-

I gotta agree w/ Mr. Horton re the WW brass, its about worse than nothing if you want any kind of peace of mind whislt pulling the trigger! It was also with which I started reloading 303 back around 1979/80 and it hasn't gotten a whole lot better. Probably have 200 new unprimed cases gathering dust somewhere.

They can be cut into shiny spoons w/ a bit 'o cutting and hammer forming, but I mostly fly fish bluegill w/ popping bugs and only VERY small pieces of brass will float!

-

-

08-03-2009 08:42 AM

# ADS

Friends and Sponsors

-

(Deceased April 21, 2018)

Mr Horton, it's rather obvious that in a roundabout way , you have decided to tell poor old stupid me that rim thickness on a 30-40 Krag and U.S. made .303 cases is the same.

and U.S. made .303 cases is the same.

NOW TELL ME THAT THE RIM THICKNESS ON COMMONWEALTH BRASS IS THE SAME AS A 30-40 KRAG !!!!

That makes me wonder a bit why target shooters on the other side of the pond bothered to use RIM THICKNESS GAGES.

I really don't mind you imparting your knowledge on the subject which is obviously extensive, but I wish you would desist from those patronizing replies.

-

Advisory Panel

Please lads, keep cool!

I have just looked up the CIP dimensions for the 30-40 and the .303

The rim thickness AND tolerance dimensions are IDENTICAL for CIP.

Thickness R = 1.63 mm tolerance -0.25 in both cases.

So you may reasonably expect modern commercial examples of both types to have identical rim thicknesses.

This is, however, no guarantee that military cartridges have the identical dimensions.

Perhaps someone would care to check the SAAMI dimensions?

Patrick

-

-

Advisory Panel

P.S: I expect you have all worked out by now that a negative tolerance of 0.25 mm is a gnat's whisker under 10 thou. Which means that all idea of holding a 3 thou head clearance is pointless unless you select the cartridges for rim thickness - which is why a rim thickness gauge seems to be a good idea.

Patrick

-

-

Banned

-

Advisory Panel

SAAMI rim thickness specs are, indeed, the same for .303 British and .30/40 Krag

and .30/40 Krag - .064" -.010" (in other words, maximum .064", minimum .054"). Reference: Handloading, NRA, 1981, pp. 277, 279.

- .064" -.010" (in other words, maximum .064", minimum .054"). Reference: Handloading, NRA, 1981, pp. 277, 279.

I suspect a bunch of the confusion on such topics starts when somebody measures a few cases and concludes they're all just like those few - forgetting reasonable tolerances allow mass-producing these little brass bottles for a few cents each. My personal experiences with Winchester .303 cases, for example, are very different from Ed Horton's - leading me to conclude that Winchester's quality has varied from time to time, but hardly justifying blanket condemnation or praise of all W-W .303 brass.

Drawing broad conclusions from small samples seems to be a frequent characteristic of internet firearms discussions. (But, I'm basing this conclusion on a fairly small sample, too!)

-

Thank You to Parashooter For This Useful Post:

-

Banned

Parashooter

Let me differentiate our conclusions on Winchester cases, my Winchester cases were fired in a dry oil free chamber and your Winchester cases were fired after being oiled.

Drawing broad conclusions and making comments when you didn’t mention the fact about your lubricated cases negates any comments you made above about the different results.

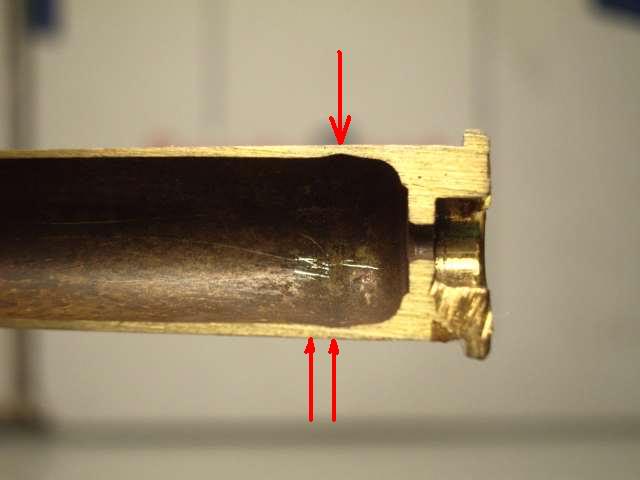

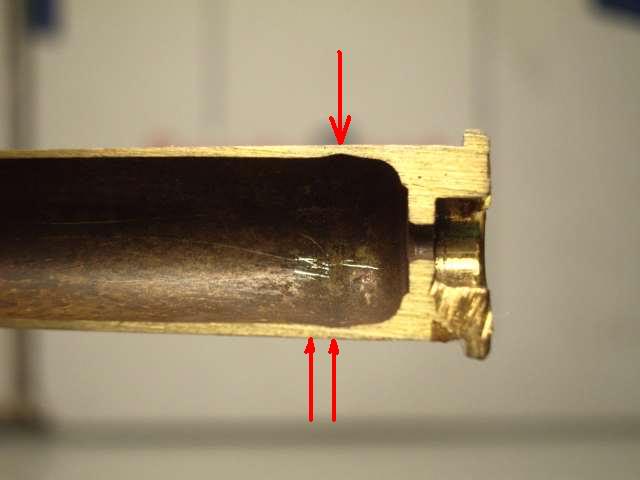

The factory loaded Winchester case below was fired in a dry oil free chamber with the headspace set at .067 and the case stretched over .009 thousandths. I would never dream of firing fully loaded factory ammunition with oil on the cartridge when the bolt thrust would be doubled on the bolt face on any Enfield of mine.

As I said before Parashooter you can’t have it both ways, oiled proof cartridges are used to seat the bolt head and the bolt lugs on the Enfield Rifle . The single oiled proof cartridge seats the bolthead and bolt lugs by not gripping the chamber walls and applying twice the force or bolt thrust on the bolt face as a dry cartridge.

. The single oiled proof cartridge seats the bolthead and bolt lugs by not gripping the chamber walls and applying twice the force or bolt thrust on the bolt face as a dry cartridge.

After the Enfield was proof fired the headspace was checked with a .067 headspace gauge and if the bolt closed on the .067 gauge the rifle failed proof firing. This should indicate to anyone that oiled cases doubles the wear and cuts longevity of the rifle in half.

Our internet firearms discussion on Winchester cases is pointless due to different “testing” methods and sampling sizes mean absolutely nothing when the “test” shooting is not conducted under the exact same conditions.

We will continue to agree about disagreeing on oiled cartridges and methods so please be kind enough next time to inform everyone I’m reloading and shooting Oranges and you are reloading and shooting Apples.

-

Advisory Panel

Your memory is failing, Mr. Horton. As I reported here, the first test with my Winchester cases was totally dry. Case separated after 10 shots with moderately heavy loads. I consider this acceptable performance - and no oil or other lubricant was involved.

-

-

Legacy Member

My questions are.

1 when the case grip in the chamber has been removed [ lubed case] the case life extended [10 failure to 35 and ongoing] what life expectancy does the bolt lugs now have as they are carrying all the load not sharing it with the case.

2 Is case life more important than a non replaceable part. Cases are a consumable.

3 The dimensions of a battle rifle are and will allways be different to a commercial one the 303 is probably the worst offender, can not that be accepted.

-

Thank You to Bindi2 For This Useful Post:

-

Advisory Panel

Originally Posted by

Bindi2

The dimensions of a battle rifle are and will allways be different to a commercial one the 303 is probably the worst offender, can not that be accepted.

I can accept that!

Really, the problem isn't three thou at the rim, its the forty* thou longer at the shoulder! If you measured headspace to the shoulder of a .303 chamber, you'd pull the barrel off, turn a thread off the back, and re-fit it after cutting a match dimension chamber. Anything short of that is still doing bugger all to improve the life of any case.

BTW, Ed... I scored another thousand HXP's the other day...

(* dimension picked form thin air- can measure it if needed, but it won't be far short of that)

-

PM

PM