-

FREE MEMBER

NO Posting or PM's Allowed

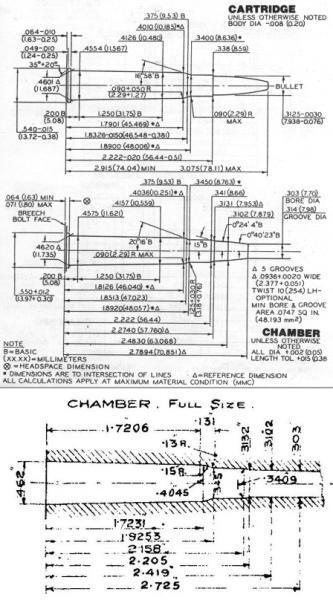

303 British Chamber Diagram

Last edited by cprher; 07-04-2015 at 03:11 PM.

-

07-04-2015 02:50 PM

# ADS

Friends and Sponsors

-

-

-

-

FREE MEMBER

NO Posting or PM's Allowed

No, not a chamber reamer, but custom match bullets. The guy who is helping me is a bench rest guy and needed info on throat and lead to determine if the bullet design he has will work.

Keith

-

Legacy Member

The trick would be this:

1. If using "commercial" bullet forming equipment, such as supplied by Corbin, etc, go with a flat-based, hollow-point design.

2. Match the exterior profile of the "proper" Mk 7 bullet.

3. Select a core that will give correct weight for the finished bullet.

4. Don't bother with the aluminium / fibre "nose filler", just leave an air-space to "replicate" as best as possible, the "base-heavy" balance.

Some "fiddling" will be involves as the original jackets are a bit thicker than many modern "sporting" jackets.

The key characteristics are:

Overall length

Total weight

Balance

And, of course, diameter. On this last item. give serious thought to a nominal diameter of 0.3125" instead of the "usual" 0.311".

Final "touch" would be to slightly "dish" the VERY flat base: ABSOLUTELY NO boat-tails.

Get the profile / shape wrong and they will not seat or feed correctly. Neither will they come close to tracking "original" exterior ballistics much past 200m.

Always remember: Any Lee Enfields (or P-14), and we can probably include the Ross, made much after 1912, and certainly post WW1 SMLEs, No4s and 5s, were built AROUND Mk7 ball. The rifles were tuned to the ammo,, not the other way 'round.

-

The Following 13 Members Say Thank You to Bruce_in_Oz For This Useful Post:

Atticus Thraxx,

Brian Dick,

HarryB,

jrhead75,

Peter Laidler,

Richard Hare,

Ridolpho,

Robert303,

Sapper740,

sean6.555,

Seaspriter,

Simon P,

tbonesmith

-

FREE MEMBER

NO Posting or PM's Allowed

In Corbin terms, you want a concave open base with base round over die set, 8.2 ogive

-

Wise words there from Bruce in Oz, (thread 4; last para.) that Armourers were told to ignore at their peril. That the BULLET is the weapon. The case and propellant are the means of moving it on its way and all the rifle does is to point it in the right direction and impart gyroscopic effect to aid its accuracy

-

The Following 8 Members Say Thank You to Peter Laidler For This Useful Post:

-

Legacy Member

I have asked for official British ordinance drawings many times but I have never seen one. There are no drawings to date that dimension and tolerance both the chamber and cartridge.

ordinance drawings many times but I have never seen one. There are no drawings to date that dimension and tolerance both the chamber and cartridge.

I got all of the data used by a leading maker of reloading dies. All his data was from both commercial and military sources in the UK. None of the drawings were fit to manufacture anything.

I have once fired brass from probably a dozen different rifle #4 rifles and the chambers vary significantly.

Last edited by ireload2; 07-08-2015 at 01:27 AM.

-

-

-

-

Legacy Member

CNC turned solid bronze with several grooves to accommodate the metal displaced by the lands? Look, Ma; NO LEAD!!

Good point about the Cordite as well. It burns fairly quickly compared to modern ideas about "ideal" burn rates.

However, given that the U.S. and Canada made vast quantities of "Mk7" ball ammo, in BOTH world wars, What were they using to fill all those millions of rounds?

made vast quantities of "Mk7" ball ammo, in BOTH world wars, What were they using to fill all those millions of rounds?

Some Canadian production used Cordite propellant and Mercuric primers, but to the best of my knowledge ALL U.S. production was fuelled by granulated, double-based Nitro-Cellulose propellants and ignited by lead-based Boxer primers.

And then there is the substantial output of .303 Ball and Tracer from the FN plant, especially post WW2. I suspect that they would have put some effort into matching "standard" Mk7 ballistics at least for the ball ammo, especially as much of this production was shipped in cases and packets labelled, "Pour BREN".

-

The Following 2 Members Say Thank You to Bruce_in_Oz For This Useful Post:

-

Legacy Member

I will dig around in the crypt.

Somewhere there should be complete drawings for SMLE and No4 barrels, complete with dimensions and tolerances for the chambers.

-

. If different depending on model/arsenal then I'm looking for the one used last for the No. 4 Mk 2 at Faz. I'm particularly interested in the dimensions of the neck, throat and lead.

Register To Reply

Register To Reply