-

FREE MEMBER

NO Posting or PM's Allowed

Swedish Mauser reloads key-holing!?

Swedish Mauser reloads key-holing!?

-

09-29-2010 08:41 PM

# ADS

Friends and Sponsors

-

Advisory Panel

The usual 6.5x55 military throat, designed for the long round-nose original bullet of 1894 or so, has a long "freebore" before the lands begin. The diameter of this freebored section is normally ~.268". If bullets are not dimensioned to fit this unrifled part of the barrel, they can yaw before being engraved by the lands. With jacketed bullets, this isn't often a problem - the stiff jacket offers enough resistance to allow the lands to steer the yawing bullet back on a straight path. But with relatively softer cast lead alloy, the yawing bullet can engrave off-axis and isn't stiff enough to be straightened out by the lands. The result is a bullet that leaves the barrel with a serious case of instability. "Keyholes" at the target are a symptom of gross instability.

The prime remedy for this situation is to use cast bullets that are sized to fit the throat and seat them as far out as possible, minimizing the unsupported jump before they engage the lands. Using a harder alloy can also help, but not as much as using the right size - even pure linotype is nowhere near as stiff as a copper-alloy jacket.

Sometimes changing to a slower powder can help. Trail Boss is a pretty fast powder and gives the bullet a swift kick in the tail. The more gradual shove of something like 4759 or 5744 might prove better - or not, especially with undersize bullets.

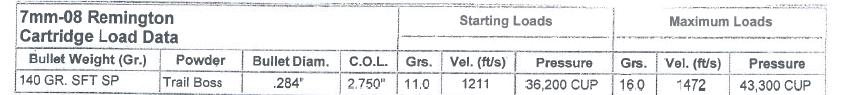

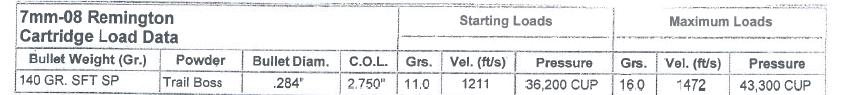

It's also possible your load is running considerably more pressure than we normally expect a cast bullet to stand without getting all wobbly on its way out the barrel. Although I can't find any pressure-tested data for the 6.5x55, Hodgdon does list a load for the 7mm-08, a cartridge reasonably similar in capacity and bore size to the 6.5x55 -

If your 13.5-grain load is giving the same kind of peak pressure as even the 11-grain starting load shown here, it's probably a bit much for optimum cast bullet performance.

-

The Following 2 Members Say Thank You to Parashooter For This Useful Post:

-

Advisory Panel

Parashooter has explained it perfectly!

I had similar probems in another caliber, and came to the same conclusion. Trail Boss is a powder that is made to be bulkier than typical smokeless powders, to achieve better case filling. But regardless of the form factor, it is a very fast smokeless powder with a burn rate that I would never dream of using in a Swedish Mauser in normal granulation. The GSC burn rate table shows it as being in the same region as Hodgdon Clays or Vihtavuori N320. Not the thing for a barrel with the extreme length/bore relationship of a Swedish Mauser. Loading recommendations for cast bullets available here typically specify N110 - similar to the 5744 recommended by Parashooter. I and several friends have used N110 with success in reduced loads, but Trail Boss was a disappointment.

Mauser in normal granulation. The GSC burn rate table shows it as being in the same region as Hodgdon Clays or Vihtavuori N320. Not the thing for a barrel with the extreme length/bore relationship of a Swedish Mauser. Loading recommendations for cast bullets available here typically specify N110 - similar to the 5744 recommended by Parashooter. I and several friends have used N110 with success in reduced loads, but Trail Boss was a disappointment.

Patrick

-

-

FREE MEMBER

NO Posting or PM's Allowed

-

Contributing Member

I don´t like the cast bullets out of the rifle. We are using the Sierra MK-bullets with the N110 and having great results in accuracy.

Regards

Ulrich

Regards Ulrich

Nothing is impossible until you've tried it !

-

-

Banned

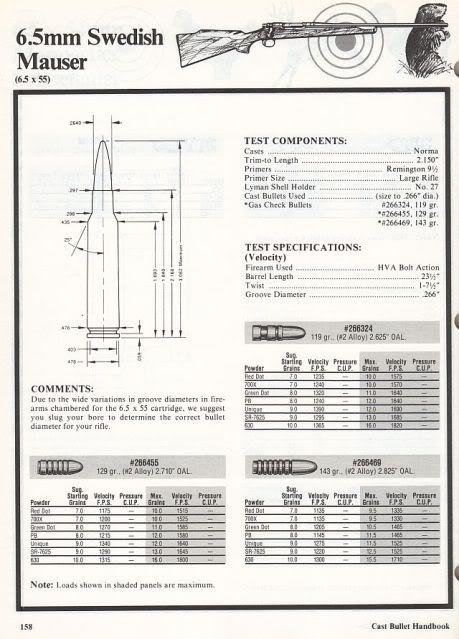

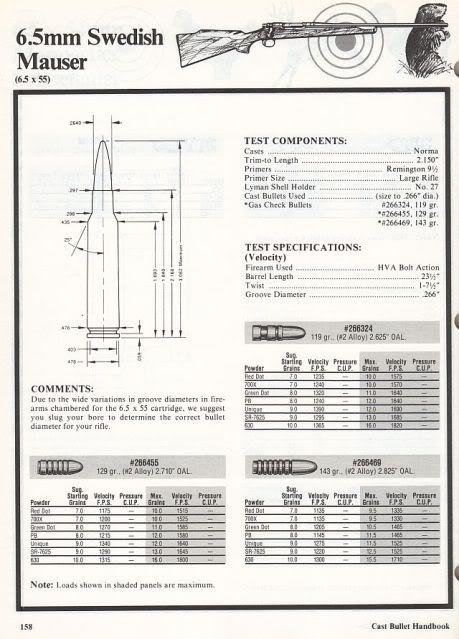

If you look at the load data below Trail Boss burning rate is between Green dot and PB, so your Trail Boss load is on the "warm" to "HOT" side for your cast bullet loads.

Sorry for the small print below, loads below are for both the 119gr and 143 gr bullets

Green Dot starting load 8.0 grs and 11 grs max

PB starting load 8.0 grs and 11.5 max

Below, reduced loads with SR-4759

Two other things to check.

1. The gas check and base of your bullets might be off or crooked causing the bullets to yaw as soon as they leave the barrel.

2. Your cast bullets look to be the same constant diameter (base diameter and nose diameter) The majority of good shooting cast bullets I have used in the past had two diameters, the nose was sized to ride the lands and the base was sized to ride the grooves.

Example: a cast bullet for a 30-30 Win

Base diameter .308

Nose diameter .300

The nose of the above would ride on top of the lands and the base would fill the grooves.

-

Advisory Panel

What is the major diameter of your bullets? What is the diameter of the nose section ahead of the forward (unlubed) groove? What is your rifle's groove diameter? Throat diameter? Without knowing these critical dimensions, we can't give much specific advice other than to try a much lighter load (about 8 or 9 grains of Trail Boss) in the hope that lower pressure and velocity will alleviate the deformation that's causing instability.

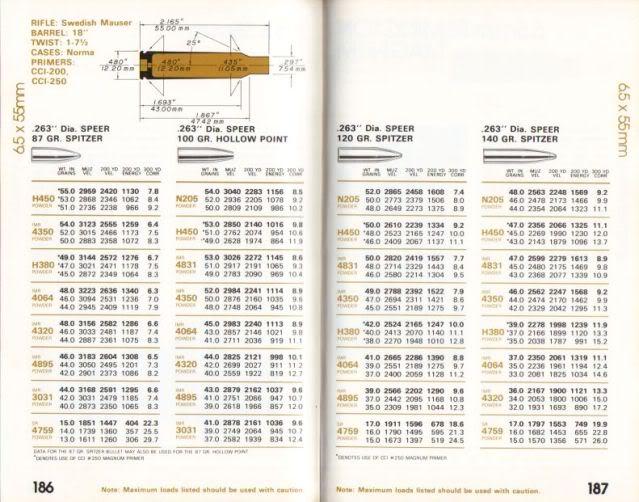

To give you an idea of the bullet configuration for which these rifles are throated, here's an example of a 6.5 round with the original-style bullet -

As you may see, the bullet is very long and its ogive short. This requires an extended freebore to allow chambering.

-

-

Advisory Panel

Parashooter has posted an excellent photo of the kind of bullet that performs well in most old service rifles. I have just about given up trying to use lead bullets with nitro powders. The results have been keyholing, leading, and just plain lousy grouping. But the long type of bullet with short ogive gives the best lead into the rifling with chambers and throats that are often overlong by modern standards. Please do not forget, we are talking in many (most?) cases about rifles that were built long before the CIP/SAAMI standards were derived.

The OAL should not be taken from a book, but adjusted to suit the individual rifle. If you want to achieve best results for target shooting, you may well need an OAL that is too long for magazine loading. Take a bullet and make the following simple test:

1) Close the bolt on an empty chamber and insert a 6mm /1/4" rod into the barrel, let it down until it rests on the bolt face. Make a mark on the rod at the height of the muzzle.

If you wish to be more precise, use a threaded rod with a nut + lock nut to mark the level. Using a 6mm rod with 1mm pitch I can, in this way, make measurements of head clearance that are quite sufficient to judge whether an old rifle is usable or not. Especially since all my rifles use neck-sized cases that are reserved for the individual rifle.

2) Now remove the bolt and insert a sample bullet into the chamber. Use another rod to push the buller into the throat. As the bullet enters the throat it will push out the rod with marking (or locked nuts). Continue until the bullet just touches the lands. It takes a touch of practice to develop a sensitive feel and achieve repeatable results.

If you now measure the amount by which the marking (or locked nuts) have been pushed out, you have a simple measurement of the maximum overall length that can be used to just contact the lands with THAT bullet in THAT rifle.

In many cases, you will be surprised, even shocked at the result. For my Arisaka , Carcano and Argentine

, Carcano and Argentine Mauser I now know that a boattail bullet would be well out of the cartridge case before touching the lands.

Mauser I now know that a boattail bullet would be well out of the cartridge case before touching the lands.

To avoid the yawing and resultant bad shooting already explained by parashooter, the bullet must make contact with the lands before it is fully free of the case neck. That rules out boat tails in some cases. And in other cases, the amount that would be left in the neck would not suffice for secure seating.

As a pragmatic rule: take the OAL measurement as described above. Reduce that by about 20 thou / 0.5mm for non-critical seating. Have you still got enough to seat the bullet in the neck? Can you still load the round in the magazine? You may have to make a compromise.

Finally, a word about bullet diameter. From what Parashooter wrote, it might appear reasonable to take the thickest cast lead bullet that will fit, in order to fill the non-rifled section of the throat as well as possible. But this may be so fat that it becomes impossible to seat the bullet in a normal seating die, or the loaded cartridge may be so thick in the neck that it cannot be chambered. That is exactly what happens with the Argentine Mauser.

For all the "problem types" mentioned above, my only solution to date has been to use the long Hornady round-nose/flat-base bullets, which are the closest I can find to the original profiles. None of these rifles has performed satisfactorily with any combination using lead bullets.

Patrick

Last edited by Patrick Chadwick; 10-01-2010 at 06:52 AM.

-

-

FREE MEMBER

NO Posting or PM's Allowed

Excellent info guys!

Excellent info guys!

Thanks for hanging in there with me on this one. I'm definitely learning as I go. Thanks too for the photo of an original cartridge.....very helpful (and I thought I was launching a torpedo!) I'll report back after I've had a chance to digest some of your info!

Thanks for hanging in there with me on this one. I'm definitely learning as I go. Thanks too for the photo of an original cartridge.....very helpful (and I thought I was launching a torpedo!) I'll report back after I've had a chance to digest some of your info!

Happy Shooting!

-

Advisory Panel

aprayinbear, just two observations about your lead bullets:

1) in your 2nd pic, I think I can see a size reduction about halfway between the first and second grooves. You could check that with a micrometer or good slide gauge. So maybe your bullet is intended to be nose-riding.

2) But why is the first groove empty? What is it for, if not to hold lubricant? How about getting some lube into that groove?

Patrick

Last edited by Patrick Chadwick; 10-01-2010 at 03:05 PM.

-

What Gives?

Information

Information

Register To Reply

Register To Reply

Or am I way off base?

Or am I way off base?

Thanks for hanging in there with me on this one. I'm definitely learning as I go. Thanks too for the photo of an original cartridge.....very helpful (and I thought I was launching a torpedo!) I'll report back after I've had a chance to digest some of your info!

Thanks for hanging in there with me on this one. I'm definitely learning as I go. Thanks too for the photo of an original cartridge.....very helpful (and I thought I was launching a torpedo!) I'll report back after I've had a chance to digest some of your info!