-

Originally Posted by

dman69

Hi Tom, idiots weekly question - this is for wood, or metal working ? Being an accountant, I don't know much about such things, but I'm happy to nod my head approvingly, having benefited from your handiwork before! What sort of applications does it have ?

Ill use it for steel and wood, but it's meant for steel. I can see myself making and modifying parts, like illustrated by Jmoore, inletting stocks, cutting barrel channels, cutting extractor slots in newly threaded and chambered barrels, making tools, making bedding blocks, fitting sights to rifles/pistols, drilling and tapping tasks. I sold my drill press to help cover the cost, so it will do all my drilling. I think I'll be using this all the time.

-

The Following 2 Members Say Thank You to tbonesmith For This Useful Post:

-

01-12-2013 03:11 PM

# ADS

Friends and Sponsors

-

FREE MEMBER

NO Posting or PM's Allowed

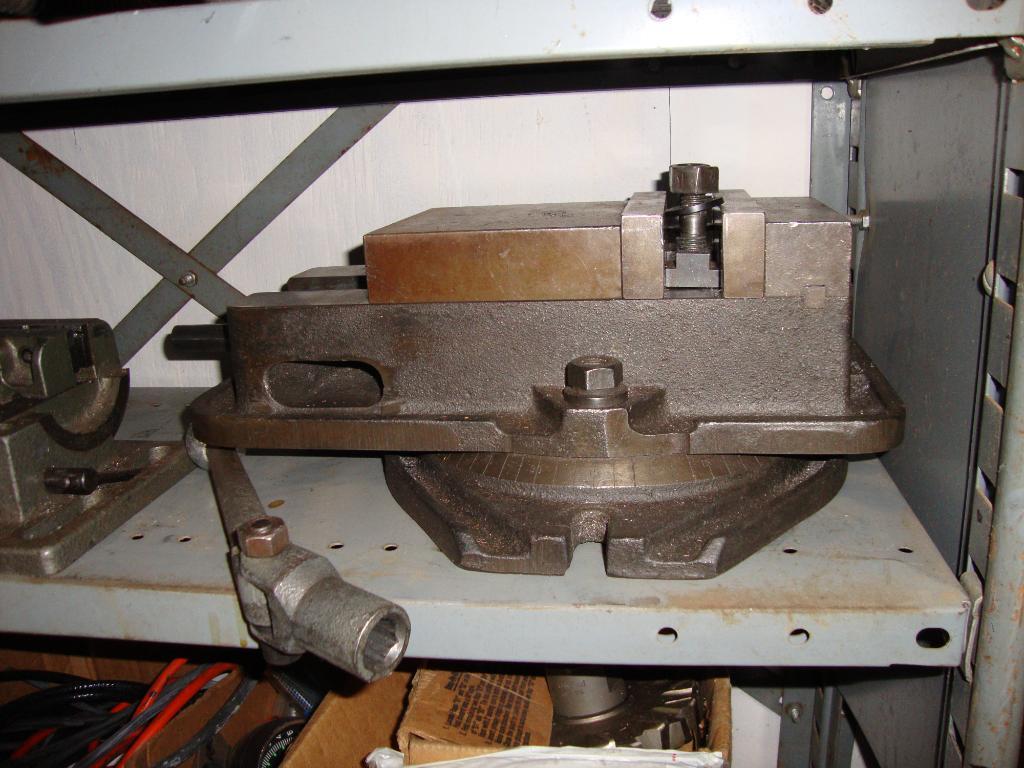

That mill looks solid but compact. Even large shops seem to get crowded over time so for me that is a plus. DRO and auto X feed are nice additions too. A Kurt vice would be the cherry on top... if you can find one that is reasonably priced.

May your mill track true and your chips break clean.

-

-

-

I ended up getting 5" vice, as the 6" was just too massive, maybe on the next upgrade, but I think this is adequate for a good long while. I levelled it up with a precision level using some M10 rod and nuts and washers for jacks, keeping them as short as possible (10-15mm of protrusion), and is seems to be pretty happy. All the extras seem to work well, coolant pump, DRO and autofeed. I adjusted the gibs and I couldn't get all the play out of the table in the Y axis, but on reflection I think what I'm feeling is the backlash. I'm pretty sure the leadscrew nut can be spread to accomodate this... I'll have a look today.

Faced off some stock and its pretty stable, adequately powerful and nice and quite. All good so far.

-

Thank You to tbonesmith For This Useful Post:

PM

PM