-

Legacy Member

Barrel washers/shims

Although tech details mention barrel shims in two sizes (.002 & .003) I have only ever found

.002 barrel shims.

Am I just unlucky or were the .003 shims done away with to only allow a maximum of two

.002 shims ?

Anyone got any .003 shims ?

ATB Kevin

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

-

08-29-2011 08:01 PM

# ADS

Friends and Sponsors

-

We've got .003" shims and they were available. You could use up to .005" but unlimited (within reason of course) on DP guns as I recall. However, the use of shims on 7.62mm barrels was not permitted EXCEPT for the L55 DP guns

The shim 'top hat' tool is interesting because we had to make one of those during the sheet metalwork phase of our apprenticeship. Mine was rubbish of course, looking like a ring doughnut!

-

-

Legacy Member

Hello:

Now I know what that was that I peeled off of a barrel shank... Is there an already composed pargraph or two on why such an item was used and how its required use was identified? Is it purely a headspace tool or did it have to do with the barrel nut engagement? Other?

I'm all ears!

-

-

The shims were used so that you could get an exact fit with two barrels on the same gun using the same barrel nut. Because no two barrels were the same for example, we'd have to replace one shot-out barrel with another part worn barrel (we tried to keep matching barrels with matching worn bores or certainly within what we'd call 'quarters of life'). If the good barel was nice and tight, we'd fit a similarly worn replacement barrel. If this was slightly loose, then you could use a .002 or .003" shim - up to a total of .005" - to tighten up the second barrel. This COULD open up the CHS so you'd have to start again but generally speaking you could easily bring in both barrels to get the correct tightness and CHS.

Another thing. OFFICIALLY the second barrel had a letter 'S' stamped after the serial number and was kept in the holdall (the big long barrel bag.....) but once we were in the big bad REAL world, we were told NOT to mark the second barrel with an 'S' so that both barrels were used equally.

So if you have an old barrel with a letter S after the serial number, that's the reason why

Last edited by Peter Laidler; 08-31-2011 at 01:39 PM.

Reason: speeeling misteak

-

Thank You to Peter Laidler For This Useful Post:

-

Legacy Member

Cheers Peter,good to know they are out there somewhere

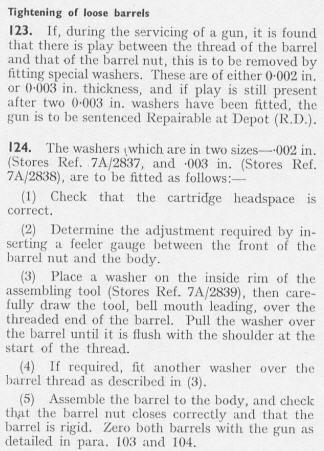

WallyG, an extract from AP1641 -

ATB Kevin

-

Thank You to Kev G For This Useful Post:

-

Yep, that's the RAF instruction. We went to .005"

-

-

Legacy Member

Yep, that's the RAF instruction. We went to .005"

Yes I have noted the difference in maximum tolerances between services Peter.......but why ?

ATB Kevin

-

-

I would imagine that it's because the RAF Brens didn't get the pounding that the Army ones got so they could relax their spec slightly. They didn't have the quantity of Armourers that we have and as a result, most of the time any repairs beyond the station 'bomb jockeys' (as RAF Armourers were called.....), the weapons had to be back loaded to a main repair depot. After the late 70's or so, after the RAF equivalent of unit repairs came under the wing of the Army so our rules counted

-

-

Legacy Member

Thats a new one Peter, never been called a bomb jockey, i've been called a bomb 'ead and a plumber before. I'll have to remember that one!

-

-

Well........, I'll be blowed. Didn't know that you were a bomb jockey BP. If I'd known, I'd have laid it on a bit thicker!

What's that aeroplane? They all look the same to me. I suppose your Summer Holidays will be ending soon. Keep safe

-

PM

PM