seam, as Stencollector showed in his photo series; three pieces hand formed as illustrated elsewhere in the thread, and welded together; die formed and seamed; formed from seamless tubing. Earlier photos showed a shaped plug which could be used for any of these methods. It is dimensionned so that it is a tight fit in a demilled housing. Note that a taper is incorporated, front to back. These photos show the basic pieces for a die to be used in conjunction with the forming plug. A press is used in conjunction with the plug to force a steel strip into the die, and then the ends are folded over and a single seam run up the back. These pieces are cut from a piece of 1"x3" steel. Dados will be milled across the base, and the sides secured in these cuts. Note that each sidepiece will be machined with a taper, to match the forming plug. One of the sidepieces will be machined on both sides, so that either 3/32" or 1/8" steel may be utilized for the housing, simply by reversing the part.

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

PM

PM