-

Banned

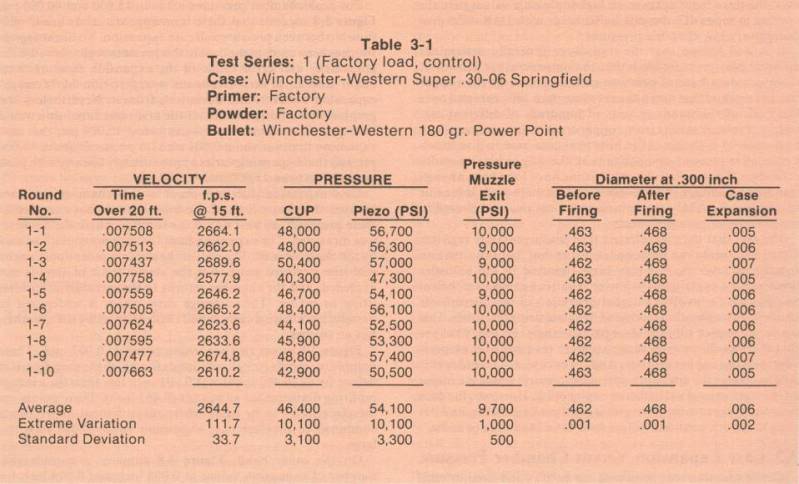

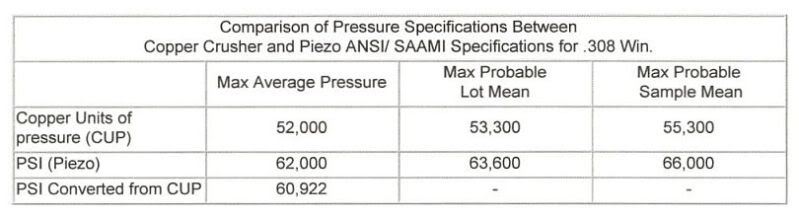

Max pressure for the .303 is given as 45,000 CUP or 49,000 PSI

If a 7.62X51 cartridge generates 52,000 CUP then it exceeds max pressure the Enfield rifle was designed to handle by 7,000 CUP.

If a .308 Winchester generates 62,000 PSI it exceeds the max pressure of the cartridge the Enfield was designed to handle by 13,000 PSI.

If a .308 Winchester is fired in a chamber proportioned for the 7.62 NATO it can have effectively .013 excess headspace, not wise with any high powered rifle.

Reloading Manuals give loads considered safe as possible to avoid accidents, they aren't authoritative on pressures of military ammunition under combat conditions fired in rifles that have seen decades of use and abuse, and which may have never been properly cleaned since leaving the factory 60-100 years ago.

I seriously doubt that the L42 Rifles were intended for use with the hottest 7.62X51 NATO available even then, much less the jacked up high performance ammo occasionally found on the surplus market, or ammunition degraded by several decades of storage under unknown conditions. The loads for the L42 would have been manufactured with accuracy in mind, and FN FAL ammunition of that time period was noted for its qualities.

I have a run down on barrel life of the Enfield rifling adapted to the FN FAL here. Extended barrel life was in large part attributed to the ammunition manufactured for rifle use at the time.

No manufacturer would try to sell .303 ammo loaded to 52,000 CUP or 62,000 PSI without a specific warning that it was not for use in Enfield Rifles . A P-14 might handle such loads if the rifle were in very good to excellent condition, but I doubt you'd find many who'd consider it wise even then.

. A P-14 might handle such loads if the rifle were in very good to excellent condition, but I doubt you'd find many who'd consider it wise even then.

No doubt if some owner of a Enfield converted to 7.62 has separated cases when firing .308 we will hear complaints about the quality of US cartridge brass rather than the differences in chamber dimensions.

That the .308 brass holds up in such an oversized chamber should be a testament to its quality.

-

06-24-2009 10:09 PM

# ADS

Friends and Sponsors

-

Legacy Member

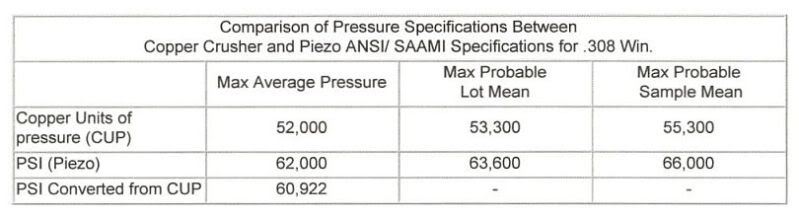

What is the SAAMI standard in PSI for proof testing the .308 Winchester?

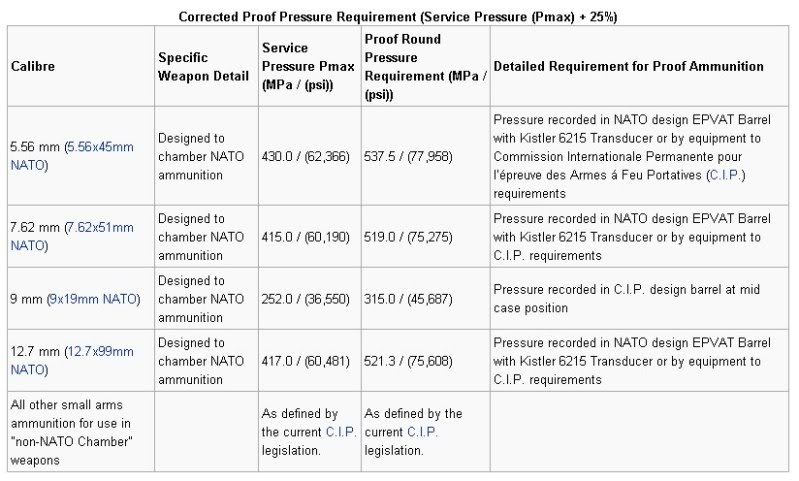

The 7.62X51 and the .308 Winchester are not proofed at the same pressures.

Is this fun or what?

-

-

-

Banned

-

I have an old friend who fought with the French in Algeria. Could put you in touch with him Ed. Although his contact list probably dates a bit

in Algeria. Could put you in touch with him Ed. Although his contact list probably dates a bit

-

-

Banned

From the article on the L42 found on this site.

5. I had some time on my hands today, so I dragged out ~Angel~'s two L42A1's from her collection. One is the very early 1971 conversion featured here in this

MKL

entry, while the other is a very late in the genre 1979 conversion (no photo montage as yet). It's interesting to see the changes in the markings and other conversion items over that 8 year time span.

Here's the pics and you can see they marked the "19T" and "crossed flags" clearly on the early 1971, exactly as Cotterill's article stated.

Since these rifles were proofed at only 1/2 Long Ton higher than the commercial proof for the .303 (18.5 T), is stands to reason they never intended the rifles to be used with the highest pressure 7.62 NATO or .308 Winchester cartridges available on today's market.

-

Legacy Member

Sorry Ed

SAAMI standard Section IV Proof Pressure Data by Transducer

for the .308 Win is 83,000 PSI minimum average to 89,000 PSI maximum average.

You can look it up on page 230.

Winchester designed the .308 Winchester. They are the final authority for the design.

That makes the US standards the final authority for the pressures and proofing of the .308 Win.

BTW I found the chamber drawing for the SAAMI proof testing and velocity testing chamber.

It has the SAAMI definitive basic gauge ring diameter and the head to shoulder datum dimension.

Last edited by ireload2; 06-25-2009 at 12:27 AM.

-

-

Banned

Take your shoes off ireload your math and facts need re-computing.

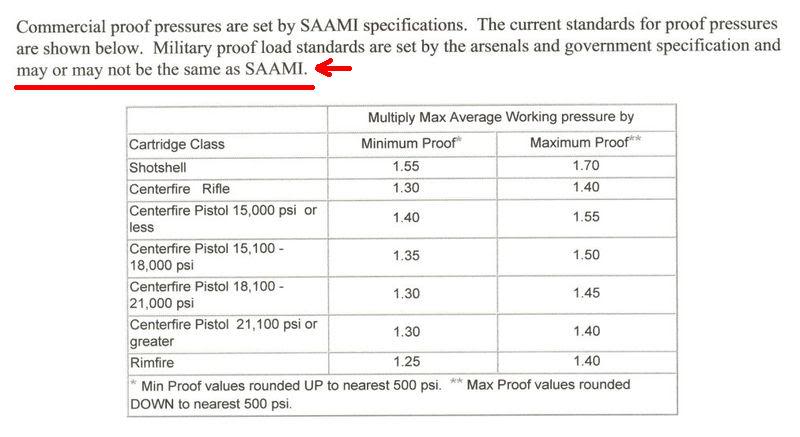

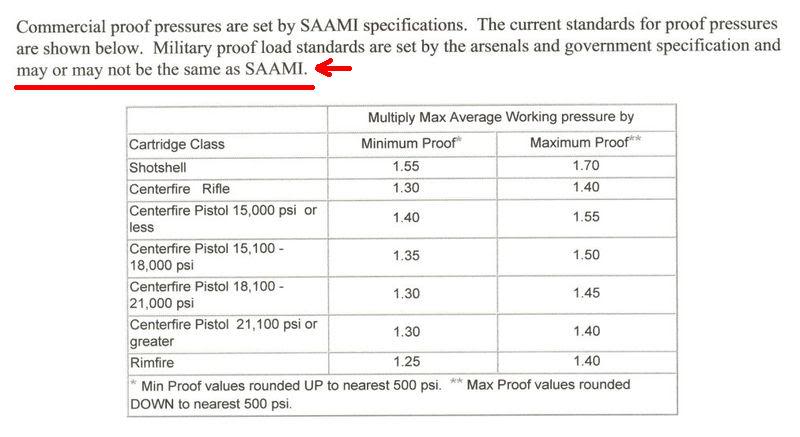

Proof pressure testing

CUP copper units pressure U.S. SAAMI

52,000 cup x 1.3 = 67,000 cup minimum

52,000 cup x 1.4 = 72,800 cup maximum

PSI piezo electric transducer method U.S. SAAMI

62,000 psi x 1.3 = 80,600 psi minimum

62,000 psi x 1.4 = 86,800 psi maximum

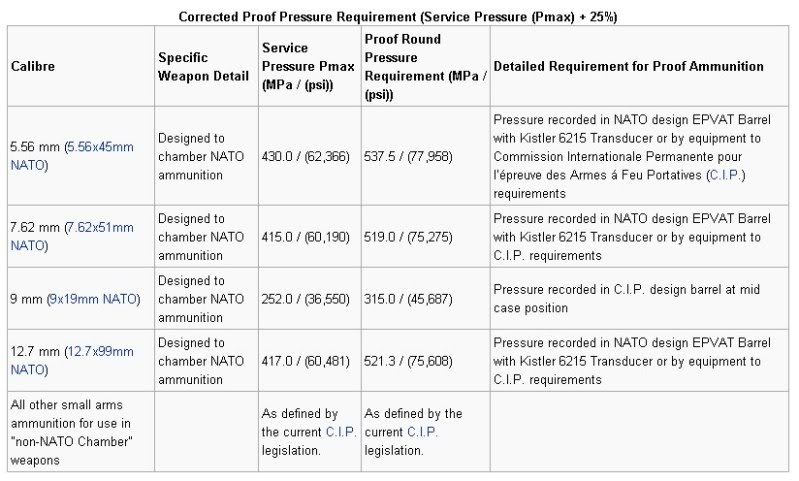

PSI piezo electric transducer method European CIP

60,000 psi x 1.25 = 75,000 psi

To make this simple U.S. SAAMI proof pressure testing is 30% to 40% higher than normal chamber pressure and European CIP is 25% higher than normal chamber pressure.

"Winchester designed the .308 Winchester. They are the final authority for the design. That makes the US standards the final authority for the pressures and proofing of the .308 Win."

Where do you get your Bovine Scat ireload2, nothing you have written here has been correct or has backed up with factual information. Or are you using the oiled cartridge case method with the increased dangerous pressures.

Winchester is NOT the final authority on proof pressure testing in the United States , the SAAMI sets the standards and NOT Winchester.

, the SAAMI sets the standards and NOT Winchester.

In Europe CIP sets the final standards for proof pressure testing, NOT Winchester or the SAAMI.

-

Banned

-

Banned

Max Chamber Pressure - SAAMI Specs

SAAMI Max pressure for the .303 expressed in PSI is 49,000

Max for the .308 Winchester is 62,000 PSI

Thats 13,000 PSI difference no matter how you cut it.

Figures for the .303 MkvII in CUP are generally given as 45,400 max, lowest CUP figure for US 7.62 NATO is 50,000.

Anyway you look at it a Enfield chambered for the .308 and firing high end ammunition would be subjected to the equivalent of a .303 proof load at every shot.

Firing the mildest 7.62 NATO ammunition the rifle would be sujected to increased stress well beyond the pressures of its original chambering. 7.62 NATO loaded for some NATO weaponry of today may well exceed the 19 Long Ton recomended pressures of the L42 Proof mark.

The No.4 Infantry Rifles were only authorized to use MkVIIIZ in emergency situations for good reasons, it's operating pressures were about those of most 7.62 NATO ammunition.

Australia also prohibited use of MkVIIIZ in rifles.

also prohibited use of MkVIIIZ in rifles.

There are lower pressure 7.62 loadings, including a Japanese load that is much like the Remington 125 grain managed recoil ammunition.

load that is much like the Remington 125 grain managed recoil ammunition.

155 grain 7.62 NATO target ammunition is said to perform poorly in converted No.4 rifles, perhaps due to added stress on the receivers.

PS

On page 186 of Reynolds "The Lee Enfield" he lists the P-14 rifle's ability to fire with a wet chamber as one of several reasons that it was superior to the SMLE and No.4 on the range. Firing with water in the chamber being common during wet weather shooting sessions. I guess they had so much rain in Britain in those days that they had no choice but to shoot in the rain.

in those days that they had no choice but to shoot in the rain.

He also wrote of experiments of firing oiled cartridges, Velocity increased and it was assumed there was an increase in chamber pressure but no damage to the rifles is mentioned.

-

FREE MEMBER

NO Posting or PM's Allowed

Originally Posted by

No4Mk1(T)

Simply put the design was adequately strong for the intended purpose.

That is the point me and Ed are trying to make nothing more.

Originally Posted by

No4Mk1(T)

No one has produced credentials showing degrees in Metallurgy and the engineering of firearms which I would consider as the minimum required to make a post in this thread and speak with authority.

I went to college for Tool and Die, and learned both in school and at work about the properties of metal, heat treatment and the selection of proper materials for the job and the abilities for metals to withstand excessive forces that they were not designed to do if that counts.

I say the 4% or so difference in pressure between the No.4 chambered in 303 British and the 308Win is not enough to worry about it. Actually its so trivial that if I was to mention this to anyone I know with decades of experience working with the properties of materials that they'd tell me I'm a idiot. Not a personal insult to anyone, just a fact. No design is within 4% of breaking or failing.

and the 308Win is not enough to worry about it. Actually its so trivial that if I was to mention this to anyone I know with decades of experience working with the properties of materials that they'd tell me I'm a idiot. Not a personal insult to anyone, just a fact. No design is within 4% of breaking or failing.

Originally Posted by

Alfred

Now I ask again , would any here load .303 ammunition to 62,000 PSI and sell it as safe for use in No.4 rifles?

No one would, that is being stupid, look at your reloading manuals I doubt any 308Win max load will reach 55,000PSI. Now look at that same reloading manual where the Winchester Short/Super Short Mags and the Ultra Mags are listed as 62,000PSI loads.

Dimitri

Last edited by Dimitri; 06-25-2009 at 03:15 AM.

. A P-14 might handle such loads if the rifle were in very good to excellent condition, but I doubt you'd find many who'd consider it wise even then.

Register To Reply

Register To Reply