-

FREE MEMBER

NO Posting or PM's Allowed

How do I fix 1903-a3 peep that moves sideways?

I've had a Remington 1903-a3 in the safe for over a decade and just recently got it out for the first time. It shot a 2" H x 4" W 10 shot group off of bags at 100 yards using Federal 150g softpoint ammo.

I notice the peep slider has a lot of side to side play. How do I fix that? I've got more questions but I'm going to look around this wonderful site to see if I can find answers.

Thanks,

Szumi

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

Last edited by Szumi; 08-23-2012 at 07:02 PM.

-

08-23-2012 06:59 PM

# ADS

Friends and Sponsors

-

Legacy Member

Welcome.

Just to be clear.... is just the small peep slider moving side to side or the whole assemby that has the windage screw going thru it? Is the windage screw moving left and right too? Or is the entire rear sight assembly moving Left and Right on the receiver dovetail?

-

-

-

FREE MEMBER

NO Posting or PM's Allowed

The only thing that has slop in it is the peep.

-

Legacy Member

All the following is presuming that there is no other damage to the peep or the ramp:

You will notice that the peep is guided by the slots in the ramp and in order for the elevation adjustment to work there must be clearance in the components. Depending on how each part was manufactured the clearance will range from very little to quite a bit. You will also notice that the peep has a sheet metal spring that detents into the elevation adjustments. Generally a good firm spring will hold the peep in place pretty well both vertically and horizontally. Certianly well enought for the original purpose and well enough for fun shooting. You can try getting a few springs and seeing if they make enough difference for your needs.

On my rifles that I set up for matches, I will remove the peep from the ramp and use a small punch to peen the legs that mate with the ramp slot until it will stop sliding in the ramp. Then I use a fine stone to touch up the peened area until the peep slides in the ramp, but without lateral play.

Other folks may offer up some other solutions too. Good luck!

-

-

FREE MEMBER

NO Posting or PM's Allowed

Peen+blue loctite works for me

-

FREE MEMBER

NO Posting or PM's Allowed

Originally Posted by

Allen Humphrey

All the following is presuming that there is no other damage to the peep or the ramp:

You will notice that the peep is guided by the slots in the ramp and in order for the elevation adjustment to work there must be clearance in the components. Depending on how each part was manufactured the clearance will range from very little to quite a bit. You will also notice that the peep has a sheet metal spring that detents into the elevation adjustments. Generally a good firm spring will hold the peep in place pretty well both vertically and horizontally. Certianly well enought for the original purpose and well enough for fun shooting. You can try getting a few springs and seeing if they make enough difference for your needs.

On my rifles that I set up for matches, I will remove the peep from the ramp and use a small punch to peen the legs that mate with the ramp slot until it will stop sliding in the ramp. Then I use a fine stone to touch up the peened area until the peep slides in the ramp, but without lateral play.

Other folks may offer up some other solutions too. Good luck!

Okay, I unscrewed the little screw that holds the sheet metal spring and it looks like the slider thing has 0.014" of side play measured at the peep. That equals about 1.9" of wind age variability at 100 yards if I didn't flunk the math test. That would help get my grouping closer to round.

When you say peen the leg, the peep slider looks like it has a dado cut on both sides, so there are two surfaces that could be peened, are referring to the widest pair? Is 0.007" upset per sideby peening achievable?

Thanks,

Szumi

Last edited by Szumi; 08-24-2012 at 05:01 PM.

-

Legacy Member

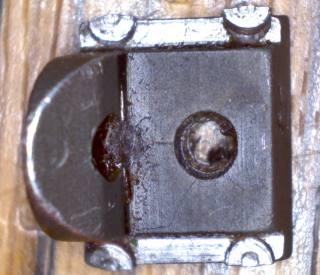

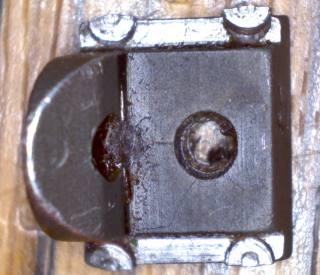

Attachment 36316Attachment 36316

I usually just bump the four corners and then dress them up to a perfect fit with the ramp slots.

not sure how I got 2 pictures oh well

-

-

FREE MEMBER

NO Posting or PM's Allowed

Originally Posted by

Allen Humphrey

I usually just bump the four corners and then dress them up to a perfect fit with the ramp slots.

From the top, I didn't consider that.

Thank you very much Allen.

Szumi

-

FREE MEMBER

NO Posting or PM's Allowed

Even with a 4 oz hammer I hit it too hard.

I have it dressed now and it fits.

Thanks again,

Szumi

Register To Reply

Register To Reply