DISCLAIMER: Stencollector has been kind enough to allow me to post and use his collection of material on building his SAS3 Sten, the actual gun used to get RCMP approval. The following is his work.

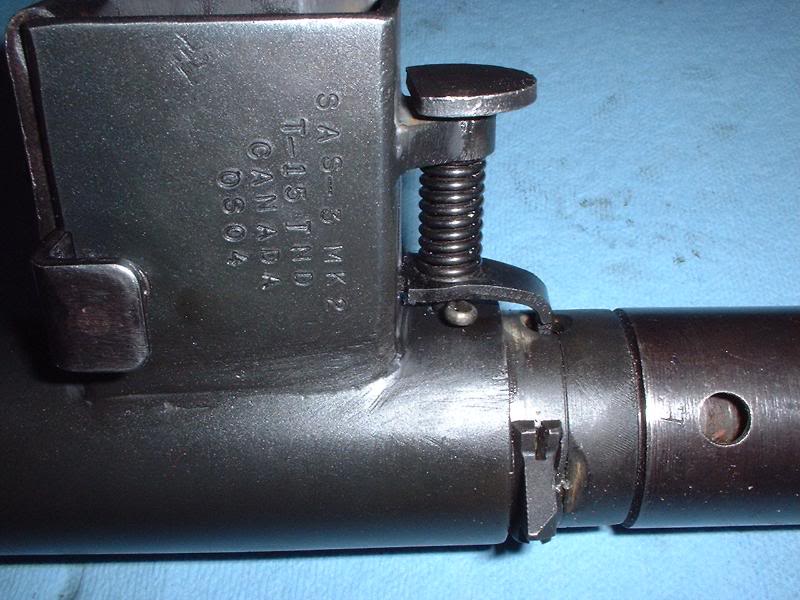

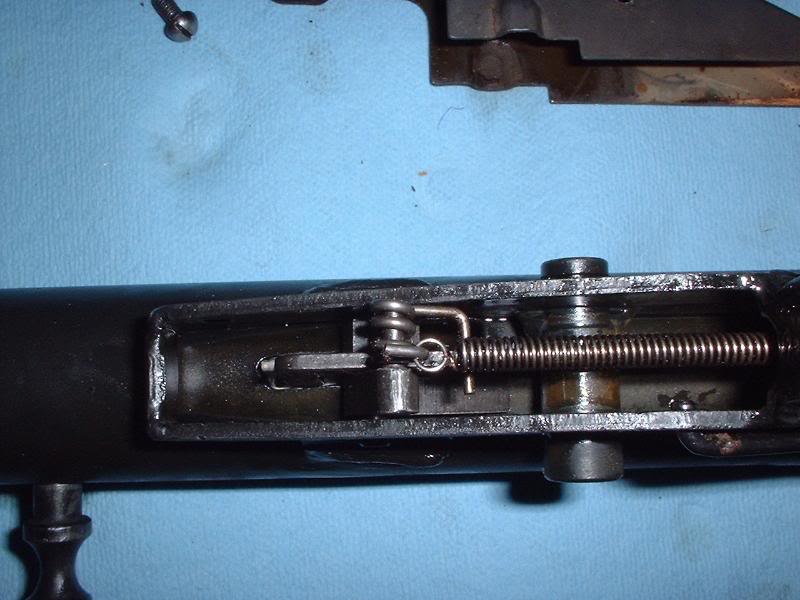

Here are the final photos of Stencollector's project. Photo 1 is of the dovetail filed in to the receiver. Photo2 is of the two main items with the trigger housing welded back on before refinishing. Photo 3, is of the components ready for assembly. Photos 4, 6, and 7 are the serial numbers located on the magwell, the trigger housing, and the tube. Photo 8 is a shot of the semi auto closed bolt system, which utilizes a AR-15 type firing pin. Photo 9 shows the trigger mechanism from underneath. The change lever has been welded from the top (before it was welded to the receiver) and the slot for the disconnect is cut so it does not allow any side-to-side movement. Any altering of the trigger mech to try and make it F/A will jus result in the gun jamming, as the round will not slide over the firing pin. The bolt was not built with feed lips like that of a normal sten.

Photo 12 shows the addition of metal to the barrel lock. Because the magwell was moved back 1/16" on the magwell collar, the barrel lock had to also be extended.

The remaining photos are of the finished product.

Information

Information

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current.

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

PM

PM