-

Originally Posted by

Sentryduty

So who has a scrap rifle and a band saw? We can get right to the bottom of this!

LOL.

MAybe Anzac15 can help us out. He seems to come up with lots of local Milsurps. Maybe he knows someone who has old barreled actions or otherwise unserviceable 1888/05s that can be had for cheap. I could arrange pickup without shipping hassles.

-

-

02-04-2016 12:42 AM

# ADS

Friends and Sponsors

-

Contributing Member

Gotta say, since you lot have been at it, I've looked at mine a dozen times.

Sure looks like a weld job and silver soldered seam to me.

-

-

I get riveting and silver solder, but welding and solder? Now that's just weird.

-

-

Legacy Member

Originally Posted by

muffett.2008

Sure looks like a weld job and silver soldered seam to me.

Post a pic or two, be interesting to see.

It's possible to solder over weld (though I can't figure why anyone would want to) but you're in for big problems trying to weld over solder or brazing.

Last edited by vintage hunter; 02-04-2016 at 05:39 AM.

-

-

Contributing Member

Thats the pins that appear to be welded, the seam around the mating surfaces is where it appears to be silver soldered, it's just too neat a join to be just sitting there.

-

-

Contributing Member

Mine does not appear to have anything holding it other than the rivets which look exactly like rivets. They are perfectly round with perfect joint.

-

-

Legacy Member

Originally Posted by

muffett.2008

Thats the pins that appear to be welded,

That's a good possibility but I tend to believe any welding would've been done as a repair to ''tighten up'' a guide where the rivets worked loose. Perhaps this is what led to the belief the guides were welded instead of riveted as mentioned in post 3.

Originally Posted by

muffett.2008

the seam around the mating surfaces is where it appears to be silver soldered.

I've looked at a good many close up photo's of 88/05 charger guides and I've yet to see anything that would suggest they were attached by any method other than riveting. Soldering generally leaves a tell tail bright ring at the joint and I've seen no evidence of it so far.

Originally Posted by

muffett.2008

too neat a join to be just sitting there.

Joints between parts with machined mating surfaces can be awful hard to see, especially 100+ years later when any minute gaps would've long since filled with fine crud and/or rust.

Last edited by vintage hunter; 02-04-2016 at 04:12 PM.

-

-

Contributing Member

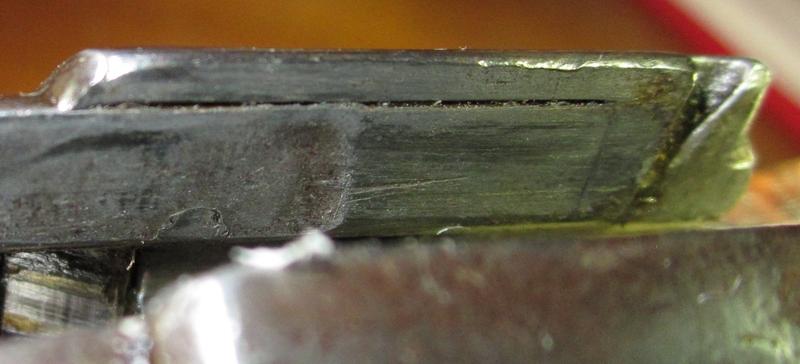

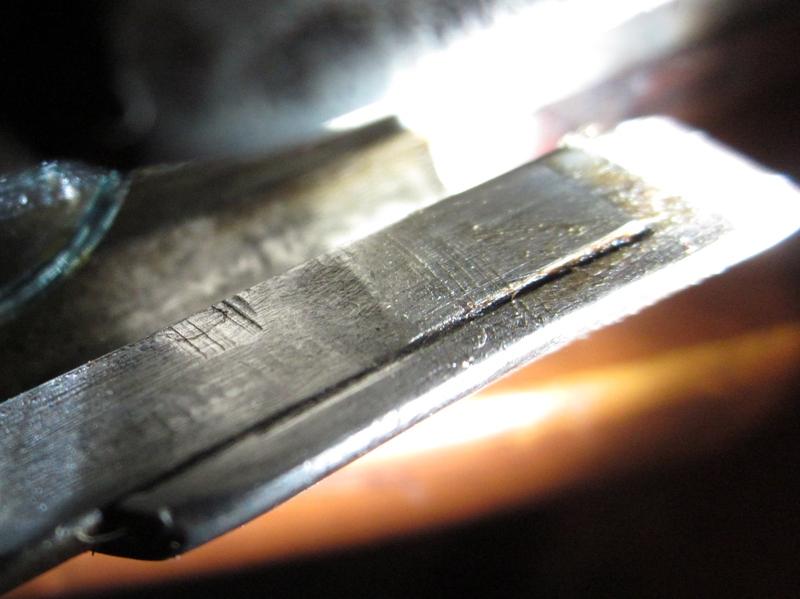

Another dull pommie day, so dragged the old girl out for a few pic's.........used a mirror in the bolt channel, so you can see both sides at once.

Attachment 69540Attachment 69541Attachment 69542Attachment 69543Attachment 69544Attachment 69545Attachment 69546Attachment 69547

These pic's are of another one(borrowed for a look, different again)

Attachment 69549Attachment 69548Attachment 69550

The top rifle you cannot see any rivet sign on the inside face, the outside marks are very faint. note the joint around the right side plate, one shot shows the soldered joint after I cleaned the crud off.

The second rifle you can see both sides of the rivets on both faces.

-

The Following 4 Members Say Thank You to muffett.2008 For This Useful Post:

-

Contributing Member

muffett, Your top rifle does look like something happened with it but it doesn't look like it would have after coming out of the conversion so it may have undergone some sort of repair after they became loose. The bottom rifle looks like it should, that's how mine looks.

-

-

-

PM

PM