-

Legacy Member

Originally Posted by

NC_Xplorer

Hello everyone,

I shot my No.4 in a

CMP

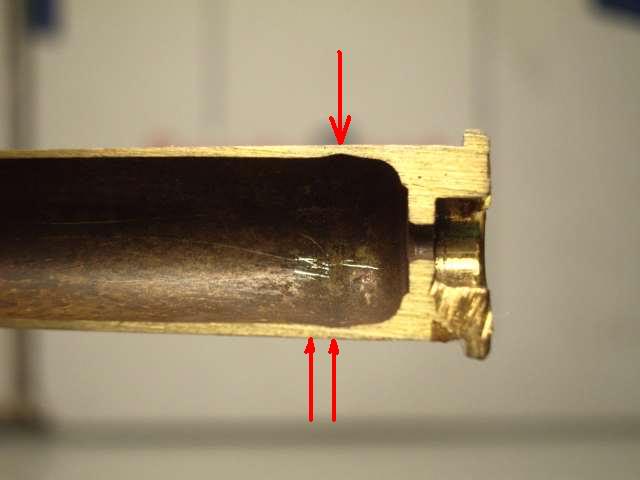

vintage rifle match on Saturday and I was using new reloads that I had worked up using new brass. I experienced multiple cases with visible splits about .125 to .250 above the rim and at least 3 complete head separations. My Enfield is fitted with a #3 bolt head. From my research on this forum I have concluded that I have excessive headspace issues. Will this require a gunsmith to fix or is there another solution? I know from reading a copy of a manual that was posted here that I have the largest bolt head already. I don't think switching to a lower numbered bolt head will fix this. Has anyone else had a similar problem like this?

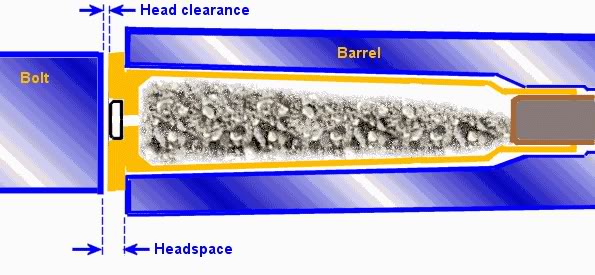

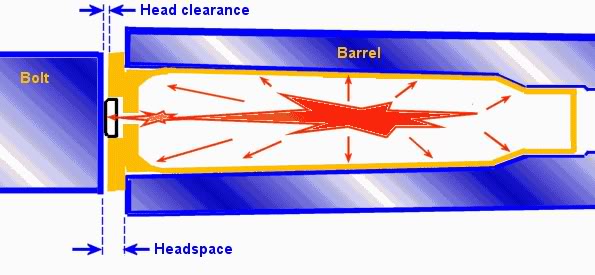

This is not a headspace problem. Your cases are too small for your chamber. The case is lying in the bottom of your chamber held firm by the bolt on fireing the case expands more to the unsupported side causeing head separation at worst. Solution 1 use a fireforming light load or add a O ring to the case to centre it in the chamber before fireing. Get better fitting cases or better quality ones. Do not mess with the bolt untill you are 100% sure it is not the ammo

-

-

10-26-2009 01:26 AM

# ADS

Friends and Sponsors

-

Banned

To expand on what Bindi2 said above, a chain is only as strong as its weakest link and the weakest link here is shooting American made .303 cartridge cases. Our American made commercial .303 cases are designed to shoot in rifles with smaller diameter chambers that have less head space than military designed rifles.

On top of this American made .303 ammunition must be safe to shoot in oldest Enfield's still being shot today. The chamber pressure of the original British .303 smokeless cartridge was 17 tsi or 17 tons per square inch which was later upgraded to 18 tsi and then 19 tsi. These pressures convert to 38,080 CUP, 40,320 CUP and 42,560 CUP respectively. http://www.gordonengland.co.uk/conversion/pressure.htm

.303 smokeless cartridge was 17 tsi or 17 tons per square inch which was later upgraded to 18 tsi and then 19 tsi. These pressures convert to 38,080 CUP, 40,320 CUP and 42,560 CUP respectively. http://www.gordonengland.co.uk/conversion/pressure.htm

The bottom line here is that Lawyers working for the American firearms industry help design the .303 British cartridge case and the factory chamber pressures are kept below 43,000 CUP. The standard rated pressure for the .303 British is 46,000 CUP (copper crusher method) or 49,000 PSI (transducer method).

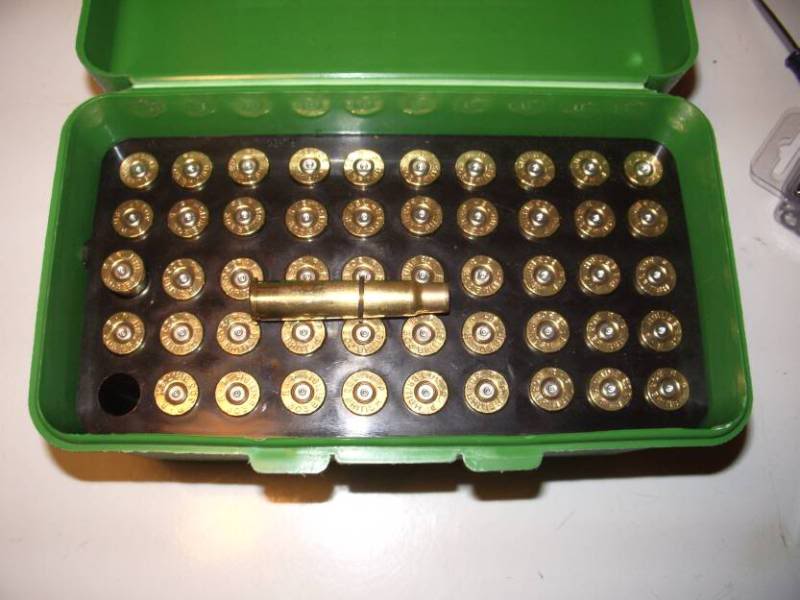

Below are two fired .303 cartridge cases, on the left is a Prvi Partizan case and on the right is a Greek HXP case. The Serbian made Prvi Partizan case on the left has a larger base diameter than the Greek military HXP case which shows how much the case expanded to meet the chamber walls.

The only cases I buy today are the Prvi Partizan cases because they are made to a higher standard than American made cases and are .010 thicker in the base web area.

Below is a once fired factory Winchester case fired in my 1943 Maltby with the head space set at just under .067, this case has stretched and thinned .009 (nine thousandths) in the base web area.

The second time these cases were reloaded and fired.

Your Enfield "might" have a head space problem, it might also have a large diameter chamber and last but not least it might be suffering from weak wimpy made American SAAMI cases. When it comes to the .303 British I do not believe in the fault finding terms of “inherent weak design”, “rear locking lugs” or any of the other garbage you hear about the Enfield Rifle . I have been reloading a Winchester 30-30 with rear locking lugs for over 30 years and NEVER had a single case head separation.

. I have been reloading a Winchester 30-30 with rear locking lugs for over 30 years and NEVER had a single case head separation.

The only difference between my 30-30 and the British Enfield is the chamber pressure the cases were designed to withstand when fired.

Check your Enfield's head space as a starting point and test fire Remington factory loaded ammunition as a base line test for case head separations. Remington made cases are the thickest of our American made cases and are loaded to lower chamber pressures than reloaded ammunition can be.

-

-

Legacy Member

The design of the Lee-Enfield chamber and ammunition is problematic.

When the chamber is at it's largest (minimum material condition) and the brass is at it's smallest (minimum material condition) the clearance between the case and the chamber is about .012 at the case head. In actual use the difference is about .010. This is about 2X what is found with other infantry cartridges.

In addition the Lee-Enfield standardized chamber has a shoulder that looks nothing like the ammo and the chamber shoulder can be as much as .067 forward of the shoulder of the ammunition. This promotes stretching of the brass also.

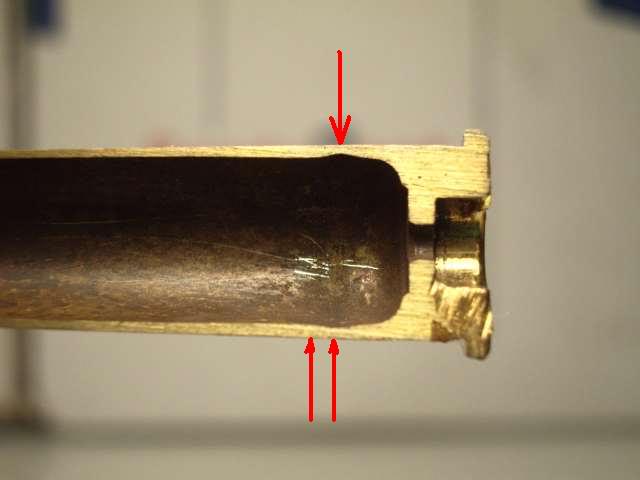

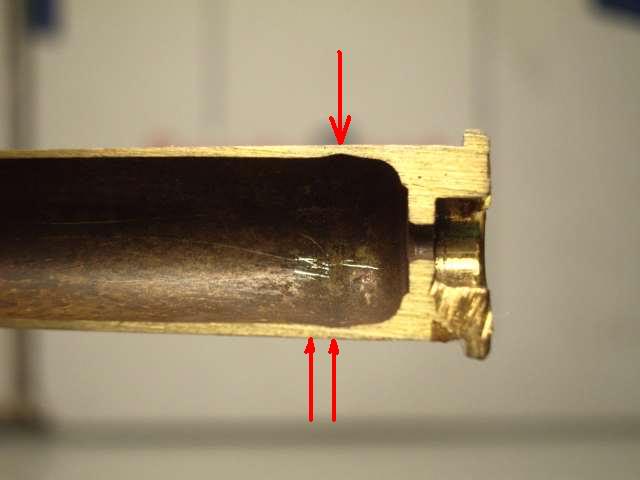

While there are variations of head space they are minor in comparison to the engineered in clearances between ammo and chambers. These clearances combine with the springiness of the rear locking Lee-Enfield design, which dates back to the black powder era, to promote stretching of the case head at the junction of the solid head and the case walls. Insuring there is minimal stretching of the case head on the first firing will improve case life regardless of the actual measured headspace of the rifle.

Last edited by ireload2; 10-27-2009 at 03:07 PM.

Reason: rampant typos

-

-

Banned

-

Y'all need instant replay on this topic.

-

-

Banned

Originally Posted by

jmoore

Y'all need instant replay on this topic.

Instant replay is eating grits and okra for dinner when you already had grits and okra for breakfast.

-

Sounds good! Grits and okra- do it again!

No, really. You should have an Enfield headspace and chambering Sticky.

ETA Ok, there's already a headspace sticky (maybe could use additional input?), so a L-E 303 brass and chamber systems thing. W/ charts and data and computer graphic coolness.

Mr. Laidler states "Don't over CHS", which is fine, except for us knotheads that will reload any old piece of brass found at the range. (I've about quit that habit, except for pistol brass, excepting AMERC brand! (lots of exceptions, eh?)) Parenthectically speaking, I am. Oy!

states "Don't over CHS", which is fine, except for us knotheads that will reload any old piece of brass found at the range. (I've about quit that habit, except for pistol brass, excepting AMERC brand! (lots of exceptions, eh?)) Parenthectically speaking, I am. Oy!

Last edited by jmoore; 10-27-2009 at 05:06 AM.

-

-

Banned

-

Advisory Panel

Originally Posted by

Edward Horton

If you do further searching on head space you will find Thunderbox in the

UK

and Son in

Australia

think Americans have “head space phobia”. If you dig even further you will find out both Thunderbox and Son reload Greek HXP cases and don't have any head space problems.

Hey, Mr Horton... I have stopped reloading HXP cases for now. I got another box of twelve hundred HXP89 to empty out before I reload them.

I will be doing all my initial firing with the o ring fitted from now on also. Even though "head gap" isn't a major issue with the HXP cases, and true- I have some that have been reloaded to MkVII specs 6 times, with two light FLR's, (usually on the third reload and the fifth to keep them from being tight to chamber) and neck sizing in between. I have a couple of chambers that do leave the cases showing a stretch on one side at the web. Centering and fireforming will most likely delay even further the eventual head separation that I still haven't had.

Thumbs up for all the info here so far

-

-

Legacy Member

If the so called "undersize" US made brass is used on a different application such as the 6.5X53R Dutch M95 turnbolt Mannlicher (with the front locking arrangement identical to a Mannlicher-Schoenauer) the US made brass will give normal life. Normal life meaning it can be loaded to full power ballistics and it will last until the primer pockets wear out from pressing primers in and out. I would point out that the M95 Dutch Mannlicher design is a contemporary design of the original Lee-Enfield

and is much older than the #4 Lee-Enfield. One way to increase the life of brass in the Lee-Enfield is to purchase or form brass with case heads at least .455 in diameter. If you can find brass as large as .458 it is even better since is is likely that your chamber just ahead of the rim actually measures .460 to .462. This is an as designed condition. As designed the brass can actually be as small as .450. Combining the maximum chamber with minimum brass stretches the case head at the web diametrally when fired.

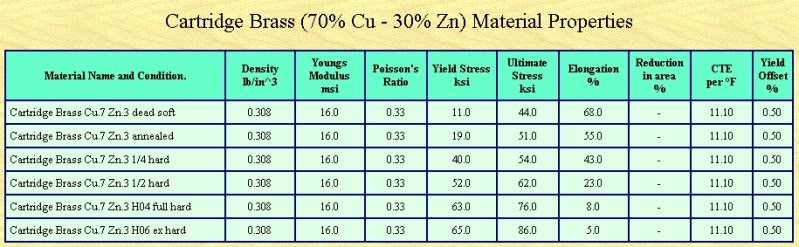

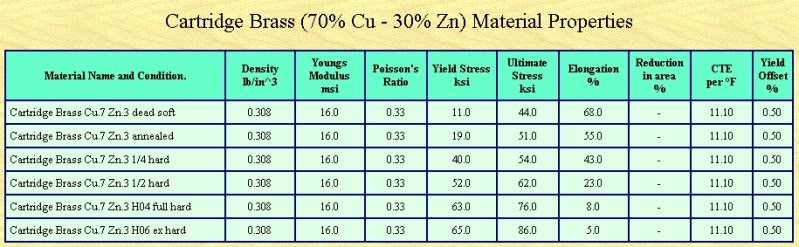

BTW the chart below is nothing more than the different tempers of the exact same material 70-30 cartridge brass. The various tempers are developed by cold working of the material or by annealing cold worked material back to a softer temper. Typically the case head will be of a harder temper. Since it is desirable for the neck of the case to be more ductile it is annealed back to one of the softer conditions.

Last edited by ireload2; 10-27-2009 at 03:24 PM.

-

PM

PM