-

FREE MEMBER

NO Posting or PM's Allowed

What to do about headspace after #4 bolthead?

What to do about headspace after #4 bolthead?

Okay, first of all my Model #4 Mk1 rifle's head space is okay (gunsmith inspected). However what do I do when the headspace gets to big when the bolt head is currently a #4? Do I add a spacer? Try a different #4 head? Rebarrel? Any suggestions? Thanks.

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

04-29-2009 04:51 PM

# ADS

Friends and Sponsors

-

Legacy Member

-

-

There was a thread some time ago about 1950's trials aimed at establishing the viability of a higher size bolt head. It was deemed that............ anyway, someone will repeat the findings but the long and short was that if you can't get CHS with a No3 bolt head and a new bolt/bolt head, then it indicates a worn body

-

-

Legacy Member

There was a thread some time ago about 1950's trials aimed at establishing the viability of a higher size bolt head. It was deemed that............ anyway, someone will repeat the findings but the long and short was that if you can't get CHS with a No3 bolt head and a new bolt/bolt head, then it indicates a worn body

CHS - Body and bolt wear

Posted By: Peter Laidler

Date: Mon 28 Apr 2008 9:17 am

You should all read and re-read this if you have ever thought about CHS, body wear or fitting a new bolt, especially in response to the recent thread about the matter.

I was having a chat to one of the most senior examining Armourers at a huge Base Workshops at Warminster a few days ago. Long retired, he was a 1930's apprentice and one of the very strict examiners. I was asking him about chroming bolt heads to get longer life out of heads bolts and bodies when he reported back something that was VERY interesting.

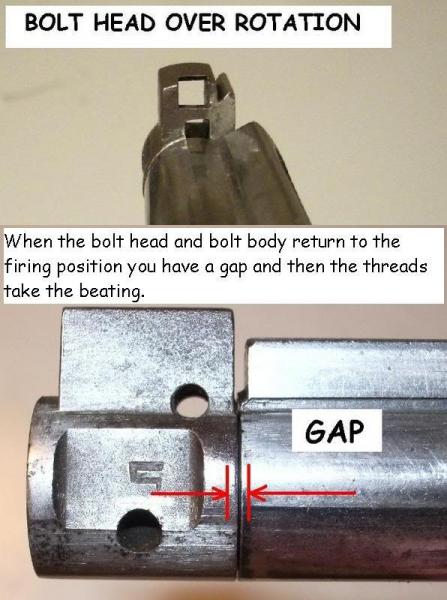

He said that during the mid 50's, there was a plan mooted to make a No4 size bolt head available so as to decrease the number of old wartime/tired/just plain worn out rifles being condemned as unfit simply because of insufficient CHS. The alternative was to increase the MAX CHS to .078".

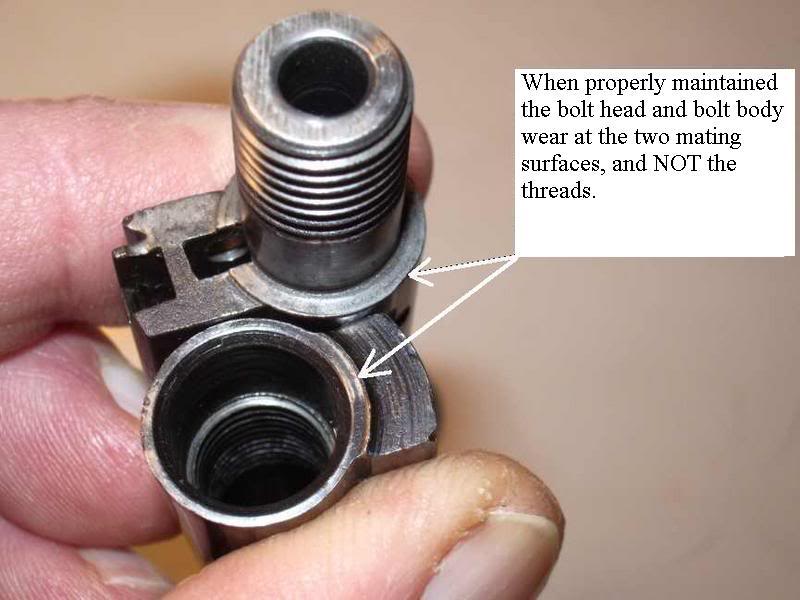

He was involved in this project as the research Officer, so was in from the start. The PROBLEM was that once the BOLT, Inspectors, Gauge (a calibrated slave bolt used to test wear) plus a calibrated No2 bolt head (No3 not permitted at Base/Factory don't forget) had been inserted into the inspectors gauge bolt, then making a further bolt head available was palliative and not a cure because these simple tests indicated that it was the BODY that was worn and not the bolt or the face of the barrel. And thinking about it, while it's obvious really, it's absolutely correct!

Another problem they encountered was that with the speed of wartime production, the induction hardening of the bodies was at best, mediocre, and at worst, sometimes virtually non existant. The hardening sometimes had no depth and it was tested at Base Workshops by the old IZOD impact test method. Apparently, all manufacturers were as bad or good as each other including Savage and LB (I bet that has shocked a few of you who were probably lead to believe that some makers were 'better' than others......)

I spoke about resurfacing bolts but he just shook his head sternly and wagged his finger as if to say. 'No, it's the BODY that's worn beyond the point of no return and once the hardness is gone, then there is no cure.'

There, that's straight from the horses mouth and it doesn't come any clearer or louder than that. If you cannot get CHS with BOTH bolt lugs bearing evenly using a No3 bolt head, THEN trying a new bolt, then it is the BODY that is finished. Sorry about that.....................

-

-

Banned

I found this on a Golf Course, it was very strange day everyone was yelling Foooour!

-

Legacy Member

Bolthead with N04 stamp

I came across a bolthead stamped 4 earlier this year, only one I have ever

seen, used it recently to headspace a tidy No4 Mk11! Was a few thou longer than a 3, used it because it didn`t overthread. It didn`t have any markings on it so I assume it was a commercially made one? Australia ? Does anyone out there know?

? Does anyone out there know?

-

-

No4 boltheads are a bit of an enigma. Maybe someone ought to do a steel analysis on one and compare it with a bog standard No 0,1 or 2.

I say this because it can't/won't be a factory made bolt head (?) because FTR/Base Workshops would reject bodies that wouldn't CHS on a 0 1 or 2 bolt head using the GAUGE, dummy bolt, armourers. And there was never such a beast as a No4 bolthead in UK or NZ

or NZ military service

military service

Can anyone identify any other marks on a No4 bolt head? What about a visible proof mark?

-

-

Legacy Member

I have two.

One is brand new, .642 in length. Marked with an "M" and the broad arrow.

The other is "well used", .642 long. It has an "F" or "E" and "2??" in a box".

A search through 3-400 units came up with only two of the beggars.

-

-

Originally Posted by

Timmer

Okay, first of all my Model #4 Mk1 rifle's head space is okay (gunsmith inspected). However what do I do when the headspace gets to big when the bolt head is currently a #4? Do I add a spacer? Try a different #4 head? Rebarrel? Any suggestions? Thanks.

If you want to learn more about the very basics of "headspace", Parashooter published an excellent teaching article in the Technical Articles for Milsurp Collectors and Re-loaders(click here)

Headspace 101 for .303's (click here)

Regards,

Badger

-

-

(Deceased April 21, 2018)

Got to agree on the bolt heads. If headspace is correct now, you are NOT going to be able to shoot the rifle enough to change it.

Register To Reply

Register To Reply