To take a bolt apart you need to be watching for a bolt tool in auctions. Most guys with one or two carbines won't need an extra pawl, the tool is not used that much and should be OK. It's the guy who takes a lot of bolts apart that come accross this issue and might need an extra pawl lying around.

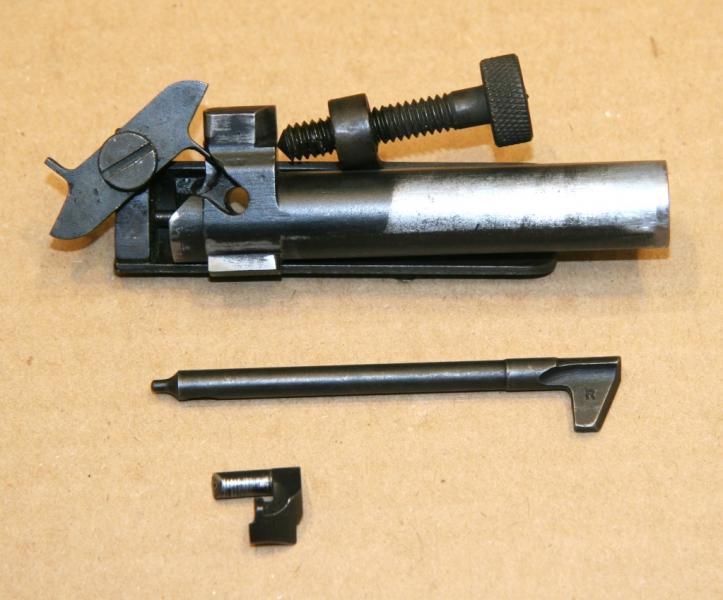

The Pawl is the part of the bolt tool that swivels, shown on the left side.

The bolt goes into the tool with pin you see against the ejector.

Swivel the pawl into place on the extractor plunger. You notice the plunger has a ledge cut into it.

Tighten the thumb screw and the pawl compresses the extractor spring and pushes the extractor plunger out of the way.

Then you can push the extractor out from the back side and pull out the firing pin.

Assembly in just the reverse.

Now if you want to remove the spring and plunger you release the thumb screw while the extractor and firing pin are out. Do this slowly as the plunger likes to go flying. Some place it in a baggie. Inspect, clean, lube, whatever. Then you need to put it back together. Not hard, but can be tricky. The split end on the pawl holds the plunger because of the ledge in the position you want for reassembly. Over time and use, or just tightening too hard the split end of the pawl breaks off. Everyone does it. Everyone gets upset about it because the darn pawls are hard to find.

That was the reason for the post.

Jim

Information

Information

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current.

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

Register To Reply

Register To Reply