-

FREE MEMBER

NO Posting or PM's Allowed

bedding the ol H barrel? Plus a bedding material Q

Does anyone have experience or seen a barrel bedded H barrel in action? The stock profile benefited from stiffening exercises, someone must have tried it on an H barrel to see what would happen, any ideas?

I have a good original fulton smle here thats been bedded along 2/3rds the barrel with what looks like 1/16 or 3/32 cork sheet. The cork's also been surface treated with a silvery, very slippery, powdery/clumpy material that comes off on my fingers easily. Any ideas what clever old world substance that might be? I'd say graphite except for the color and texture, it stains the same and feels slippery the same.

thanks

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

08-30-2010 06:52 AM

# ADS

Friends and Sponsors

-

Advisory Panel

Does anyone have experience or seen a barrel bedded H barrel in action? The stock profile benefited from stiffening exercises, someone must have tried it on an H barrel to see what would happen, any ideas?

I have a good original fulton smle here thats been bedded along 2/3rds the barrel with what looks like 1/16 or 3/32 cork sheet. The cork's also been surface treated with a silvery, very slippery, powdery/clumpy material that comes off on my fingers easily. Any ideas what clever old world substance that might be? I'd say graphite except for the color and texture, it stains the same and feels slippery the same.

thanks

The silvery stuff will be graphite.

I've got factory bedded H barrel rifles (snipers), I've bedded a couple of H barrels myself using the some of the "old methods" described in the books by James Sweet (many dozens of hours). I have a fullbore rifle that was bedded in the thirties and is a proven competition rifle. I've even got a H barrel fully floated from an action mounted in an aluminium bedding block. Bottom line... Nothing beats a properly bedded barrel using the methods (refined) of factory bedding for a standard barrel. It can be very hit and miss, though. Another problem is, the woodwork can be unstable due to climate. A fully floated "H" barrel in good condition can be almost as accurate as the best bedded barrel, but more consistent. To fight this problem some old target shooters here used to hand make foreends and handguards from harder, older and dryer, therefore better suited more stable timbers. Use of cork or gasket paper packing was seen as the easy way out temporary fix or a method of getting a bit more life out of a buggered foreend. The cork was also infamous for eventually becoming compacted, hardening and cracking away.

The bedding starts at the butt socket. Just working under the barrel can just transfer the problem further back. The secret wasn't to try to lock everything up so it didn't move. It was to set it up so it moved exactly the same each time it was fired.

-

The Following 4 Members Say Thank You to Son For This Useful Post:

-

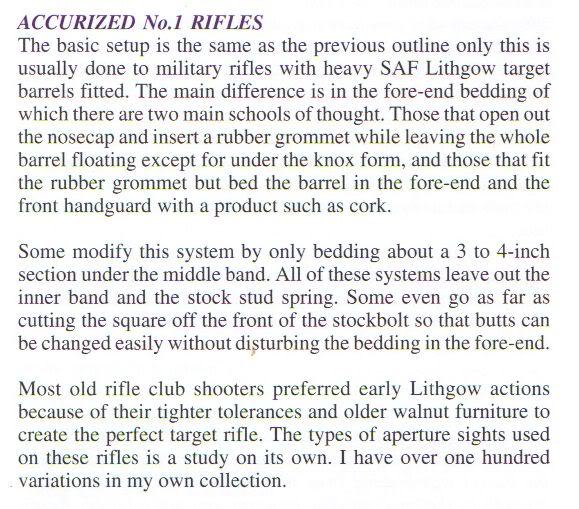

Most of the (heavy barreled SMLE)range rifles that I've seen that shoot well, are free from the knox to the centre band, then contact the forend to the muzzle with some form of packing under the front guard.

-

Thank You to tbonesmith For This Useful Post:

-

Advisory Panel

Most of the (heavy barreled SMLE)range rifles that I've seen that shoot well, are free from the knox to the centre band, then contact the forend to the muzzle with some form of packing under the front guard.

Thats the "factory" method modified (packing rather than take the time and effort to do it in the wood). Centre bedded (5 o'clock to 7 o'clock) at the knox, then the same for an inch either side of the inner band (which does not exist on the H barrel) and then at least four inches to the muzzle, with contact from the front handguard to match. There needs to be four to seven pounds lift to get the barrel off the bare foreend at the muzzle.

Here's a pic of factory bedding- marks left by the barrel

Last edited by Son; 08-30-2010 at 07:55 AM.

-

The Following 3 Members Say Thank You to Son For This Useful Post:

-

Banned

-

FREE MEMBER

NO Posting or PM's Allowed

Hi Son, Ed and tbonesmith , you've really well answered a bunch of questions thats been on my mind for months and months. In a probably rare moment of semi sanity I decided to wait as long as it took before I started accurizing my home spun target rifle properly. Your answers combined with a bit of a looky loo at fultons rifles in the last few months have completed the picture. There's an moa rifle in there somewhere, I just have to tease it out ...cheers and thanks R

, you've really well answered a bunch of questions thats been on my mind for months and months. In a probably rare moment of semi sanity I decided to wait as long as it took before I started accurizing my home spun target rifle properly. Your answers combined with a bit of a looky loo at fultons rifles in the last few months have completed the picture. There's an moa rifle in there somewhere, I just have to tease it out ...cheers and thanks R

FYI, the last time I got serious about an enfield last year, it was a 7.62 ishy, with a medium to decent bore. I sleeved it with an epoxy filled carbon fiber tube to stiffen the barrel, put a Canwest target trigger in it, and epoxy bedded the receiver and knox form, I also dowelled the fore end to trap the receiver the same way fultons rifles sometimes are. The end result was cloverleafs in nice tidy small bunches. I had to sell it onwards as one sometimes does, I hope to get it back soonish, I'll probably have to crowbar it out of the guys hands., but, that was an extraordinary shooter, and doubley satisfying being an ishy 308. This accurizing stuff really does work.

-

Legacy Member

Originally Posted by

Son

The silvery stuff will be graphite.

I've got factory bedded H barrel rifles (snipers), I've bedded a couple of H barrels myself using the some of the "old methods" described in the books by James Sweet (many dozens of hours). I have a fullbore rifle that was bedded in the thirties and is a proven competition rifle. I've even got a H barrel fully floated from an action mounted in an aluminium bedding block. Bottom line... Nothing beats a properly bedded barrel using the methods (refined) of factory bedding for a standard barrel. It can be very hit and miss, though. Another problem is, the woodwork can be unstable due to climate. A fully floated "H" barrel in good condition can be almost as accurate as the best bedded barrel, but more consistent. To fight this problem some old target shooters here used to hand make foreends and handguards from harder, older and dryer, therefore better suited more stable timbers. Use of cork or gasket paper packing was seen as the easy way out temporary fix or a method of getting a bit more life out of a buggered foreend. The cork was also infamous for eventually becoming compacted, hardening and cracking away.

The bedding starts at the butt socket. Just working under the barrel can just transfer the problem further back. The secret wasn't to try to lock everything up so it didn't move. It was to set it up so it moved exactly the same each time it was fired.

I am a Yank, and as such have far less experience than the regular user of these rifles but I would put forward a few comments on Son’s above analysis:

1) On the original H barrel SMLEs that I have examined in detail from the pre 1940 era (the barrels on the two examples I have seen were dated 1938 and 1939) the front nose cap was not relieved and the barrel bedding was such that the nose cap exerted some slight downward pressure on the barrel with the to upper “nubs” the bearing was equal on each of the nubs (the center area having a slight cut to eliminate barrel bearing. As the profile from the front sight forward is identical to that of the regular SMLE bedding, it was bedded the same as a standard SMLE, with the exception of the stud under the nose cap was missing and the middle band was also missing. This rifle shot quite well at 100 and 200 yards, with slight vertical stringing. That said it had a well worn but smooth barrel with a very stable walnut stock, which was stored inside a house in a temperate climate

2) In speaking to folks while at Malabar range back in February 2002 about some of their thoughts on the nose cap bearing. It was the general opinion of the few folks I spoke with that had extensive experience with the HB SMLE that with changing weather conditions the effect of a conventionally bearing nosecap would be detrimental the zero and accuracy of the SMLE, hence most all of the HB SMLE rifles in the pre 1960s competitive era had the nose cap cleared enough to allow the barrel to flex without hitting the nose cap. On the examples I saw, the clearance was enough to be perceived. This clearance allowed for both dry and wet days, as well as allowing for some slight stock warping. Were the nose cap to be fitted as in conventianl bedding, the barrel could become cramped as the stock swelled and warped with temperature and humidity. It is my understanding this was also true of the HB sniper rifle; they shot best when the barrel had no contact with the nosecap, though the nose cap hole was not enlarged on these rifles.

3) It was the opinion of both Fulton’s and AJ Parker that the SMLE front nose cap was a serious problem as regards the SMLE accuracy. In both of their regulation procedures the hole in the nose cap was opened up to avoid contact, with both the standard weight and after 1950 the heavy weight SMLE barrel. From my own limited testing, this seems to be a better method of setting up these rifles for accuracy. In any case when that is done, the nosecap no longer exerts any downward force on the front of the barrel, any such force being exerted by the upper handguard packing or in the case of the heavy barrel, the barrel itself. Since Fulton rifles were set up for Bisley conditions, with great variation in the humidity and hence stock swelling.

Based on the above I would venture to guess that Sons statement might not be quite correct under all weather conditions. The entire history of competitive shooting with the SMLE tends to indicate that relieving the nosecap bearing is worthwhile, though in the case of the standard weight barrel the downward tension then has to be applied by either cork (AJ Parker method) or spring bearings (Fulton method)

That said, I have not spent much time shooting the SMLE standard barrel or heavy barrel at long range, I would be interested in Sons reaction to my comments, especially if he is of the opinion that the conventional nosecap bearing is better in most cases. Not setting up for an argument, rather I am hoping to augment my “book learning’ what he has learned from experience.

-

Thank You to Frederick303 For This Useful Post:

-

FREE MEMBER

NO Posting or PM's Allowed

Thanks Frederic, that really helps me for when I get to the sharp end of accurizing the project,

I've pulled a pic of my fultons/parker hale, which has an obviously deliberate careful opening of that hole. I don't know who trimmed the barrel, it could have been the first owners, (navy) who had the facilities to do so. Its obvious someone considered this end of the rifle to be a very important part of it.

Another fultons had the entire nosecap as carefully bedded internally with an epoxy type mix as any receiver I've seen.

BTW, in the olden days, ok, golden days, what was used for bedding before epoxys arrived on the scene? (I know Eds answer already, a substance not in much evidence these days - elbow grease, as in very carefully fitted by a wood man with enough skills to shame a handful of wood choppers/boat builders)

Last edited by RJW NZ; 09-01-2010 at 03:51 AM.

-

Advisory Panel

Frederick, I haven't said anything about nosecap contact, I hadn't got into that sort of detail. The only part the nosecap plays in what I referred to as "refined standard bedding" is to hold the handguard on. The barrel is held firmly along at least the last four inches of the foreend to the muzzle, and the handguard trimmed (or packed) to provide a firm hold onto the top of the barrel. The bedding on the woodwork actually ends at the rear of the front sight block. Any contact forward of that can have an effect on the results.

My Lowmount HT shoots moa groups when it's in the right mood. If the groups are bigger, I do a quick check with a .002" feeler gauge to see if the nosecap is touching the barrel. If it is I loosen the screws and re-tighten them to ensure a gap all around the muzzle. That fixes it, I'm not going to bore the nosecap out on that rifle.

I have another H barrel target rifle that won't shoot without contact from the nosecap.

That is what I meant when I said "it can be hit and miss". There is no guarantee any one method will work on a particular rifle. Those blokes you spoke to could have experimented with and ruined dozens of new foreends to get the results they were after.

If you'd like an education from the old masters, I'd suggest you read James Sweet's book. It goes into detail about several methods... You'll see another popular method was called the "semi floater". Here the barrel has no contact with the foreend after the inner band recess until it goes through the front of the nosecap where some used a rubber ring tightly locating the barrel. This was also one of the so called "rubber nose" techniques. Others shot better semi floated with no "rubber nose". Some competitors would try every variation possible and use whatever gave them the best results. Others stuck to one method and battled on until it was as good as they could get it.

The barrel centering stud was an aid to dull the effects of moisture effected foreends by adding spring tension upward on the standard barrel. It does next to nothing. It was discarded for all heavy barrel work.

Another thing shooters did to lessen the effects of weather was to make foreends out of more seasoned harder timber. They also sealed the wood against the elements with all sorts of finishes and additives.

When you take all this into account, you get to where I was above "A fully floated "H" barrel in good condition can be almost as accurate as the best bedded barrel, but more consistent." The amount of work that a properly bedded barrel and action can take for the possibility of a negative result or only short term success that renders a good foreend useless, I will always recommend floating a barrel to everyone except the most diehard purists. There just isn't enough good foreends left to experiment with.

But, as the adds (and Ed) say, when everything else fails, there is always Mastercard!

Here's a pic of Malabar for you...

cheers,

Brad.

Last edited by Son; 09-01-2010 at 07:03 AM.

-

The Following 2 Members Say Thank You to Son For This Useful Post:

-

Originally Posted by

Son

Here's a pic of Malabar for you...

Let me know if you're heading out there any time soon, I'd love to catch you if are.

-

Register To Reply

Register To Reply