-

FREE MEMBER

NO Posting or PM's Allowed

Question about 1903 springfield Rockwell

We got in a 5 digit Rock Island made 03. We aren't much into it since the stigma but was curious what the Rockwell on the receiver ring should be? Ours tested out to 52 Rockwell mid way on the top of the receiver ring. Where else should we test it to see if it's a safe rifle?

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

02-07-2017 07:30 PM

# ADS

Friends and Sponsors

-

Legacy Member

NO five digit RI is "safe" since it is considered a low number. The "safe" serial number is usually is usually considered to be above 285,000.

-

-

FREE MEMBER

NO Posting or PM's Allowed

Question about 1903 springfield Rockwell

I understand, but I'm looking for technical information, info gathered from "safe action" Rockwell tests.

Pretty sure I'll get railed for trying to get info on a "unsafe" action but if a weapon falls within the safe specifications then why throw it out?

-

Contributing Member

For what I know they changed the hardening process. Therefore it might not be something you can simply measure by the surface hardness. Or in other words: why risk something for an item which is known to be in an unsafe serial range?

-

-

Advisory Panel

It's not a matter of throwing something out, these don't give warning when they break. They don't crack or just fracture, they shatter like glass. They go to pieces all at once and there's a danger there. I'm not sure you can forecast which is in this possible group except by the serial range. I wouldn't chance it. Just because they've been used for decades doesn't mean it won't happen...safety first?

-

-

Legacy Member

I'm sort of quoting off the study the Marines did of this in 1938. So honestly my knowledge is mostly only what I'm reading.

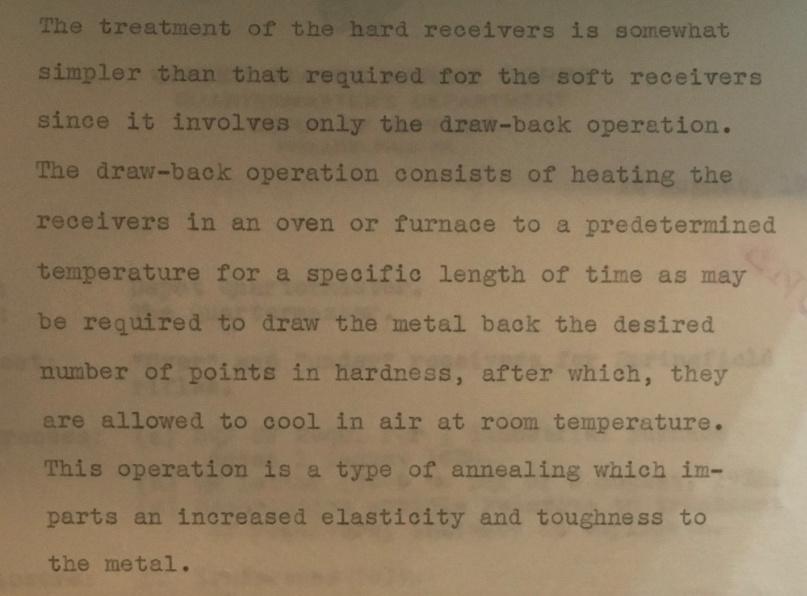

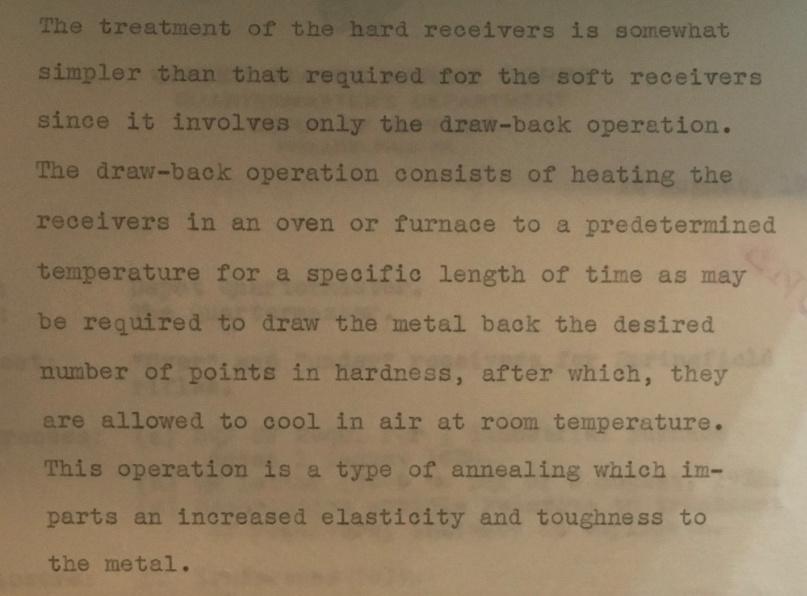

But the Marines report on the Rockwell hardness test states this. That both low and high number receivers were failing the rockwell test. If they were too soft, they were not as much of a risk as if they were too hard. If soft, the receivers could be used, but they would eventually stretch until finally the rifle lost headspace and would be unserviceable. If too hard, they were prone to shattering when you had a rupture. The hard receivers were the ones the Marines were concerned about. And they did have both Low and high number receivers that were too soft or too hard.

The Marines do state they have the ability to fix too hard receivers in what they called a "Drawback Process." They would heat the receiver to a certain temperature for a specified amount of time, that would draw the metal back the desired amount of points, and then they would let it air cool at room temperature. This brought back elasticity and toughness to the metal.

The Marines state the safe range for the rockwell hardness test is between 20 and 45 Rockwell "C" Hardness.

I hopet his helps you some in your search.

Last edited by cplstevennorton; 02-08-2017 at 01:18 PM.

-

Thank You to cplstevennorton For This Useful Post:

-

Legacy Member

Very interesting Steve. It was my impression that over hard crystalized steel could not be reversed. Any data on the Marines actually using the drawback process, or did they just scrap receivers due to time and other constraints.

This has come up before, and you would think Springfield would have done it with their resources if possible. Also no new companies with modern facilities have done it either.

I'm sure there would be a market to bring low numbers up to shooting status!

-

-

FREE MEMBER

NO Posting or PM's Allowed

I ask because as a machine shop, we have the equipment to heat treat and measure Rockwell. We're more interested in the possibility to rescue for testing, not resale

-

Advisory Panel

Originally Posted by

mwells72774

We're more interested in the possibility to rescue for testing, not resale

I guess you'll be able to tell us after...

-

-

Legacy Member

Originally Posted by

pickax

Very interesting Steve. It was my impression that over hard crystalized steel could not be reversed. Any data on the Marines actually using the drawback process, or did they just scrap receivers due to time and other constraints.

This has come up before, and you would think Springfield would have done it with their resources if possible. Also no new companies with modern facilities have done it either.

I'm sure there would be a market to bring low numbers up to shooting status!

You know to be honest, I can't really remember where they went from there. You see hundreds if not thousands of pages on the low number recievers in the Marine files, but most of the time you just see them concluded that they shouldn't shoot rifle grenades with low numbers to be safe.

Then in 1938, the Marines had a big push to try to fix receivers. Which they honestly had trouble with both lows and highs, which they called "Unders" and "Overs." That is when they started trying to fix the overs and unders with heat treament that were too soft and too hard. They claim in the study they could fix them. Hard receivers only went through the draw back process. The softs went through a heat treament with oil quench, and then a drawback process as well. But to be honest, I can't remember where it goes from there. I don't think they did it a long time if my memory serves me right. Now whether it just wasn't a success or the war was escalating and they were in a hurry and quit, I honeslty can't remember.

This was also about the time, they sent a rep to SA to learn how to do hatcher holes and enlarge the gas escape hole in the bolt. So they might have just screw heat treating the receives with heat treament and did hatchers as a much easier and quicker band aid fix.

If I get time early this week, I will dig those files out and see where it went. I just can't remember off the top fo my head. It's been a while since I looked at those and I've really didn't read that series of docs that close. I think it does explain why they quit doing it, but I can't really remember.

I do have the rockwell case study on hand though, because it explains some Marine traits on the rifles they rebuilt, so I have that filed where I know where it is is. But this is the process as they describe it on the doc for how they fixed hard/brittle receivers.

Last edited by cplstevennorton; 02-12-2017 at 08:28 AM.

-

The Following 2 Members Say Thank You to cplstevennorton For This Useful Post:

Register To Reply

Register To Reply