-

No4 T with a difference....

Although the deal was made many moons ago, managed to pick it up yesterday from another forum member, had to kill some time first and have been meaning to drop in to IWM Duxford, seems like I arrived on the correct day and had an excellent greeting from the sound of a Rolls Royce Merlin engine and display from a Spitfire, also a P51 Mustang.... More about these in the off topic forum and more pics,

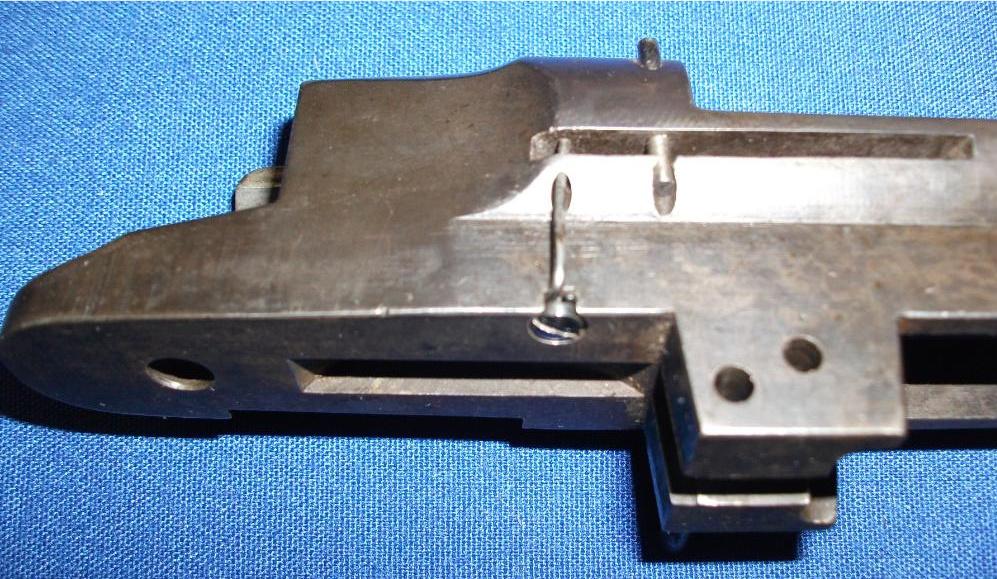

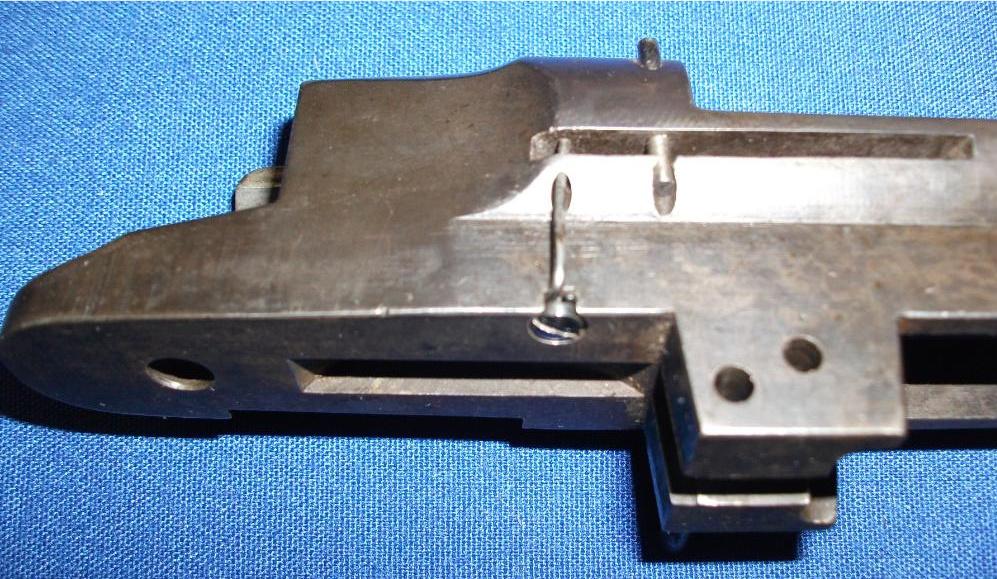

Back to the No4 T its one of the Hart conversions, I had a few ideas what I was going to do with it, but thought I,d take the stock off and see what had been done on the "conversion process" Although the front pad screw holes had been blanked, after removing the Brindles sight, the rear pad screw holes and bracket hole were still clear, after the stock was removed I was surprised there was no recoil lug !!

I don't know what the stock would of been like on the inside but I guess at sometime its been messed with as it doesn't ring home compared with the the rest of the rifle.

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

The Following 2 Members Say Thank You to bigduke6 For This Useful Post:

-

10-18-2012 04:47 PM

# ADS

Friends and Sponsors

-

Contributing Member

It looks like the rear of the action becomes the recoil lug.

-

-

-

Advisory Panel

Love the Spit Geoff. I was there in July 2009 the day before the show and saw some fantastic flying machines!

-

-

The Remington Lees used the draws as the recoil lug area.

"1879 Model" R-L

That's all you got to stabilize the action body against the recoil of the .45-70.

So having the rear of the action as well to act as a recoil lug is a bonus!

-

The Following 2 Members Say Thank You to jmoore For This Useful Post:

-

To me it just seemed a pointless exercise to go to all the trouble of removing the butt socket and with the new trigger (the draws not doing anything in the stock) I would of thought they may of added something to beef it up, the rear of the action is only a few MM, and has some filler in, it is in compression with the stock via the two allen screws that fit through the trigger guard, similar to your first Pic JM.

Last edited by bigduke6; 10-19-2012 at 07:05 AM.

-

-

Hmmm, I suspect the butt socket was added partly due to the lack of recoiling surface in the Lee design. The 1899 Lee in 30-40 had that area enhanced, too. Seems not a well thought out way just to get a one piece stock. Which helps shootability how?

BTW, it wouldn't do to try and stabilize the entire action bottom on this set up as the rear locking lugs means the action front will squirm a few thouandths every shot. Getting that to work is making me little pea brain squirm!

1899 Lee:

Last edited by jmoore; 10-19-2012 at 08:03 AM.

-

-

The butt socket was added on the Enfiield at the insistance of the Small Arms School, trials due to the flimsy nature of the small of the butts of the Remington-Lees that broke during the bayonet fighting phase of the trials. I don't know if this what you meant JM but that's the reason we did it

-

The Following 4 Members Say Thank You to Peter Laidler For This Useful Post:

-

Contributing Member

And a two piece stock was a logical progression for the British Army: the butt of Lee Enfield bolts in to its socket just like its beloved and indestructible predecessor, the Martini Henry.

Army: the butt of Lee Enfield bolts in to its socket just like its beloved and indestructible predecessor, the Martini Henry.

-

-

I don't know if this what you meant JM but that's the reason we did it

That's it, but the bedding drama seems more certain to create split stocks even without buttstokes to the enemy types...

-

-

Legacy Member

The "slicking" of Lee Enfields by converting to use a one-piece stock seems to have gone in and out of fashion a few times.

I reckon the engineers at Enfield / Small Arms School got it right for a military rifle when they took the Lee mechanism and adapted it for a two-piece stock.

The rear-locking action does move and flex minutely when fired; the heavily relieved right side more than the beefy left side. We are talking tiny amounts here, but regular movement it is, just the same.

From a logistical point of view, the supply of wood for a Gew98 stock requires a substantial source of very high quality, LONG bits of tree. The clever chaps at the Arisaka plant overcame that by forming the lower section of their rifle butts by dove-tailing and gluing in an extra bit before final profile machining. Probably the very same reason that the Teutonic types went to laminated stocks on a grand scale.

plant overcame that by forming the lower section of their rifle butts by dove-tailing and gluing in an extra bit before final profile machining. Probably the very same reason that the Teutonic types went to laminated stocks on a grand scale.

On top of the tree issue, there is virtually no way to accommodate soldiers at the extreme ends of the height scale with a CONVENTIONAL, wooden, one-piece stock.

Theoretically, a one-piece is better for bedding. However, no matter what applies to nice sporters that see very little bayonet fighting, a MILITARY rifle has to be built for seriously rough handling. The theoretical disadvantages of a separate fore-end were neatly overcome by the clever application of such bedding devices as the various plungers, collars and bearing points in that separate fore-end. The No4 carried on the idea. Interestingly, using the SAME ammo in a very different barrel required a very different approach; a simpler one, as it turned out.

Last edited by Bruce_in_Oz; 10-20-2012 at 03:26 AM.

Reason: Typos etc

-

The Following 2 Members Say Thank You to Bruce_in_Oz For This Useful Post:

Information

Information

PM

PM