I feel better now.

I got a complete bolt assembly in from Numrich.

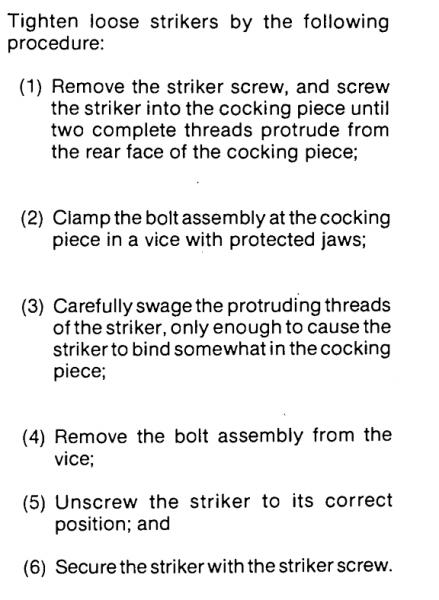

The bolt wouldn't slide in at first. I noticed the bolt head wouldn't turn enough counter-clockwise to slip into the receiver. It was very tight, but I managed to unscrew it. Using 600 grit wet/dry sandpaper I smoothed the flat areas where the bolt and bolt head meet, then finished it off with 1500 grit. The bolt head lined up perfectly.

Took her to the range and it funtions great.

Lotta work to get a gun to go 'bang.'

Also ordered an issue WWII Enfield sling. My gun is a 1943, and the sling I got just happened to be dated 1943. Sweet!

PM

PM