-

Originally Posted by

painter777

After looking at the bottom left guide way that the bolt's left lug rides on top of .... I seen the shape of it and thought it was messed up, with metal missing.

Originally Posted by

a1parrothead

Mine has some wavy cut outs and I don't know if that's machining or not.

You're seeing what I tried to describe in my Quote above from post #9 on page 1. Not knowing any better at that time, I thought that carbine was ruined.

Those wavy cuts allow for the needed left bolt lugs movement, while the bolts right lug is being rotated while attached to the Op slide. One notch on that left rail IIRC allows clearance for the rim of the next casing as it feeds up.

I'll try to put the pictures you requested up Saturday for your comparison.

Charlie-Painter777

-

Thank You to painter777 For This Useful Post:

-

01-12-2018 08:21 PM

# ADS

Friends and Sponsors

-

From another forum...

This guy had 2 bolts break. In the very end he replaced the Op slide which cured his problem.

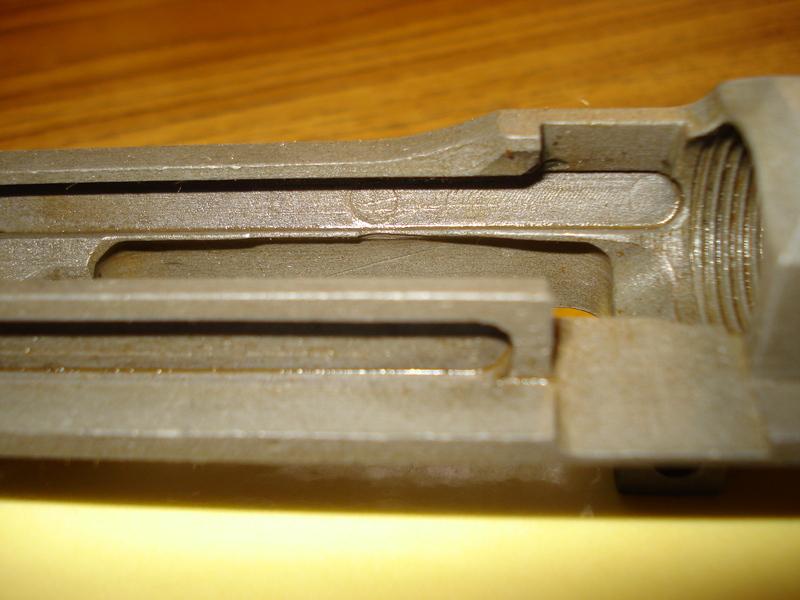

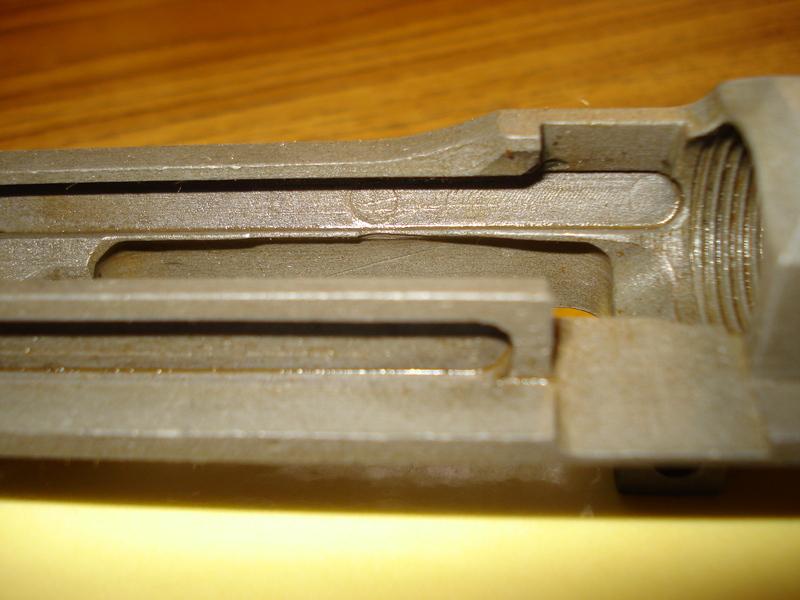

Picture is his.... showing the left recess.

BQ97 Added: The reason your bolt broke is because it momentarily hung while rotating out of battery. The evidence is in the second picture in the first link you posted. When this happens the right lug takes all the strain at an odd angle. Sooner or later the lug cracks then breaks off entirely.

This is the 2nd picture referred to by BQ97. He makes a great point, if the Op Slide had a area it strained over to operate...... Like Burrs... no lube... etc. That's why I say to look over and inspect ANY groove and pivot point

Link to the story:

M1CarbineForum - broken bolt - Powered by ForumCo.com - The Forum Company

a1parrots chip is lower, causing one to give his problem a little deeper thought. Still have those Flattened primers on my mind. Just typing out loud

-

-

-

Advisory Panel

You can bet the flattened primers have lots to do...extra op slide speed would do a number on the bolt lug. And raise a welt on the other side.

-

The Following 2 Members Say Thank You to browningautorifle For This Useful Post:

-

You can bet the flattened primers have lots to do...extra op slide speed would do a number on the bolt lug. And raise a welt on the other side

Exactly Jim,

Quicker and harder than my Mother could snap a crab apple switch over my rear end !

Enjoy Your Weekend

CH-P777

-

-

-

-

Flat surface on inside of lug recess

Below:

Bottom view of 'Wavy' cut on receivers left bolt lug rail

Note the right bottom corner of the bolts left lug support appears to have a 45 degree type angle like a Miter

-

Thank You to painter777 For This Useful Post:

-

Originally Posted by

manteo97

What maker's marks were on the bolt, ie who made it?

Manteo,

His bolt was a round one marked W for WRA. I believe it had the pointed right lug. I'll attach a picture of the Damaged W Type III bolt below.

Here is His first post about his new carbine........ before having the bolt failure:

https://www.milsurps.com/showthread.php?t=63255

Charlie-Painter777

-

Thank You to painter777 For This Useful Post:

-

Parrot,

Here's a link to my last broken bolt. You might find it interesting to read:

https://www.milsurps.com/showthread.php?t=46709

Charlie-Painter777

Last edited by painter777; 01-17-2018 at 09:06 PM.

Reason: fx typo

-

Thank You to painter777 For This Useful Post:

-

FREE MEMBER

NO Posting or PM's Allowed

Charlie,

Thanks for the picture and the link. I read it, and it feels painfully familiar.

If my receiver is salvageable, I think I am going to have 2 bolts properly fitted for it while its at Fulton.

Jeff

-

MAKING IT EASIER ON OUR SHOOTER CARBINE

I'll try to find time this week and post a new topic IMO and thoughts of how one should set up their 'Used Often' shooter carbine.

Reason being that use of later style parts with there upgrades can be easier on the ole gal.

To include type of Op slide, Op slide spring, Bolt, Sear, Hammer spring, Extractor, Ejector and Firing pin.

I'll list what I'd recommend and look for others opinions and suggestions.

So Parrot.... Don't rush off for a few bolts just yet.

Thx

CH-P777

-

PM

PM