-

Advisory Panel

I broke the little fingers off my first bolt tool as well.

I made a heavier one

-

-

03-30-2007 04:00 PM

# ADS

Friends and Sponsors

-

FREE MEMBER

NO Posting or PM's Allowed

I feel better now.

I got a complete bolt assembly in from Numrich.

The bolt wouldn't slide in at first. I noticed the bolt head wouldn't turn enough counter-clockwise to slip into the receiver. It was very tight, but I managed to unscrew it. Using 600 grit wet/dry sandpaper I smoothed the flat areas where the bolt and bolt head meet, then finished it off with 1500 grit. The bolt head lined up perfectly.

Took her to the range and it funtions great.

Lotta work to get a gun to go 'bang.'

Also ordered an issue WWII Enfield sling. My gun is a 1943, and the sling I got just happened to be dated 1943. Sweet!

-

Legacy Member

Originally Posted by

busdriver72

Well...this went good...............not!

After removing the correct screw and soaking in penetrating oil, I broke the two "teeth" off of the special removal tool. I think the striker had been in there since 1943 and it wasn't going anywhere.

You know, I think I'm gonna just get a complete bolt from Numrich for $44.95. That's less expensive than just getting the parts I need, as well as another special striker remover tool. When they say "complete" do they really mean it....head, striker (firing) pin, everything?

Wait! You have a new firing pin right? Read the last post in this thread.

Was the old bolt serial number matched to the receiver? What number was on the bolt head? Does the firing pin protrude more on the new bolt than on the old?

https://www.milsurps.com/showthread.php?t=341&page=2

Last edited by Cantom; 04-11-2007 at 06:22 PM.

-

-

Legacy Member

Everybody breaks the tool. Especially if the lugs are too soft, or hard as glass. A decent one that doesn't break thirty seconds after you brandished it at the bolt is worth a good deal.

-

-

17-4ph 180-200kpsi h.t. No breakee in 20years...

-

-

Legacy Member

I bought one of those striker removal tools for $50. It's not from Numrich.

I haven't tried it yet.

-

-

FREE MEMBER

NO Posting or PM's Allowed

-

(Deceased April 21, 2018)

There is the butcher method. pulling back the cocking piece to expose the striker and clamping a set of vise grips on the exposed part. Then holding the cocking piece in a vise and turning the striker with the vise grips to break it free, (often the striker is peened ) You lose nothing because the striker is already buggered,

Now as for turning the striker out one turn to make the firing pin move forward, that ain't gonna work, cause the collar on the striker is stopped by the rear of the bolt head.

-

FREE MEMBER

NO Posting or PM's Allowed

Removing firing pin

I ordered a firing pin tool from Numrich a long time ago. I was cast metal, and the teeth did not last very long.

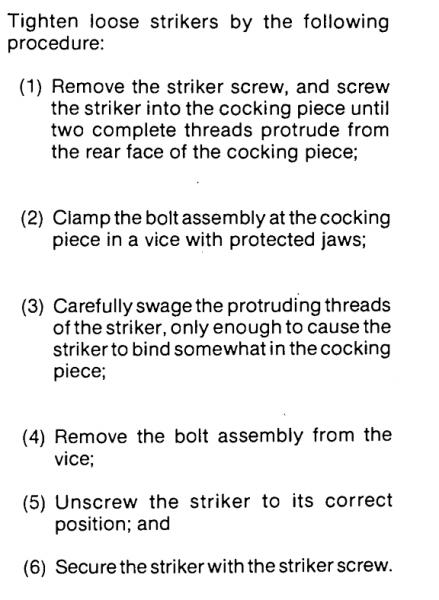

One thing. Did you remove the firing pin locking screw from the end of the cocking piece?

Remove it, then soak the cocking piece in penetrating oil. You might even heat the cocking piece slightly and apply the penetrating oil when it is WARM, not HOT. The heat will expand the cocking piece slightly, and break any "seal" on the threads.

Any good machinist can make you a STEEL tool for a firing pin removal. If you have a buddy with a metal lathe, it can be done in well under an hour, including a beer while you are admiring your handiwork.

I like things a bit robust, so I use a 3/4 inch diameter steel rod about 4 inches lone, put it in the lathe, and turn about 2 1/2 inches down to about 3/8 inch diameter. Drill a 1/4 inch hole, about 1 3/4 length inside the turned down diameter. In the large end, drill a 1/4 inch hole cross ways for a 1/4 inch x 3 inch bolt for a handle to turn the tool with. Now, you have to file two "fingers, about 1/4 inch width x 1/4 inch depth in the end with the lengthwise hole. These fingers have to fit inside the notches of the firing pin, and are rounded on the inside. It helps to have an old firing pin (or the new one) handy, and simply fit the fingers to the new one, ROUNDING OFF THE INSIDE EDGES to fit the round recesses in the firing pin.

Again, make sure you take the locking screw out of the rear of the cocking piece. After using penetrating oil, put the cocking piece in a padded vise, insert the tool, and see if you can unscrew the firing pin.

The new firing pin should protrude from the face of the bolt approximately .040 inches.

Note. Sometimes people disassemble the firing pin, and screw the firing pin in one too many turns. As mentioned, you might be able to simply unscrew the bolt a turn or so, IF THE FIRING PIN IS ROUNDED, AND NOT BROKEN.

.

-

Banned

PM

PM