-

Tips Needed For Removing Dents

Can anyone share tips on pulling wood dents?

I'm often asked for tips but I rarely take this on.

The few times I have I'd poke a few fine holes with a needle point then use a eye dropper with warm water and a little Dawn dish soap. I'd try to keep the area damp for a couple days, then use a damp rag and soldering iron tip. Results were better........ but nothing above a C+ if I'm grading myself on a Curve

I've got some really beat up stocks I've kept around to use as patch wood.

Been curious about trying a steam box....... But how do you keep it from warping?

Even tossed around the idea of a Recoil plate spot welded to a blank of steel with a pipe attached to mimic a barreled receiver.

Antique Furniture guy in town has a big tea pot type kettle he's put together that has a PVC pipe running up at about 2 'o clock from the spout. The spout is coupled to the bottom of the PVC pipe with a Y shaped black rubber hose. The top end of the PVC has a threaded cap on it with a few vent holes drilled in it. Next to the 'Tea Kettle' is a bucket to catch the back dripping steam/water that feeds down one end of that inverted Y shaped rubber hose. He uses it for misc chair legs, decorative mouldings.. etc.

I took a dented up Inland stock to show him and he felt strongly he could raise the dents by approx 75% Without harming the Crossed Cannons Stamp.

He's a Pro I'll give him that...... Though I still have a hard time believing that method wouldn't affect the CC Stamp.

This particular stock doesn't really have any $Dollar value.... so I was tempted to have him try it until he told me it would run about a $100.

So right now I'm contemplating making a smaller version for a Hand guard that I could use in the basement for now because it's to darn cold out in the garage work shop.

When I asked him about a dent right in the middle of a desk top he said he'd poke very small pin holes and then use a Hypodermic needle to inject all it would take. He wouldn't tell me what 'ALL' was. But as the mystery liquid penetrates farther along in time this will allow it to take more in as time passed. Then using a small heat pad or heat gun in intervals he could get it to raise....... sometimes raised above the surrounding surface.

Anyone have any methods or thoughts to share?

Thx

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

Charlie-Painter777

A Country Has No Greater Responsibility Than To Care For Those Who Served...

-

Thank You to painter777 For This Useful Post:

-

02-28-2019 03:16 PM

# ADS

Friends and Sponsors

-

Contributing Member

I did it only once, about 20 or more years ago.

It has been a fairly simple and raw thing. I'd just put a drop of water into the dent and let it soak in. The day after I'd put another one.

Slowly the dent surged and levelled. Last step was linseed oil .

.

I remember it was looking a bit rougher than the rest of the stock immediately before putting the oil on, because it had dried.

But after the oil, I could not find the dent anymore. It was like any other little sign.

But I must also say that it was a relatively deep but small and narrow dent. Nothing terrible.

34a cp., btg. Susa, 3° rgt. Alpini

-

The Following 2 Members Say Thank You to Ovidio For This Useful Post:

-

Legacy Member

I use a steam machine. Wouldn't recommend the needle approach. When I tried it it permanently left marks and really didn't that good of a job. Then I used an iron with damp cloth which works but is slow going for me. So the steam machine got put to use and worked faster.

The first machine I ran empty and put water in too soon after so it worked exactly once. Brand new machine. My mom gave me hers and it worked repeatedly. Never tried the dishwasher but it really seems like it would work well.

-

The Following 2 Members Say Thank You to tenOC For This Useful Post:

-

Legacy Member

-

The Following 4 Members Say Thank You to RCS For This Useful Post:

-

Originally Posted by

RCS

For dents I use the hot iron and wet paper towels, takes forever and sometimes not worth the time

I've used the wife's iron and folded wet paper towels on small dents with good results. I believe this only works when the stock has been stripped of any finish first, so the steam can get into the pores. - Bob

-

The Following 2 Members Say Thank You to USGI For This Useful Post:

-

Legacy Member

I also have used my wife's iron and wet wash clothes. worked pretty well.

-

Thank You to imarangemaster For This Useful Post:

-

Not sure if the Wife has a iron......

And I rarely see her use that bottom thing attached to the stove top....

If I hear a knock on the door or a DING...... It's Dinner time.

Sorry Boys..... Not much sleep lately

Charlie-Painter777

A Country Has No Greater Responsibility Than To Care For Those Who Served...

-

-

Legacy Member

Originally Posted by

RCS

If you read Rick

borecky

's Wisconsin Barn Wood Story on the top of the

M1

Rifle forum, some of these early stocks were M1 carbine, most that I saw were

hi wood too. While buying early M1 rifle stocks, I saw a carbine stock on the ground in nice condition and bought that too. It was a I.P. stock, and when

I unpacked it, I tried it on a carbine. It would not fit because the front end was warped. My friend Charlie Redfield (NJ) told me to get a wallpaper tray

which is really a small trough, fill it with water and place the carbine stock inside with a brick on top. Leave it for three or four days then take it out. It worked,

after the stock dried, I used

BLO

and it fit on a carbine barrel & action without any trouble.

For dents I use the hot iron and wet paper towels, takes forever and sometimes not worth the time

The steamer accelerated my dent removal time.

There's a smith process for bending stocks at the grip to fit a right or left handed shooter which is well know for shotguns. They take a normal stock, wrap a piece of cloth drenched in oil around the neck and add more heat over a period of time with a torch I believe. Eventually the bonds of the fiber start to slip past one another. They term it "cast on" or "cast off" depending on which way they twist the butt section to conform to the shooter, left or right. One way is right the other left.

It's probably not a lot different for warps in the forward section? I don't know.

-

Thank You to tenOC For This Useful Post:

-

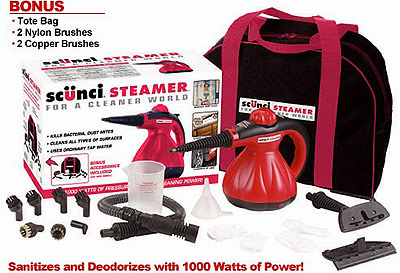

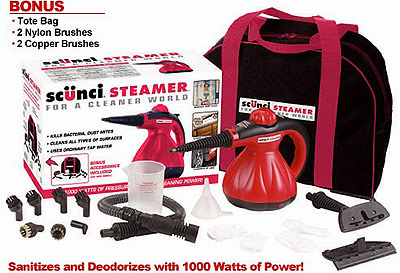

A steamer like this ?

I believe when time allows I'll build a Steam Pipe big enough to hold at least 1 Hand guard.

That way I can have one being steamed as I do other things. Will have to time it out to keep the tea pot full.

If a fail I'll have a patch wood piece to put back.

Appreciate all your input. Very helpful.. 5* worth

Thx

Charlie-Painter777

A Country Has No Greater Responsibility Than To Care For Those Who Served...

-

-

Legacy Member

That's exactly what I used. It says to wait for it to cool before adding more water once it runs out. My brand new one failed when I didn't.

-

Thank You to tenOC For This Useful Post:

PM

PM