-

FREE MEMBER

NO Posting or PM's Allowed

Originally Posted by

Son

Very slight alteration to Mr Horton's post if I may... The inner band screw should be tightened up to lock. The screw itself has a shoulder at the depth of thread to lock against. This leaves the length of the larger diameter from the shoulder to the head of the screw for the spring, the washer inside the foreend and the thickness of wood of the foreend.

To test, do as Mr Horton describes above. If it doesn't move, then something else is wrong... not the tension of the screw.

I also believed that the screw should be bottomed against the shoulder. With the upper guards and nosecap removed I can loosen the screw and the inner band is free to move, rattle even. Tightening the screw will pull the muzzle noticeably upward.

If the thunderstorms stop I will try adjusting the tension of the inner band screw. Right now my backyard range requires a canoe to get to the targets 8^(

Thanks everyone for the info, very helpful.

DAve

-

06-22-2010 10:56 AM

# ADS

Friends and Sponsors

-

Banned

-

-

FREE MEMBER

NO Posting or PM's Allowed

Originally Posted by

Edward Horton

My apologies, after reading the above postings and Sons very polite "Ed you have a few loose screws"

I searched every Enfield book and manual I have and they all say the inner band screw should be tightened until it bottoms out but be free to move up and down.

(Moral of story, NEVER ever argue with

Ian Skennerton

or Son the Ozmanic) BUT the Australians do cheat at Yacht racing, Rugby and Soccer.

Ian Skennerton

Ian Skennerton

Small Arms Identification Series No.1

.303 Rifle, No.1 SMLE Marks III & III*

ASSEMBLY.

"Inner Band: Spring should have slight play when screw is tightened up.

(Test with pressure with large screwdriver)"

Hmm, so when I bottom out the screw the inner band is no longer free to move up and down. I need to look at the bedding in that area again.

DAve

-

Advisory Panel

Originally Posted by

Edward Horton

BUT the Australians do cheat at Yacht racing, Rugby and Soccer.

"[/COLOR]

We don't play soccer..... do we? Oh, hang on- we must. I spotted this news clipping the other day...

The Socceroos visited an orphanage in South Africa this morning. "It's so good to put a smile on the face of people constantly struggling and facing the impossible" said Jamal Umboto, aged 6.

-

Thank You to Son For This Useful Post:

-

Banned

Originally Posted by

yellowhousejake

Hmm, so when I bottom out the screw the inner band is no longer free to move up and down. I need to look at the bedding in that area again.

DAve

yellowhousejake

I did not trust my memory after reading Sons posting, my problem is I can't find what I thought I read about not over tightening or bottoming out the inner band screw and only tightening until spring compression is felt.

Until I find it in writing and can post it here, I would trust Sons statement on the adjustment of the inner band screw.

I'm still looking for it in writing BUT Son has far more experience bedding the No.1 than I have.

BUT the U.S. Soccer team seems to know more about Soccer than the Australians do. (The revenge of "Quigley Down Under")

-

Contributing Member

I agree with this statement: "... the front spring loaded plunger [is] to ensure uniform contact w/ top of the barrel hole in the nosecap...". Now, if I have understood you correctly, the tip of your barrel is free floating in your nosecap? That could well be the problem; as far as I know, the principle of free floating SMLE barrels works only with heavy barrels, if at all, and contact with the nose cap is the correct set-up to damp down barrel flip. Now, I am not an expert, but that is what I understand. You can get a new nosecap (part 1A) for $6 - $9 from http://ssporters.com/parts/ENFIELD1.htm and also can get a .045' front sight blade for $1.50 from the same source.

-

-

Advisory Panel

The muzzle end must contact the foreend for about the last two inches with about 4 to 6 lbs of force required to separate them without the nosecap. The barrel centering stud is only there to maintain some upward thrust on the barrel if the foreend begins to warp away from it. Both it and the inner band were only there to reduce the effect on accuracy by a warping foreend, thus removing the need to have the rifle repaired/ re-bedded.

Here's a pic of a foreend just removed from the rifle to clean out the factory grease. You can clearly see the contact areas at the barrel knox, then about 1/2 to 1 inch either side of the inner band, ending with up at least a few inches at the muzzle. This one has continuous contact from the inner band to the muzzle and shoots better than I can.

All of this is irrelevant if the receiver isn't bedded properly.

-

Thank You to Son For This Useful Post:

-

Was that a standard barrel in it? ie. not a heavy

-

-

Banned

-

Advisory Panel

Was that a standard barrel in it? ie. not a heavy

Yes mate, standard barrel.

It is a '55 FTR Lithgow and was unfired at that stage.

and was unfired at that stage.

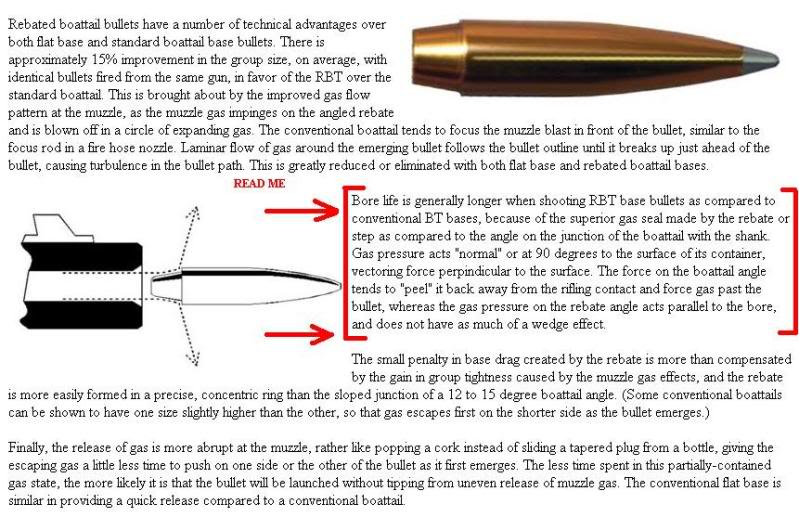

Mr Horton, another great technical post! Cannot recall seeing differences in intermediate ballistics explained as clearly.

Just to add, here's an amazing photo a mate took that helps demonstrate the moment of gas escape as the projectile exits the bore.

Last edited by Son; 06-24-2010 at 07:09 AM.

Reason: pat on the back for Mr Horton and add a pic.

-

Register To Reply

Register To Reply

I searched every Enfield book and manual I have and they all say the inner band screw should be tightened until it bottoms out but be free to move up and down.

I searched every Enfield book and manual I have and they all say the inner band screw should be tightened until it bottoms out but be free to move up and down.