-

FREE MEMBER

NO Posting or PM's Allowed

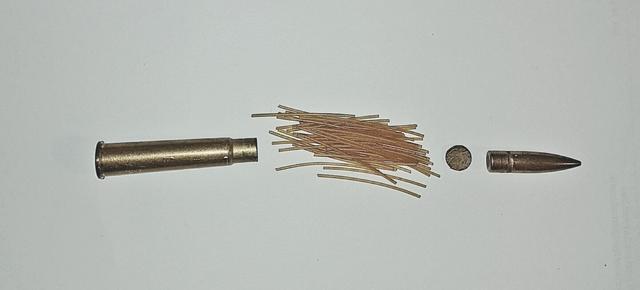

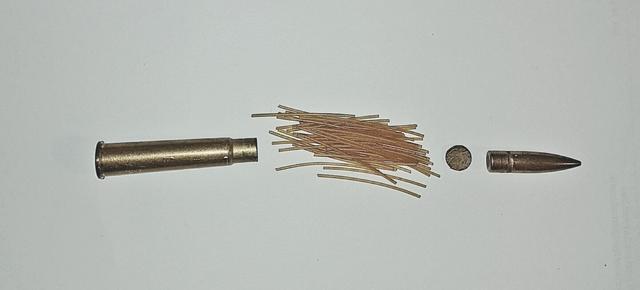

Grease groove in WWII .303 bullets important or not ?

I use to salvage bullets from (corrosive primed/cordite loaded) WWII ammo before handloading them with modern primers and powder. However, I tumble pulled bullets prior to handloading until they come out shiny. However, I've noticed that the original bullets carry a grease groove which is also cleaned out during tumbling ; then, after being sorted in weight lots, they shoot quite accurately on top of N140/40.0, though. Am I wrong in tumbling the bullets and should I preserve the greased groove ?

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

Last edited by André; 12-10-2017 at 09:28 AM.

-

12-10-2017 09:25 AM

# ADS

Friends and Sponsors

-

Legacy Member

The cannelure is not a grease groove. It's there to aid guide the crimping.

-

The Following 3 Members Say Thank You to RobSmith For This Useful Post:

-

-

FREE MEMBER

NO Posting or PM's Allowed

Originally Posted by

RobSmith

The cannelure is not a grease groove. It's there to aid guide the crimping.

It's still filled with grease, though...

-

Advisory Panel

I think what you're seeing isn't grease but a sealer to make them waterproof. Most if not all factory loaded military ammo will be sealed.

-

-

FREE MEMBER

NO Posting or PM's Allowed

True, it could be sealing wax indeed. Then, I guess it's of no importance in reloads whether bullets are tumble cleaned or not ?

-

Legacy Member

No it's not important. It may increase the accuracy of the bullet a little bit without the sealant on them.

-

-

Advisory Panel

It's more like a tar coat to seal. I used brake cleaner sprayed on them and then polished them in a big towel before using them. All the tar coat came off.

-

Thank You to browningautorifle For This Useful Post:

-

Legacy Member

It is grease . Since the Enfield was a low powered action they did everything they could to get more velocity and keep pressure down . An undersized bore riding bullet , slick jacket material , and a lubed bullet . It is not a sealer , that is why there is a grease Groove .

-

-

Legacy Member

Comment. Never seen any military or commercial jacketed bullet requiring grease; crimping cannelure yes. Never knew the Enfield was a low powered action either, or about the "undersized bore riding bullet". Could you provide some facts on this please.

-

-

Legacy Member

The Enfield bolt locks by the middle of the bolt on the receiver bridge , it has no locking lugs . The proof would be looking at it . And no the little lug ion the rear of the bolt is not a locking lug , it is a cocking assist .The proof would be reading the original patent description . . The Enfield was originally a black powder action , was later used with low pressure cordite and it was not even cleared for Nitro powder except for war emergency . Read original British military ammo test reports .The groove dia is around .314 on the average with a .3095 dia bullet . Again the proof would be measuring real rifles and bullets . Bore riding was used my all militaries in their early small bore rifles . Again just look . I have a vast collection of original ammo and the crimp is not at that groove and the grooves are all full of grease . Again for proof just use your eyes .

military ammo test reports .The groove dia is around .314 on the average with a .3095 dia bullet . Again the proof would be measuring real rifles and bullets . Bore riding was used my all militaries in their early small bore rifles . Again just look . I have a vast collection of original ammo and the crimp is not at that groove and the grooves are all full of grease . Again for proof just use your eyes .

-

Information

Information

Register To Reply

Register To Reply