A SAS3 Sten uses tubing with an OD of 1.500", and a wall thickness of about 3/32" or .093" to prevent an original bolt from being inserted into the tube.

The original Sten recoil spring guide and barrel block won't fit, as a result. It is necessary to alter either the tube, or the parts - the tubes that come with the kits are relieved inside the rear of the tube for the spring guide, but NOT for the barrel block as the kits are meant for MkIII repros, not MkII's.

Because this lathe (a 13x40 Standard Modern) will not pass a 1.5" diameter piece through the spindle, so the steady rest is used to allow the ends of the tube to be bored out.

An aluminum plug with a centered hole was made which is a tight fit in the tube. One end of the tube is mounted in the chuck, the other end is supported by the tailstock centre. The steady rest jaws are then adjusted against the tube. Once adjusted, the centering plug is knocked out, and the boring bar is then used to bore out the tube enough to clear the barrel block and spring guide.

See kids - shop class WAS useful!

Here is the SAS3 bolt with a reproduction MkII cocking handle fitted.

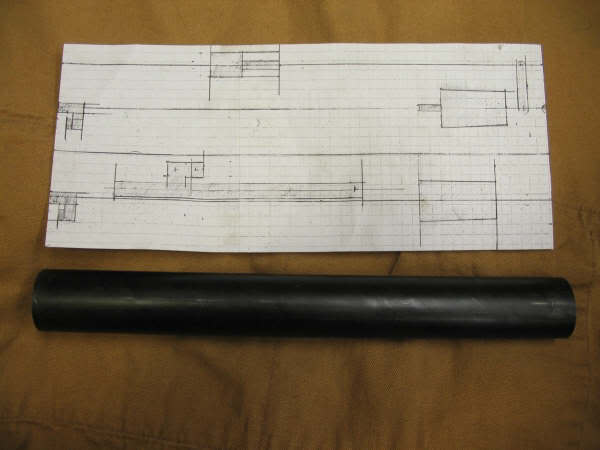

Here is the blank tube and a template. The template is bonded to the tube, and then the openings are milled out. An alternative would be to coat the tube with machinst's blue, and scribe the lines onto the tube.

The SAS3 kit comes with a template already bonded on, but it is a MkIII tamplate. It is sometimes easier to start with a new template made from STEN drawings than to bother modding the SAS3 template.

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

PM

PM