Regarding barrel proof, refer to page 12:

(g) Proof. - The barrel will be submitted with the action attached for proof. The distance from end of bolt to face of barrel will be tested with a cartridge head gauge .067-inch. The proof will then be carried out with a proof cartridge, the charge being about 33 grains of No.3 cordite, having a service bullet of 215 grains, giving a mean pressure not below 24 tons per square inch, after which the action will be examined; and the barrel, body, and bolt head will be marked with the proof mark."

Alan thank you for posting the above information, more of the Enfield puzzle is coming together. In my collection of Enfield data it stated that if the bolt closed on a .067 head space gauge after firing the proof test round, the rifle failed proof testing due to excess bolt setback. An oiled cartridge DOUBLES the force placed on the bolt when firing a cartridge.

24 tsi (tons per square inch) equals 60,000 CUP to 65,000 CUP in American radial copper crusher proof pressure testing methods with an oiled proof test cartridge.

18.5 tsi or normal operation cartridge pressure = 46,000 CUP (American pressure testing method)

Cartridge Pressure Standards

"In Britain, a third set of crusher standards were developed, using a "base" crusher. The crusher was a short, thick tube placed behind a piston at the base of the cartridge, and the firing pin passed through the center. The cartridge case was well oiled before firing, to minimize cling to the chamber walls (if not oiled, the indicated pressures were about 25% lower). To prevent case rupture on set back of the base, the crusher was first deformed in a press to a pressure a bit lower than that expected in firing. The units were generally stated in British long tons per square inch, or tsi. Pressures indicated by this method run 10 to 20% below those indicated by radial crushers.(U.S. testing method) Kynamco in Englandstill rates their production cartridges with this method. (axial or base crusher method)"

British long ton multiply by 2240 plus multiply again by 1.1 to .1.2 to convert to American copper crusher pressure figures.

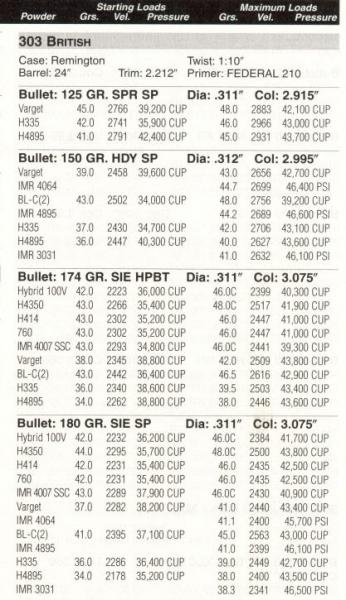

Below, ever wonder "why" American .303 cases fall apart when loaded to over 43,000 CUP? Hodgdon, Remington, Winchester pamphlet reloading pressures figures.

I call this the “British Axial Enfield Inch”

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

Register To Reply

Register To Reply