-

FREE MEMBER

NO Posting or PM's Allowed

Ballistol is my favorite for corrosive cleaning. I shot a ton of corrosive Russian ammo in an AK I had. As long as I cleaned with Ballistol I never saw any corrosion and I live in a humid area.

ammo in an AK I had. As long as I cleaned with Ballistol I never saw any corrosion and I live in a humid area.

-

06-13-2010 11:19 AM

# ADS

Friends and Sponsors

-

Legacy Member

When I were y'ung lad living in cardboard box.....

We cleaned our SMLE barrels by using the approved funnel to guide copious quantities of boiling water down the barrel. (the trick was to avoid any water getting anywhere near the woodwork). As I have not shot corrosive (mil spec, chlorate based) primers in my Lee Enfields since about 1975, it is not so much of an issue any more.

Some time in the 1960s, the RAAF apparently started using dilute phosphoric acid for barrel washing on their rifle ranges. Anyone else heard about this? Probably safer than scald burns and runaway fires on the range, too.

The mercury is in the "fulminate" component of the priming compound. I suspect that the reason it was used almost exclusively in "British " .303 ammo is that, if manufactured and stored correctly, it will ignite at any temperature found on the planet. Lead based primers are (or were) more fussy about extreme cold. Mercury will not adversely affect your rifle, however, from the instant of ignition, your brass is doomed. The mercury metal liberated on ignition instantly bonds with any brass it contacts and starts breaking the bond between copper and zinc, hence embrittlement. Those of us who grew up reloading the stuff very quickly got used to cracked necks during bullet seating. We resigned ourselves to not picking up cases after even the first reload, because of the rapid rate of failure during subsequent reloads/firings.

" .303 ammo is that, if manufactured and stored correctly, it will ignite at any temperature found on the planet. Lead based primers are (or were) more fussy about extreme cold. Mercury will not adversely affect your rifle, however, from the instant of ignition, your brass is doomed. The mercury metal liberated on ignition instantly bonds with any brass it contacts and starts breaking the bond between copper and zinc, hence embrittlement. Those of us who grew up reloading the stuff very quickly got used to cracked necks during bullet seating. We resigned ourselves to not picking up cases after even the first reload, because of the rapid rate of failure during subsequent reloads/firings.

That is why the cups for mercuric primers are made using heavy COPPER cups, not reactive brass. Note also the size of the cup (.250") compared to what we now consider a "large" primer, (.210").

All of which comes back to the principle that military firearms are usually built around a cartridge, thus the striker specifications on your basic Lee Enfield ( and P-14) were set to work with mercuric / chlorate based primers with copper cups. Note the striker / boltface changes when the P-14 became the M-17.

The fulminate gets things going and the chlorate adds "brissance", the extended flash that ensures ignition of the powder. Very important when you are loading ammo with compressed bundles of long propellant sticks. Granulated, double based propellants are a lot easier to ignite consistently than the old long stick "Cordite". Note that "contract" .303, (US especially) was loaded with granular propellant and lead-based primers. It is still CORROSIVE, however, as it contained chlorate as per above.

The .30 M1 Carbine cartridge was the FIRST military cartridge in the world to be specified and mass produced with non-corrosive primers. Why? the gas system is "non user-maintainable", unlike the M1 Garand.

Carbine cartridge was the FIRST military cartridge in the world to be specified and mass produced with non-corrosive primers. Why? the gas system is "non user-maintainable", unlike the M1 Garand.

Why the slow uptake of non-corrosive primers? Reliability at all temperatures and under all storage conditions. Once again, "surplus" ammo is often "surplus" for a reason, usually poor performance in batch testing.

-

Thank You to Bruce_in_Oz For This Useful Post:

-

-

Legacy Member

-

-

FREE MEMBER

NO Posting or PM's Allowed

Originally Posted by

TerryS

Sorry !

lol, I didn't mean to sound upset with you lol

now let us boogie!!!!!

-

FREE MEMBER

NO Posting or PM's Allowed

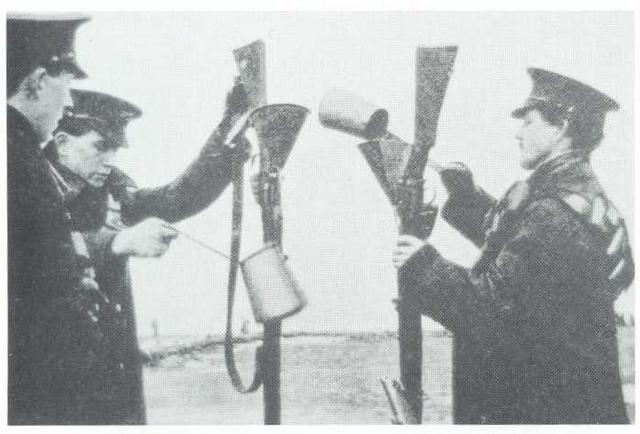

There was a fellow in Canada who had a quantity of the galvanized steel funnels used by British

who had a quantity of the galvanized steel funnels used by British troops to clean their rifles with boiling water. From what I gather, one of these funnels was issued to each squad, and after brewing up their tea, the men would use the funnel to pour a pint or so of boiling water down the bore, and then use their pull-through to run an oiled patch through the bore.

troops to clean their rifles with boiling water. From what I gather, one of these funnels was issued to each squad, and after brewing up their tea, the men would use the funnel to pour a pint or so of boiling water down the bore, and then use their pull-through to run an oiled patch through the bore.

I bought one of the funnels several years ago, and it works great. When I go to shoot my No.4, I take a quart-size thermos bottle full of hot water with me to the range, and after shooting, use the funnel to pour the hot water down the bore. By the time I get home, the barrel has cooled off a bit, and I run a patch wet with Hoppe's Number 9 through it, followed by one or two dry patches, and I'm all done. Elapsed time, maybe 5 minutes.

-

Legacy Member

-

Thank You to Mk VII For This Useful Post:

-

(Deceased April 21, 2018)

Those funnels are GREAT and they work with ANY rifle that uses milsurp mercuric primers.

I bought a wooden CRATE of them out of Canada many years ago. Aside from several friends and keeping one for myself, Nobody wanted them, so I had a dealer friend take them off my hands. But NOW it's a different story.

many years ago. Aside from several friends and keeping one for myself, Nobody wanted them, so I had a dealer friend take them off my hands. But NOW it's a different story.

To elaborate on the previous posts, every barrel contains microscopic cracks. Firing the rifle drives the salts into those cracks. BOILING HOT WATER expands the cracks, washing out the salts.

The ammonia in windex ONLY works on copper fouling.

Possibly fitting a copper tube to a metal funnel and flattening the funnel on onr side could be a substitute. though I think there is still a dealer in Canada who has the real thing.

-

This is still the British Army maxim - if you'll excuse the pun.

Army maxim - if you'll excuse the pun.

TREAT ALL AMMUNITION AS ERROSIVE AND CORROSIVE

-

-

(Deceased April 21, 2018)

I looked at the first post again, POF ? Other wise known as Poor Old Fodder.

? Other wise known as Poor Old Fodder.

The stuff I have encountered is mostly click....Bang or simply CLICK!

I have around 500 rounds that were given to me by a dealer friend. It was returned to him by the people who bought it along with a rifle. They finally gave up when waiting after the click, they ejected a round and it went off before it hit the ground

ammo in an AK I had. As long as I cleaned with Ballistol I never saw any corrosion and I live in a humid area.

Register To Reply

Register To Reply