-

Banned

Hey Ed, those buckets full of .303 brass look strangely familiar although obviously allot cleaner. Thank God for the Lewis, Vickers and Bren, eh??

I'm sorry Brian the 500 Greek HXP cases I bought from you have already been cleaned, tumbled, weighed, bagged and boxed by case weight and year of manufacture.

The five gallon buckets of brass are "strangly familiar" because they are 5.56x45 mm NATO cases (.223 Remington) donated by our local Swat Teams who were too lazy to police up their brass at the range. The swat teams would line up abreast at the 50 yard line and walk aligned and in-mass to the target boards firing and reloading.

The Swat Teams ruined most of my shooting day as I "sadly" walked back and forth from the benches and the targets over and over again "policing up the littered shooting range. This happened so many times my gas mileage dropped off that month as I drove my truck home from the range with the rear end of my truck sagging and almost dragging the ground.

Sadly the last rifle I bought was a Stevens 200 in .223 and not an Enfield, my heart is broken at the sacrifices I must make for my shooting hobby.

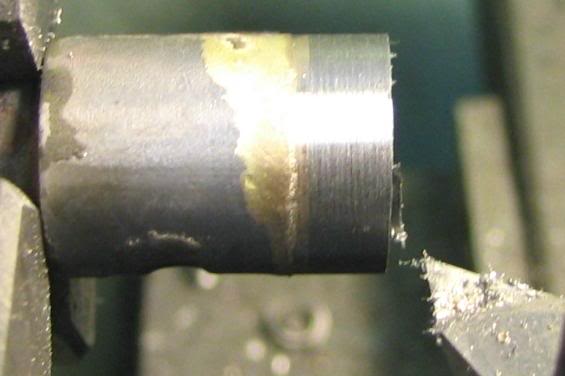

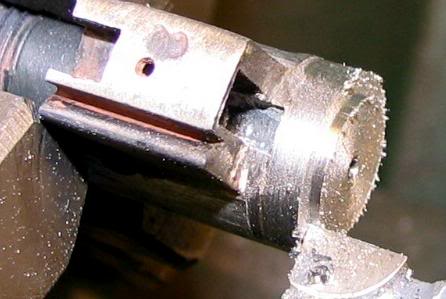

Did I tell you that you can adjust the headspace on the Stevens 200 by just loosening the barrel nut below.

-

09-16-2010 04:46 PM

# ADS

Friends and Sponsors

-

Legacy Member

Originally Posted by

Edward Horton

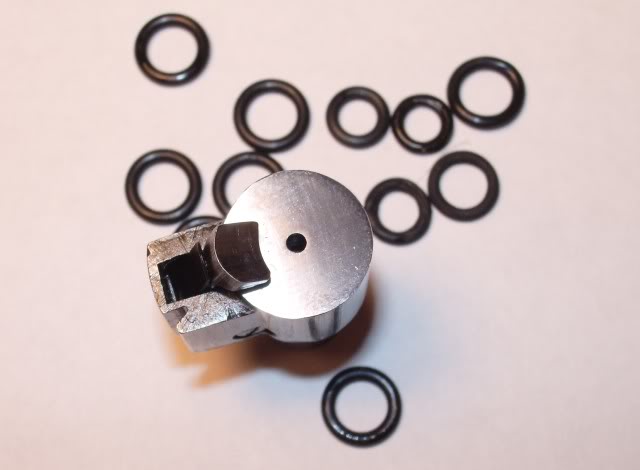

The last 100 cases I fire formed were with the same o-ring without any damage to the o-ring, your o-ring size will depend on your headspace setting, rim thickness and the diameter of your cases. I also remove the extractor when fire forming, the problem with American made cases is they tend to run to the smallish side on base diameter. When the o-ring is compressed and squeezed by the bolt it centers the cartridge in the chamber, and helps promote equal case expansion.

While this is getting well beyond the original question, there are different routes to the same destination.

I've never heard of "the o-ring method" before.

On the other hand, what I have always done with new .303 brass is use M-dies to set up a false shoulder on the brass before loading that results in just being able to get a crush fit when closing the bolt. With this method, there is not much question that the brass is firmly supported between the shoulder of the chamber and the face of the bolt, and any movement of brass is going to be outward only.

I am also anal enough that I wrap thin strips of masking tape around the base of the brass (having determined how many wraps are required) which allow it to just be chambered before first firing. This generally takes place during commercials while watching the military channel or whatever on TV. The idea of this is to ensure that if the false shoulder doesn't center the case within the chamber, the tape certainly makes sure it does.

I keep a good thing going by using Lee's collet dies for resizing so the brass gets worked no more than necessary.

I don't know about others, but this certainly works for me.

For better or for worse, using this to set up brass for all future loading, results in brass that has long life and accuracy out of my two LE's that I certainly can't snivel about. I buy all my brass in lots of 500, so it is a relatively infrequent chore which I consider to be acceptable in exchange for what I think it delivers in ease of reloading and case life.

With all of that in mind, the o-ring idea is now busily racing around in my mind. It seems to me that this would replace the irritant of wrapping tape ahead of the rim quite nicely while ensuring the base of the case was centered in the chamber at the back.

This bears investigation. What size o-rings do I head out and search for?

-

-

-

Banned

-

Legacy Member

Originally Posted by

Edward Horton

Optimist over at Gunboards did a destruction test with new Remington cases after I posted the o-ring method of fire forming there. Optimist reached 32 case reloading number before the first case failure and had NO case head separations.

Well, it sounds like we're taking somewhat similar paths to the same results. O-rings, obviously, are a lot faster way of centering the brass up in the chamber than wraps of masking tape. However, I'll continue putting a false shoulder on each new piece of brass prior to first firing, even though I see no mention of him doing that. The false shoulder ensures there is hard contact at both the shell base and shell shoulder - something the o-ring won't do. Whether hard contact versus o-ring will make any difference, I don't know and am too lazy to investigate. But putting the false shoulder there takes no time at all, so I'll continue with that. I do like the idea of no more tape wrapping, however, for centering the brass.

Your o-ring size for fire forming will depend on the case base diameter and your headspace setting, I use three different sizes depending on the Enfield used.

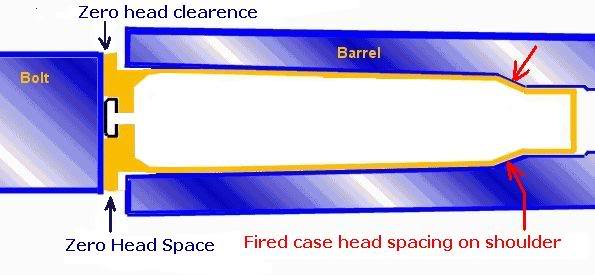

I even lapped a zero bolt head to give me a headspace setting of over .084 and used the o-ring method with no ill affects. I like having tight headspace but the o-ring method makes the word "headspace" meaningless (within reason) on the

Enfield Rifle

.

Hmmmm... well, there's no "headspace slop" (for lack of a better term) once you put a false shoulder on the case that just barely allows the bolt to close. I suppose when I try it I might want to start on the smaller sizes, because with a false shoulder the o-ring is more about centering the case than keeping the base back against the bolt head. And my LE's are nicely minty with "0" bolt heads, so there isn't a lot of extra room in there to begin with.

-

-

FREE MEMBER

NO Posting or PM's Allowed

damn, this thread was fun. can someone point me where to go to learn about the pupose and use of this o-ring procedure? please

-

Banned

-

Advisory Panel

Thanks for the tutorial on your O-ring method, Ed.

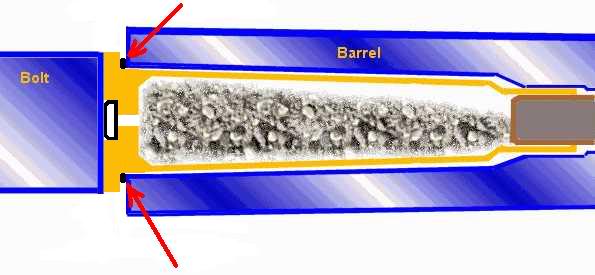

I have been shooting Lee-Enfields for more than 40 years myself and I really get tired of people telling me about those weak old actions which murder brass. The separating brass is caused, inevitably, by case stretch. With Ed's method, you reduce firing stretch to nil just as long as your pressures are sane.

The OTHER cause of case stretch is the expander ball of your reloading dies. The sizing die sizes the casing back down to below minimum size and then, when you lower the case on your press, the expander ball drags back through the neck, stretching it. I have found that some dies actually produce MORE stretch at the neck, from a single firing, than you will get at the back end from an ill-fitting casing. This happens EVEN if you are neck-sizing only, as you should be doing for brass which now is fitted precisely to YOUR chamber. Of course, when you use one of these over-length cases, it pinches the bullet in place because it is much too long, pressure spikes, you get a flyer at the target and, if your case is anything except perfect at the back end, it nips off because the increased pressure has made your action 'spring'. You can reduce THIS cause of case separations very nearly to zero just by lubricating the insides of your case necks before sizing them.

You now have .303 brass that will last just as long as any other calibre, given that you are not running absolute barn-burner loads. LEE Collet Dies are a great help on reloading for long life with your brass, but combining Ed's O-rings with the collet dies, or combining the O-ring method with lubing the insides of the necks before neck-sizing, will give you brass which will last much longer than you thought possible.

Have fun!

-

Thank You to smellie For This Useful Post:

-

FREE MEMBER

NO Posting or PM's Allowed

geez, I've been reloading .303 for almost but not yet two years now and I've used the fire forming and Lee collet in my excercise and have gone from 2-3" groups at 100 yards using commercial factory store bought stuff but after practicing FFing and neck sizing my groups have decreased to 1.5" at the most. Now seeing how there is no "hour glass" done to the case and the o-ring centers the system, I am a little anxious to see my results using these methods. Thank you very much gentlemen!!!

-

Banned

-

Legacy Member

Originally Posted by

Edward Horton

no4mk1shooter

On a non-rimmed cartridge case like the .308 being fire formed for the longer chamber of the 7.62 NATO you had two choices.

1. When reloading you would seat your bullet "long" so it would touch the rifling and hold the case against the bolt face.

2. Make a false shoulder on the case neck or enlarging the neck of the case so it held the case against the bolt face.

Now here are some problems with the two methods of fire forming I listed above.

1. On the majority of used

Enfield Rifles

, the throat is too long and you can not seat bullets out long enough to touch the rifling.

2. Creating a false shoulder can lead to and cause cracked necks due to the amount the necks are enlarged. (over working the brass)

Ed, can you relate your experiences where creating a false shoulder one time to create brass that is both centered in the chamber and properly sized after firing led to the cracked necks you are talking about?

I have been creating false shoulders on .303 brass for years, stretching back to well before the WWW ever existed. Read George Nonte originally describing the technique, if memory serves me correctly.

I can't recall every having cracked necks as a result of using the false shoulder technique, nor can I recall George Nonte ever writing of similar problems - granted, he has been gone from the range for some time now.

I am curious that you experienced cracked case necks after creating a false shoulder while I haven't, and wonder what you might be doing differently than me that I want to make sure I stay away from.

I intend to use the o-ring method the next time I do some brass in lieu of the tape method at the rear in conjunction with a false shoulder. I am not sure that an o-ring guarantees a case centered in the chamber in addition to keeping the base of the case against the bolt head. I am also not sure that the majority of rifles would actually show a difference one way or the other, however.

If I had some spare time, I would buy a few hundred new cases and explore the differences between all three, because I do have a pretty accurate No. 4 to play around with.

-

Register To Reply

Register To Reply

and they had not even invented brass cartridge cases or rubber o-rings yet.

and they had not even invented brass cartridge cases or rubber o-rings yet.