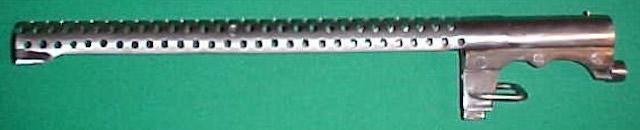

Apologies...had a brain fade - you should be looking at the East Taylor Stevens Heat Shield, not the Winchester 97/12 unit. (see photo below of East Taylor Stevens unit).

The Lug for the Bayonet Mounting Ring on the Stevens' "flares out", as opposed to the Lug on the 97/12 lug, which looks thinner and straight.

The Bayonet Mounting Ring on a 1200 Heat Shield "flares out" - like on the Stevens assembly (see below photos of real 1200 Heat Shield assembly).

Additionally, the East Taylor Stevens unit has the Heat Shield spot welded to the Bayonet Lug - similar to a real 1200 Heat Shield. M97/12 Heat Shields are riveted to the lug, which wouldn't be right for the 1200 Trench.

The "lip" on the 1200 Heat Shield Lug is not critical for what you are doing, as you are mainly looking for a reasonably close appearance.

As long as your barrel outer diameter (OD) is smaller than the internal diameter (ID) of the Lug Clamping assembly, you can use thin shim stock to tighten things up.

And, even if you barrel is slightly larger than the ID of the Stevens assembly, a competent gunsmith or machinist can ream out the ID - there is a fair bit of material on the clamping lug. I've had to do this before on other projects.

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

PM

PM