-

Legacy Member

Originally Posted by

fjruple

Cplstevennorton-- I deeply appreciate your postings of the M1917 cracking issues. And the parts of documents on the initial 250,000 M1917s to the

UK

. I am just a details-type guy and like to solve "mysteries" questions about cracking issues. Have you run across any detailed studies by the US Ordnance department on the cracking issues. You have posted the results themselves via the major command letters on the issues. I am looking for details such as Serial numbers, were they part of a rebuild program with JA or SA barrels or original barrels. Have you run across any documents from the Columbus General Depot itself? I would be interested in seeing a copy of a photo copy of an original letter from Columbus. One last question have you run across any documents on the M1917 rebuild contract by the Wright Corporation in Dayton, OH. Please keep posting!!

Thanks

--fjruple

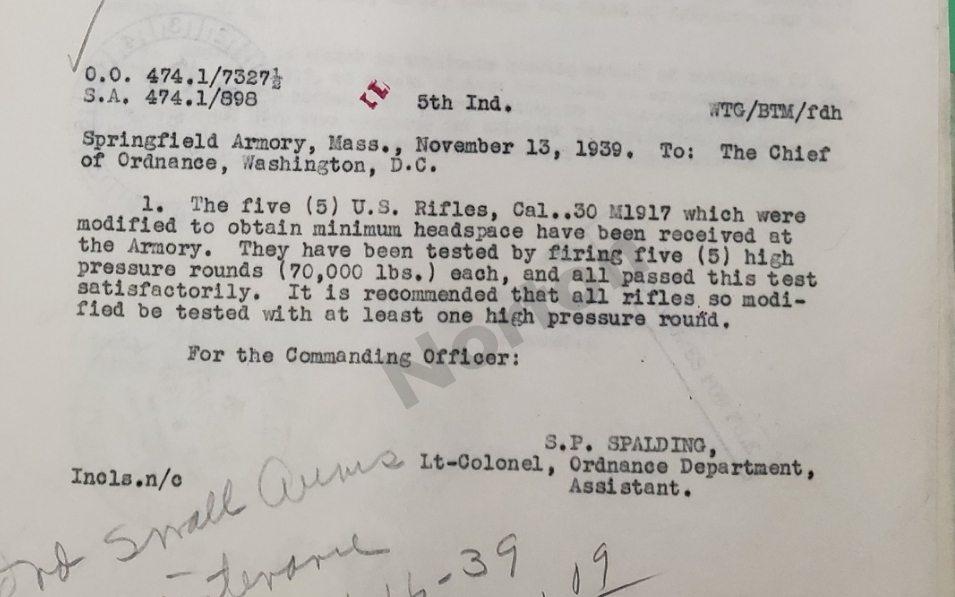

I have not pulled the Army files on standard rifles previous to 1946 as of right now. Except for sniper docs. I have all pulled all sniper docs from the Army back to around 1900. I have mostly focused on the Marine Corps documents, but have been branching out lately.

This week I'm at the Archives and will be pulling documents from the army prior to 1946, so maybe I will find more on this. Andrew has been digging in the WWI docs and has found evidence there might have been heat treatment problems with some M1917's.

The info from the Columbus Depot was in a report of lend lease activities that I pulled to document the Lend Lease Garands.

Thank you for the kind words. I will certainly keep a look out for this at the archives. My hunch though, they were in 1919 making the M1917 limited standard, which means it was a backup. I suspect they might have seen problems with them in WWI, but never did anything about it, because in 1919 they for the most part weren't using them anymore.

Well most sat in storage, then in WWII they were sold to foreign countries and issues with the receivers came out again.. That is my hunch.

---------- Post added at 05:32 PM ---------- Previous post was at 05:27 PM ----------

Originally Posted by

Ridolpho

cplsteve: There is a slight inconsistency between some of these memos. The memo in post#1 (RIA) says that they can't strip and examine all ERA rifles because costs would be prohibitive. Yet the letter in post #4 (slightly earlier) quotes other documents that suggest that of 26,000 rifles "issued by the Colombus depot for sales, that about half were returned due to cracked receivers". Does this mean that 26,000 rifles were detail examined and one-half found cracked? If so, who did the examination? it would have to be a major facility and that many rifles with cracks would have been a discovery of monumental importance. I would suggest it is more likely that a spot check of a sample found some cracked receivers, perhaps all in ERA rifles and that led to the ERA rifles being returned. The later memos show a frequency of cracking much lower than that implied in the comment about the 26,000 rifles. But the frequency in the detailed exams is still troubling although lacking in specifics about the individual rifles (like were they re-barreled).

Source document studies are very important but not all info was recorded and much has been lost. A useful adjunct to this would be a forum survey asking owners of M1917's who have examined rifles in detail to mention instances of cracked receivers with details of manufacturer and whether or not the gun has definitely been re-barreled. Conclusions drawn from old documents still have to be vetted against reality. This thread (and the one on Gunboards) is leaning in the direction that original Eddystone M1917's are prone to receiver cracks whereas numerous threads from the past (based on exam of rifles) would appear to me to contradict this. The whole issue is of importance to owners of ERA rifles as a blanket determination of susceptibility to cracks might affect their value.

Ridolpho

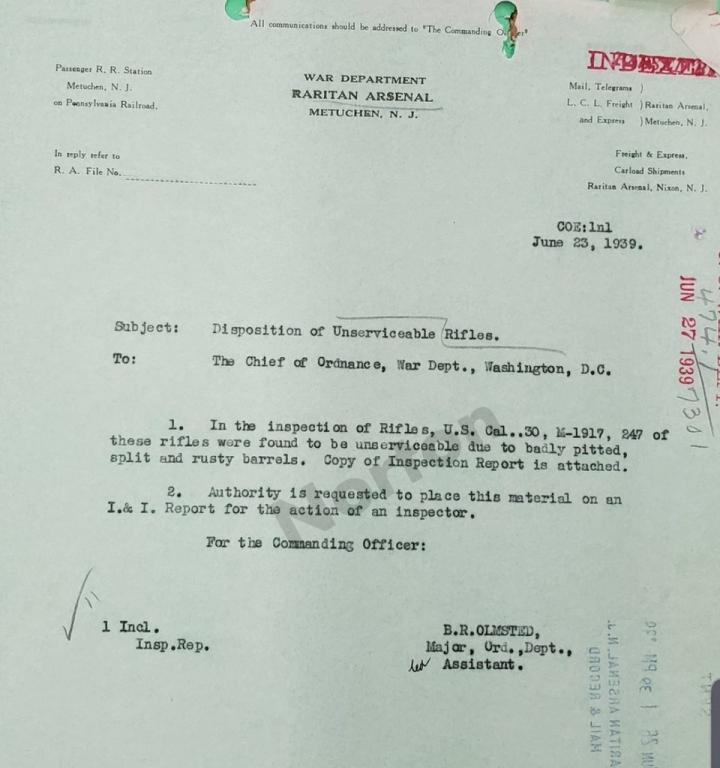

No, Columbus Depot did not check the M1917's before sale. It does mention that in the other lend lease files. The rifles were in storage since WWI, and were just shipped. So they did not check them. The only ones checked were the 230 that RIA had pulled and checked.

With documents, I have found it's important to put cliff notes and in order, it helps a lot to understand what happened.

Undated, but Prior to May 1947, Columbus Ordnance district had sold 26,000 M1917's. About half of this number were returned to them because of cracked receivers.

May 26, 1947 Because they have heard of the problems at the Columbus District, RIA tells Army Ordnance that they had pulled 30 random receivers and checked them. Of the 30, 4 were cracked. They basically ask Army Ordnance what do we do with them.

June 24, 1947 Since May 26, 1947, RIA had continued to check receivers and have now examined a total of 230 Receivers. Of those 18 were cracked, and 3 had cracked barrels. They are telling Army Ordnance it is too time consuming and expensive to check all of these receivers. They recommend to Army Ordnance it's better to just state all eddystones should be used for drill or blank firing only.

July 15, 1947 Army Ordnance replies to RIA that cracked receiver eddystones will be sold with a note saying they are for drill or blank firing only.

-

-

07-28-2019 05:32 PM

# ADS

Friends and Sponsors

-

FREE MEMBER

NO Posting or PM's Allowed

Same this is the sky is falling on CMP . My same response here.

. My same response here.

Wow, shocked shocked that one of the primer sources on the 1917s in actually working on them was not even brought up, AKA Chuck in Denver AKA Warpath.

My take is this is not remotely solid. Nor backed up by facts.

One of the first ones was that WWI ammo was highly suspect and quality control was poor. Suddenly production went form nothing to 100s of millions of rounds. If fact bad ammo was one of the key issues with the 1903s.

Chucks experiencing is that Eddystones had fewer cracks than others. Any cracks were due to the use of the wrong tools.

We have pictures of the plants in WWI and they DID NOT use pneumatic tools.

As there is a witness mark, even if they had done so you took to to the WM and stopped.

Wrong tools and corrosion is going to make it an iffy proposition.

As for head space, these are being mis-charactrized there as well. They were battle rifles. It is standard for the head space to be long.

The biggest issue with head space is a case that is no longer usable. The Military did not care about re-using cases. They did care about them working when fouled.

There were no SAMMI specs then.

I have had something around 12 of these and I don't know how many more I have looked at. None were cracked, all shot fine.

These were commonly used as a basis of a cartridge change to larger calibers.

The steel used was Nickel Steel, not the standard steel (1903 went to that 1920 or some such). Its got more stretch.

And how many millions of P14 and 1917s were made? 5 million? How many 1903s ? there was a reason 75% of the troops were issued 1917.

So, 3 out of 4 rifles were 1917. Begin to get the picture?

I had one that had a 1917 barrel put back on (different mfg) done with a pipe wrench, thread cut and it still shot fine (they didn't get the chamber quite right) - I broke it down and sold it as was and kept the stock (nice R) - it in fact had a short head space that I got a bolt given to me that was wrong and worked in that rifle.

Any rifle that has an unsupported head has a possible problem, any mil surplus rifle has a possible issue and you need to check it out, but there is nothing specific to the 1917s let alone Eddystone that was other than one off failures that occurred.

Lets keep the rumors and innuendo out of this.

-

FREE MEMBER

NO Posting or PM's Allowed

Source document studies are very important but not all info was recorded and much has been lost. A useful adjunct to this would be a forum survey asking owners of M1917's who have examined rifles in detail to mention instances of cracked receivers with details of manufacturer and whether or not the gun has definitely been re-barreled. Conclusions drawn from old documents still have to be vetted against reality. This thread (and the one on Gunboards) is leaning in the direction that original Eddystone M1917's are prone to receiver cracks whereas numerous threads from the past (based on exam of rifles) would appear to me to contradict this. The whole issue is of importance to owners of ERA rifles as a blanket determination of susceptibility to cracks might affect their value.

Chuck in Denver has seen hundreds. I have seen 20 or so that were CLOSELY examined - none cracked . Chuck a few Rem and Win than E cracked (not sure he has seen any).

Regardless, E was better than twice the numbers of R or W. 50% chance the rifle you choose to convert or re-barrel was an E.

And they went through a process to store, how often that involved taking a barrel off even if it was put back on?

And tens of thousand were re-barrled to JA, HS or RIA in WWII.

-

Contributing Member

Things to consider. The 1917 has known cracking issues from re-barreling. This report is dated 1947, post WWII and post nearly all re-barreling of 1917's. It does not distinguish from re-barrels and those with original barrels. Most were re-barreled. when I purchased my first, it was a re-barreled Eddystone and I went over it with a fine tooth comb. I also did the acetone test to check for cracks. No problems. My second Eddystone still has the original barrel. I don't recall if I did the acetone test on that one but I'm not especially concerned with it. It went through two wars with that barrel and receiver.

-

-

Legacy Member

-

Thank You to cplstevennorton For This Useful Post:

-

Legacy Member

-

Thank You to cplstevennorton For This Useful Post:

-

Contributing Member

I remember reading a letter from a "Remington" official complaining to a US Army Ordnance captain about quality of the steel they were getting for the M1917. I don't know if the "Remington" official was representing both Remington Ilion or Eddystone or both locations. I cannot remember if the document was from the Cody Museum, lots of M1917 documents, as they were part of the rifle production board or a foot note in one the books on the M1917. At the time I though it was interesting since the Army Captain response was to blow off the "Remington" official. As we know from experience that usually comes back to haunt us with future problems. I am deeply interested in the cracking problem and am looking in the weeds from the problem.

-

Thank You to fjruple For This Useful Post:

-

Legacy Member

I'm gonna jump in with a touch of wishful thinking....

Could these barrel shortening and rechambered rifles be host to the infamous 3GM-K cartouche? That would be something!

-

Thank You to rcathey For This Useful Post:

-

Legacy Member

I dont know if I will make it back far enough but I'm seeing docs that seem to imply they had the same single heat treatment as the low number M1903s.

I've seen a few very coy docs that imply that. I'm just running out of time at the archives so I dont know if I will have time to dig into the 1920s.

-

-

Advisory Panel

Originally Posted by

cplstevennorton

I'm seeing docs that seem to imply they had the same single heat treatment as the low number M1903s.

Let us know if that's the case, still...we've not heard of any fracturing. Quite the opposite. They're touted for their strength.

-

Thank You to browningautorifle For This Useful Post:

PM

PM