-

FREE MEMBER

NO Posting or PM's Allowed

Problem with Stuck Brass

Hello everybody,

This is my first time being on this site, and I have to say it is truly an excellent resource. Anyways, on to my problem. I purchased and restored a 1944 Long Branch No. 4 Mk I (Serial 80L4183) not too long ago. After doing some restoration work, everything seemed to be in working order until I fired a couple of rounds through it and I have found that after the round is fired, the bolt seems to get stuck approximately 1/4" back from the beginning of travel and it takes some serious pulling to dislodge the bolt and brass. Any thoughts on what the problem could be?

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

05-10-2010 07:02 PM

# ADS

Friends and Sponsors

-

Legacy Member

Clean, clean and clean some more. Try putting a brass brush on a drill, soak with a good solvent and run in and out of the chamber. A good cleaning with hot water will also help with corrosive build-up. That should help.

B

-

-

Banned

Taco Joe

Can you take photos of the fired case and chamber and is the chamber actually pitted, rusted and even need brushing and cleaning.

The reason I'm asking is because from the limited information given we are really straining our psychic abilities and unfortunately this makes our long distance healing of your Enfield nothing more than guess work.

-

Advisory Panel

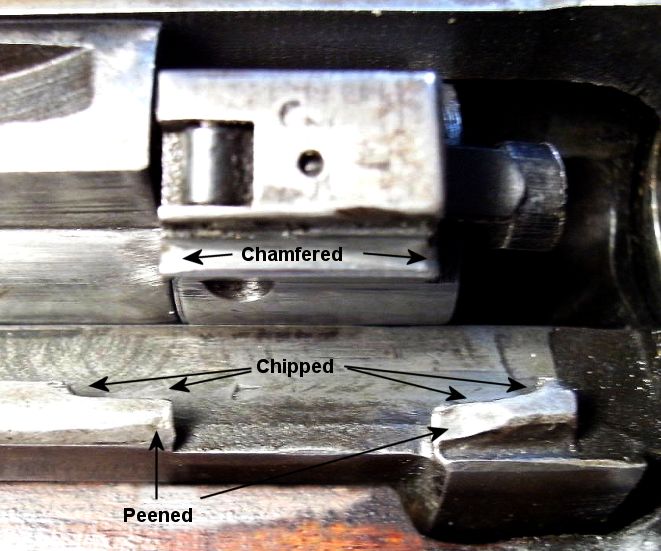

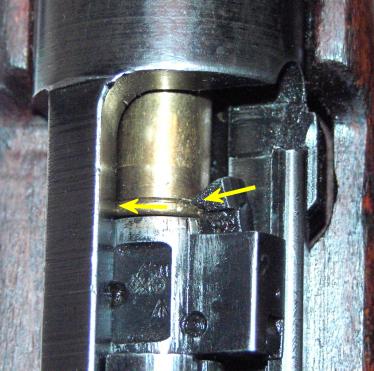

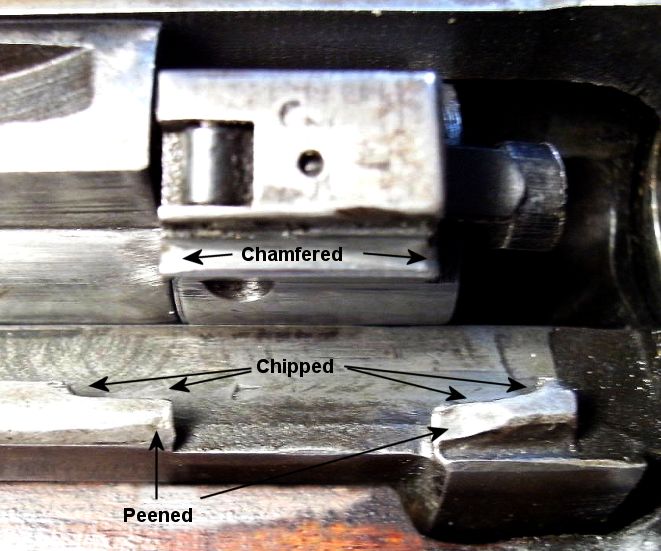

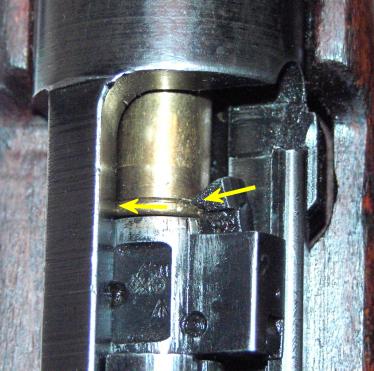

1/4" back of bolt-closed is near the point where the bolt head crosses the dismount notch on the No4 Mk1* guide rail. It's possible the rail is damaged and/or the bolt head's rail groove is not chamfered. With a cartridge present, the extractor spring urges the bolt head toward the rail, possibly explaining the occurrence of the malfunction only when extracting a cartridge. Try pressing the bolt head down and to the left (away from the rail) during extraction. If the problem is alleviated, you may have identified the source.

An extreme example of a damaged No4 Mk1* guide rail, also showing chamfered groove.

-

The Following 3 Members Say Thank You to Parashooter For This Useful Post:

-

Banned

Originally Posted by

Parashooter

1/4" back of bolt-closed is near the point where the bolt head crosses the dismount notch on the No4 Mk1* guide rail. It's possible the rail is damaged and/or the bolt head's rail groove is not chamfered. With a cartridge present, the extractor spring urges the bolt head toward the rail, possibly explaining the occurrence of the malfunction only when extracting a cartridge. Try pressing the bolt head down and to the left (away from the rail) during extraction. If the problem is alleviated, you may have identified the source.

Your psychic abilities are far superior to mine Mr. Parashooter

(I don't have any No.4 Mk.1* with a damaged guide rail and that thought never entered the synaptic network)

Signed brain dead Ed

Last edited by Amatikulu; 05-11-2010 at 07:55 AM.

-

Advisory Panel

Good thought Parashooter. Obviously not case adhesion.

Best make sure your bolt head guide slot is chamfered like the photo. If not, file it as above.

“There are invisible rulers who control the destinies of millions. It is not generally realized to what extent the words and actions of our most influential public men are dictated by shrewd persons operating behind the scenes.”

Edward Bernays, 1928

Much changes, much remains the same.

-

-

I'd say that it was a pitted chamber. JUST after the primary extraction is the point at which the bolt leverage cannot assist the unseating of the case from the chamber any further. This is fine with a smooooooth chamber but if it's pitted........ After that, it's brute force and higorance!

-

-

FREE MEMBER

NO Posting or PM's Allowed

Sorry for the delay gentlemen, I've been busy moving this week. I've looked at the chamber, and right now I can't really see any pitting (pics to come soon) or anything else in there.

As for the spent brass, there were no markings on them that would indicate anything unusual, I'll try to get pics uploaded in the next few days.

Parashooter, the dismount notch and the guide rail do not appear to have any damage and the bolt can easily slide through it. So I don't think that could be it, but I will try holding it like you said the next time I shoot it if it happens next time I shoot.

I was thinking through, would residual packing grease stuck inside the chamber cause this to happen? I thought that maybe I got rid of it all as it will extract rounds that haven't been fired with no problem at all. But maybe the heat would melt anything left inside and then it would cause it to stick?

Either way, I'm going to strip the gun again and focus on ensuring that there's nothing inside that chamber.

Thanks again for all of your responses!

-

Advisory Panel

OK, one more possibility. As the bolt is pulled back, the extractor forces the case to the left, where it drags against the receiver wall. (This friction is what normally ejects the empty case - long before the rim could strike the ejector.) If the extractor spring is strong and the wall is rough and/or dry, the resultant friction can retard bolt movement significantly.

Try smearing a little good grease on the wall where the cartridge rim drags. If that makes things better, polishing the site of the friction may help, as may keeping it lubed.

-

-

Banned

What brand/type ammo are you shooting, new commercial factory ammunition or surplus.

Register To Reply

Register To Reply