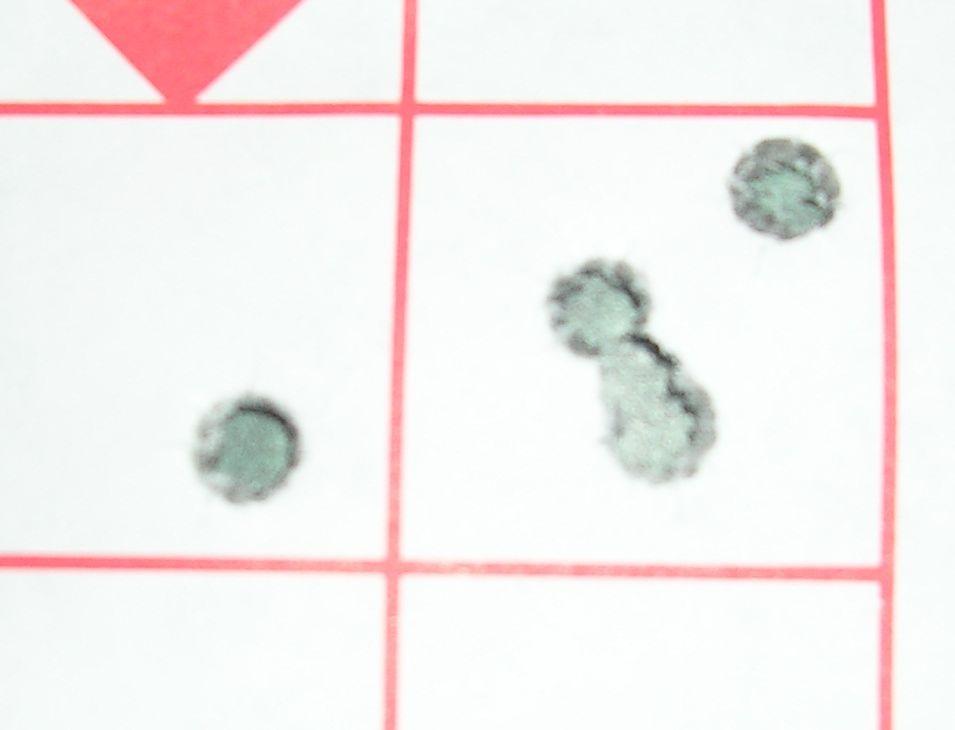

I don't know where your info comes from but all I have read says if used correctly it works very well. I have done a 1910 03 that was a black hole and after rethroating, shot .311 jacketed bullets 5 into 2", next was a Nickle steel 03 sporter rebarreled with a 4 groove 1941 remington barrel and redone to 300 Win Mag. Was sold as a NG barrel. After a good cleaning, all that was wrong was very light frosting 3" back from the muzzle. 10 rounds with the 1200 grit brought it from 5 in 2" to 5 in 1". My Swede speaks for itself. All the cleaning in the world would never have evened out the bore diameter. Although the grooves are still a bit dark, a dry patch pushes end to end with even resistance. Many of the finest barrels made since rifling was invented have been lapped. The only disadvantage was that each end had to be cut back as the lapping process tends to bell each end slightly. Fire lapping avoids that problem. Its only downside is that when using lead bullets, it tends to extend the leade a bit. Hardly a problem in a 96, as the leade is already a mile long.

I decided to give it an old fashioned cleaning with Copper dissolver, followed by dry patches. then Hoppes on a bronze brush, more dry patches, Wipe Out and more dry patches.

Last patches had just a trace of gray. Now I'll retry that 4350/AMax load and some 130 TSXs as well. It may just go speed goat hunting Information

Information

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current.

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

Register To Reply

Register To Reply