-

Legacy Member

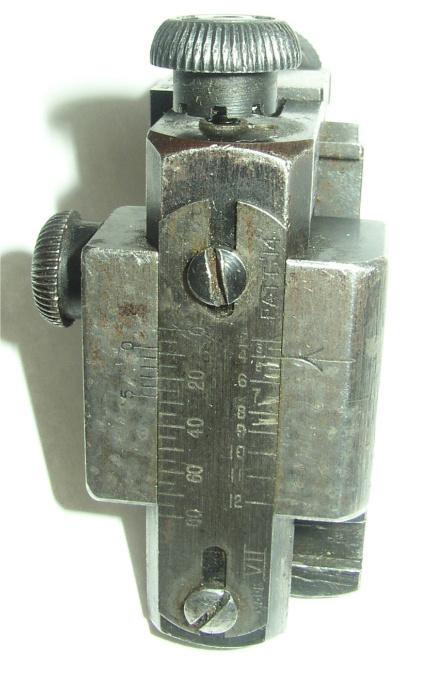

Parker Hale sight repair

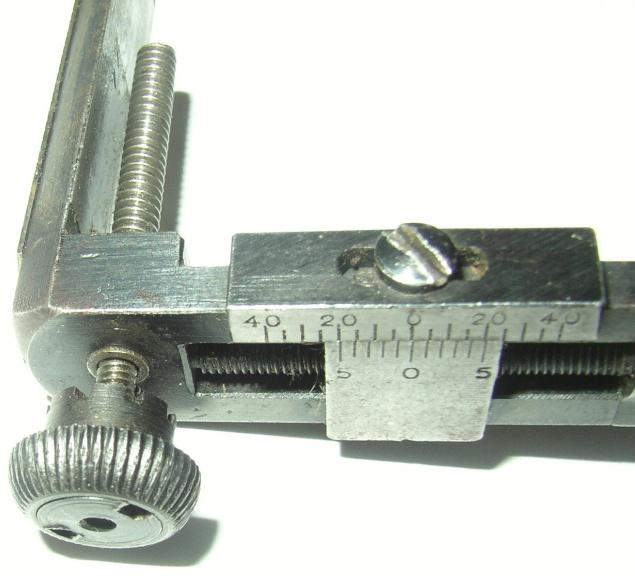

I've got a Parker Hale 5B that is not working. The windage works perfectly, but the elevation does not.

Is there anyone out there who reparis Parker Hale sights?

Thanks

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

-

04-20-2011 07:45 PM

# ADS

Friends and Sponsors

-

FREE MEMBER

NO Posting or PM's Allowed

pm me if u like, I do most things, NZ located. RJW

located. RJW

-

-

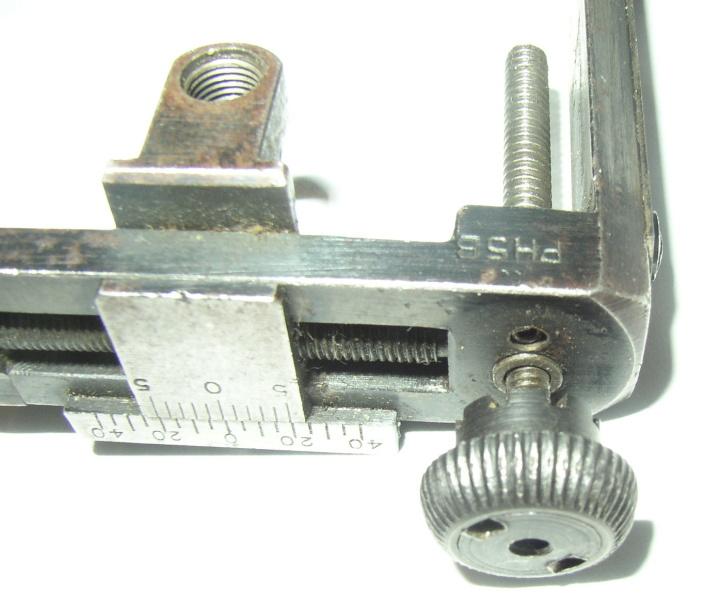

Fultons have most of the spares stocks from P-H for their sights RJW. But, alas, not all of the bits! And after having had a few of them pass through my hands, I can confirm that there were MANY, many variables of each sight............. Standardisation wasn't their strong point

-

-

Legacy Member

You're best to find somebody within your country of residences to do the work. It will save you considerably on shipping and any imposed duty on entry/exit.

What is wrong with your sight? If the elevation lead screw is damaged you are looking at a costly repair. Parts need to be hand fitted as no two are alike. I'd look at buying a good rebuilt sight and using this one as a trade-in. Most guys rebuilding with take a damaged sight for parts.

Hope this helps,

Ron

-

-

FREE MEMBER

NO Posting or PM's Allowed

I have a complete working 5b top arm here if you want to buy it and just do a straight install, that'd be the easiest way if you're not handy.

-

Legacy Member

Thanks for all the replies.

I guess the thing to do is pull it apart and see if I can determine why it doesn't work.

I'll do that and post the results.

I emailed Fulton's of Bisley, but have not yet received a reply.

RJW, I'll get in touch after I have disassembled the 5B

-

-

Don't be put off shipping it Calfed. I've just sent two rebuilt sights abroad and jiffybag postage with the correct declaration as a 50 year old repaired sight was £4.

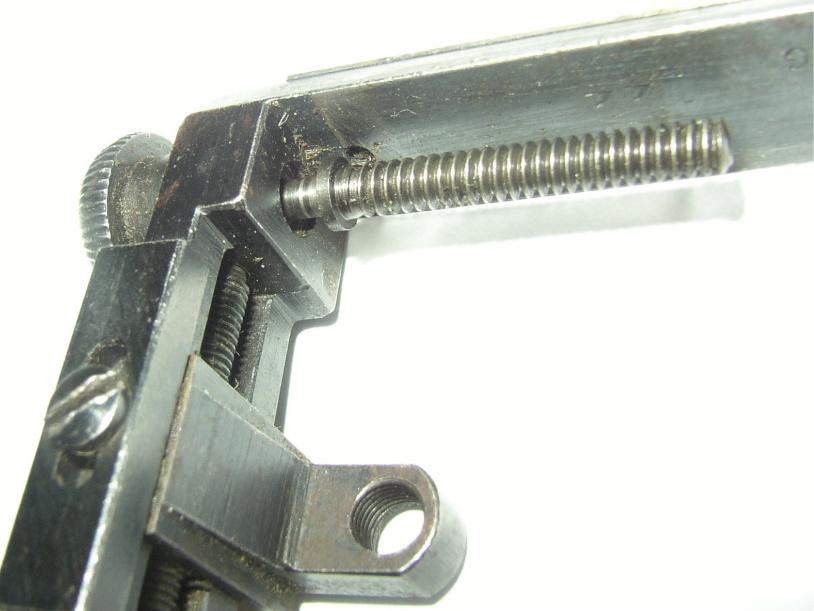

But DO NOT mix bases and slides unless you have some good calibrating/inspecting facilities. That's only my very recent experience. The main problem with the elevating mechanism jambing up us a bent top to the leadscrew that causes the knob to foul the arm and .............

Have a go yourself first but might I suggest you undo it inside a polythene bag so that when the springs and balls fly out, which they certainly will the first time....., you'll still have them.

-

-

Legacy Member

-

-

Legacy Member

-

-

Legacy Member

From memory

Unscrew the cap in the top of the elevation screw head and you will see how the whole thing works.

You need a small ball bearing and tiny spring for the clicking mechanism and the cap screws to the top of the elevation threaded shaft - and you should be good to go.

I'm sure the forumers will come up with the bits.

Apologies to the Armourers for descriptive terms - I'm just a gunner.

John

-

PM

PM