-

FREE MEMBER

NO Posting or PM's Allowed

Where to purchase Gas Check tool ?

-

03-11-2009 08:45 AM

# ADS

Friends and Sponsors

-

Legacy Member

I bough one called Freechex Tool from E-Bay

-

Thank You to Ron in Pa For This Useful Post:

-

-

FREE MEMBER

NO Posting or PM's Allowed

-

Legacy Member

Before you buy one of the freechex, bear in mind that you'll be running aluminum oxide, a powerful abrasive, down your bore if you use aluminum to make them. I bought one, just to keep around in case one can't get gaschecks in the future, but won't be using any of the more than plentiful aluminum printing plates I can get at work. While you're at castboolits, check the group buy section for regular copper checks. One could also buy copper sheeting to use with the freechex, but I've got better things to do with my time, like shooting.

-

-

Legacy Member

I had read on another forum that if you use aluminum cans, they are coated, so the metal doesn't actually touch the bore, Ray

-

-

Legacy Member

Aside from that, if you are using them and you run them thru the sizer lubricator soon after making them, they will be coated with a thin layer of bullet lube. That by itself should prevent oxidation of any exposed metal.

When they tell you to behave, they always forget to specify whether to behave well or badly!

-

-

FREE MEMBER

NO Posting or PM's Allowed

Freechex/Freechex II gas check tool

This kit sold only thru/on E-Bay by a gentleman named Codarnell is a device that cuts/punches discs out of aluminum beverage cans or sheets of aluminum or other metals such as brass or copper, The discs are then formed into cups or gas checks. Beverage can aluminum is a bit thin...around .004-.005 and this is sometimes a loose fit to the bottom of the bullet. It can be remedied by a drop of krazy glue. Other users form two discs together which produces a check of approx .010 thickness which also brings the outside diameter up to the level of the lower bullet band and fits tighter. Some folks have come up with using roof-chimmney flashing, available in Lowes or Home Depot and it is reportedly .010 thick to start with and very economically priced. Aluminum "for sale" signs sold in Walmart also work. Brass and copper are readily available, but will cost more. Another source of thicker aluminum is a bottle used by Budweiser if one is interested in adding the cost of beer to the GC. The cost comparison to buying new gas checks from Hornady(who makes all commercial gas checks and Lyman who adds their "cut" to the Hornady price) or Lyman is incontestable. Depending on the size...the price is a major ripoff-in the $20-$30. range so investing in a Freechex kit for approximately $30 + postage; it will be recovered by you if you make approx 1000-1500 gas checks and you will forever be ahead after that. The punch in the Freechex kit is readily sharpened if necessary and the punch can be readily replaced as it is a standard hardware size/item. It is a slow system/process depending on the dexterity and perseverance of the operator, but well worth it. A mallet or hammer runs the process, but those folks with machine shop skills and some machinery have adapted the kit to work on a standard reloading press. The maker of the kit is a friendly and approachable guy who communicates and helps with advice if necessary. He can be contacted thru his E-Bay address. He does special order sizes.

Now about the subject of Aluminum Oxide. This compound when used as a coating in solid crystal form is an effective abrasive for grinding wheels and sandpaper, etc. BUT aluminum beverage cans are coated internally to resist liquids that have carbonic acid in them, such as soda etc., and have a paint or tarnishproof coatings on the outside. Anyone who took science in/at any level of school or high school chemistry learned that to have an oxide compound of anything formed, you have to have oxygen present/available. So no oxygen=no oxide! If you use chimmney flashing you can keep the discs or the formed checks in a pill bottle or small sealable plastic bag and whatever oxygen gets in at all will be infinitesmal in terms of oxide reaction. This means that it would take a lot of years to be able to be measured on an electron microscope much less be of any measurable effect on a steel rifle barrel after ten thousand++ shots. Nevertheless if you still believe otherwise you can always use copper or brass instead of aluminum. Just for the record I have been feeding a number of Garands, Springfields and 30-30's with gas checks made out of Aluminum from pop cans for quite awhile now and they are working as well as any commercially made copper ones that I ever used. The groups are good and the cost is almost non existent. Ok there is the time and labor, but nobody bats a thousand. Its your call. Good shooting. JC

-

FREE MEMBER

NO Posting or PM's Allowed

For those worried about oxides, put the disc or chex in your tumbler and polish like brass, with New Finish car wax.

Store the unused chex as stated above in an air tight container with a rust preventing vapor chip and quit worring. If any mocular level oxides are present, they will only improve the internal barrel finish.

Have you ever wished for a shiny bore??????

-

Legacy Member

The shiny bore is what clued me in to aluminum oxide. A New Zealander had been using printing plates, made mention of his shiny bore. I read another fellows post about oxides. To that the New Zealander replied that there were no oxides, the plate was coated. I've been working in printing since 1975, since the 80's the majority of plates have an anodized surface. Looked up anodizing, this is the process of creating a few atoms thick layer of aluminum oxide on the plates to prevent further oxidation. Prior to anodizing, if a pressman didn't gum a plate before going to lunch, the plate was sometimes ruined by oxidation when the operator returned. Some plates are only anodized on one side, some on both. Truly a shame, because the plates where I work are .011 thick, just right for the free chex. I'll keep a free chex, and a stash of the plate material for emergency use, but it just isn't something that's going through my barrel on a regular basis. Might use some for fire lapping though, sounds like a good what to get rid of that frost in the grooves! Some of what you fellows above are reading on cast boolits has been my alter ego's writing - andiarisaka aka madsenshooter

-

-

Legacy Member

I bought a 30 cal Freechex Tool for my 30-06 rifles. I use the Aluminium from a 3 liter can of imported Olive Oil. It mikes out at .010-.011 which is about the same as commerical checks.

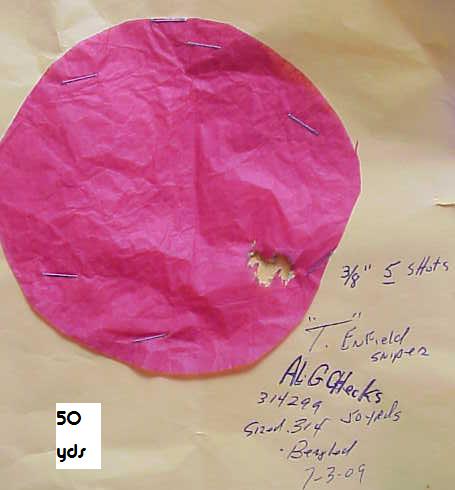

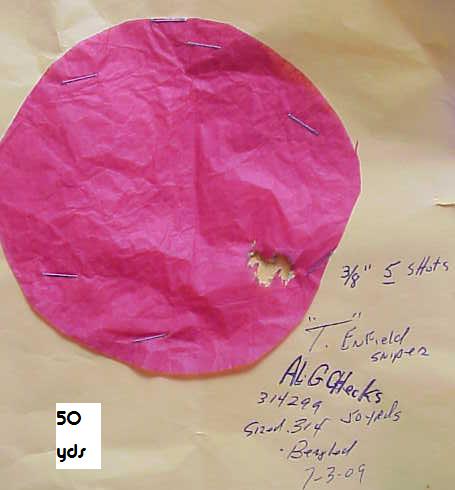

I miked the the two brands of 30 cal checks I have and found they were 30 cal on the bottom and flared out to about .312-.314 at the mouth. So I just flared out the mouths of the checks I made so they would be the same to work in an Enfield and a Japanese rifle having .311-.315grooves. I just used the rounded head of a machine to flare them out.

rifle having .311-.315grooves. I just used the rounded head of a machine to flare them out.

Here's my first test 50yrd, 5 shot group I fired with the checks I made and that I flared. I used the same powder and bullet I used with commerical checks. It was actually better. Ray

-

Thank You to rayg For This Useful Post:

but don't know if I was in time to meet the deadline. So thanks again.

Register To Reply

Register To Reply