-

Advisory Panel

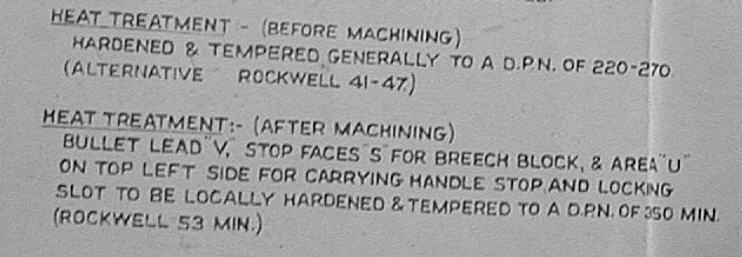

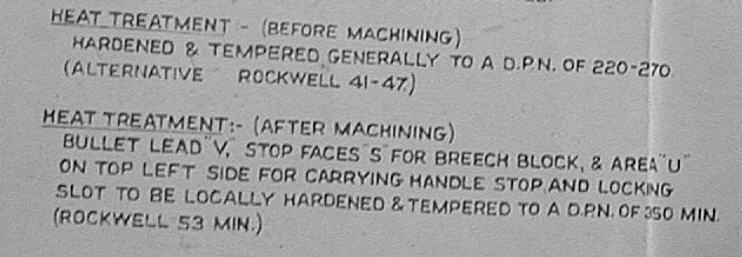

Heat treatment of Bren receiver

Chinese Brens photo - mrclark photos at pbase.com

Now is that a spot anneal or an induction hardening spot?

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

Thank You to Lee Enfield For This Useful Post:

-

02-07-2012 01:10 PM

# ADS

Friends and Sponsors

-

If you are referring to the black elongated mark on the gun bodies in the photos then to be honest, I dispute that it IS an annealing or an induction hardening mark because on that part of the body, what is there to harden? The only part I can think of is to mallurgically normalise the many edges around the front opening of the magazine well OR to harden the feed ramps into the chamber. But hardly, because the suft copper projectiles wouldn't wear anything out in any case. What about the barrelopening. Not that either as the discolouration doesn't extend there either and in any case, they regularly used to wear out and be replaced at Base workshops

Nope............. no idea. It's definately an induction process because the black staining is visible internally through the other side of the body

-

-

The strange thing is that while there is a heat treatment mark of some sort on the front of the gun body, there isn't a heat treatment mark at the cocking handle ramp (at the front of the Mk2 type cocking handle slot) which IS hardened to prevent friction wear.

Anyone else got any comments........ or am I missing something in L-E's original question

-

-

Advisory Panel

The strange thing is that while there is a heat treatment mark of some sort on the front of the gun body, there isn't a heat treatment mark at the cocking handle ramp (at the front of the Mk2 type cocking handle slot) which IS hardened to prevent friction wear.

Anyone else got any comments........ or am I missing something in L-E's original question

You are right, that is exactly my question, the only things I could think is induction hardening the feedlips, mag locking recess, bullet guide, or where the front bolt body locks.

I really cannot think of a reason to anneal the receiver in that area??

-

-

You've answered your own question there LE. It's to induction harden the front face of the breech block stops. The breech block doesn't lock anywhere near there. It lock up at the rear into the locking shoulder but it certainly comes to a STOP there and if there is no cartridge in the chamber, then the block stops against the breech block stops with some considerable force. If it didn't, it'd beat against the barrel face.

-

-

Legacy Member

ATB KG

-

PM

PM