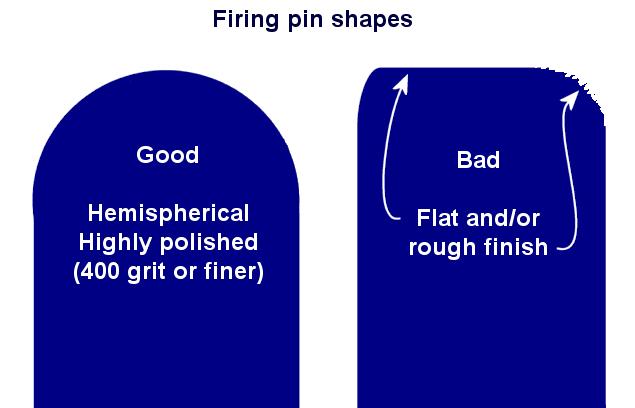

This problem has nothing to do with primer quality, headspace, case length, etc. It's the natural result of a rough firing pin tip, even if the irregularity can't be seen without magnification. Look at this enlargement of the intact primer shown above. See the jagged crater in the middle? That's the reverse impression of a seriously rough pin. (Imagine the different results from poking a toy balloon with a fingernail and with your elbow. Might help some folks understand why we need a smooth pin surface to avoid primer damage.)

There's no great skill required to polish a rough pin - just remove the bolt head and rub the pin's surface around on a piece of very fine abrasive cloth or paper held on your other palm. Thus cushioned, the abrasive will naturally produce a smooth, hemispherical tip.

If you polish off too much and end up with insufficient protrusion (under ~.040"), a new striker is the standard fix - but will require a striker removal tool and some study of what it takes to maintain the proper relationship of bolt, bolt head, cocking piece, and striker.

Contact of striker flange and rear of bolt head (B) controls pin protrusion (A).

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

PM

PM