-

Banned

Parashooter

I’m not really angry at you, but your timing arriving in this posting did not help matters, I’m on suspension at Gunboards for arguing this same subject matter and ireload2 decided to bring the argument here.

One of the problems in these forums is the moderators are not rabid bullethead reloaders and can’t tell the BS from the facts so they say “both posters statements have merit” trying to be politically correct. My problems is I spent the last 25 years at a military depot trying to get people to read the manuals as an Inspector.

I brought every Enfield manual I could find into the Enfield forums hoping to bring the forums “into the light” and we are still in the dark ages.

NOTE: All cases get shorter when you first fire them and thereafter start getting longer until they need trimmed due to brass flow.

I will post more later with some photos of older Remington .303 cases and newer .303 cases, methinks the bean counters got involved…………………..

And NO I’m not mad at you because YOU are a bullet head reloader who is NOT rabid.

-

06-05-2009 01:37 PM

# ADS

Friends and Sponsors

-

Legacy Member

When I responded to this board anyone was free to respond. That you chose to was your choice only. Instead of engaging in discussion all you can focus on is the 2 narrow straws that you have been grasping at all along.

1. All American made brass is junk......with no real back up

2. You can fix the problem by fire forming with an O ring - no test results offered.

When asked for results you have never responded, you never answered the questions.

I asked what O ring you use ... No answer

I asked if you have tested a case to destruction ....No answer

It is apparent that any discussion with you will always reach the same dead end. A lot of conspiracy theories and no test results.

So be it. End of discussion with EH. EH - If you are unable to respond in a positive manner to my posts in the future please do not respond at all.

-

-

Legacy Member

Originally Posted by

Edward Horton

Parashooter

I’m not really angry at you, but your timing arriving in this posting did not help matters, I’m on suspension at Gunboards for arguing this same subject matter and ireload2 decided to bring the argument here.

One of the problems in these forums is the moderators are not rabid bullethead reloaders and can’t tell the BS from the facts so they say “both posters statements have merit” trying to be politically correct. My problems is I spent the last 25 years at a military depot trying to get people to read the manuals as an Inspector.

I brought every Enfield manual I could find into the Enfield forums hoping to bring the forums “into the light” and we are still in the dark ages.

NOTE: All cases get shorter when you first fire them and thereafter start getting longer until they need trimmed due to brass flow.

I will post more later with some photos of older Remington .303 cases and newer .303 cases, methinks the bean counters got involved…………………..

And NO I’m not mad at you because YOU are a bullet head reloader who is NOT rabid.

It seems that EH tries to poison the water for me where ever he goes. Please leave your finger pointing references to me out of your posts. What ever happened to you at gunboards was in the making long before I showed up there.

I came here to continue the discussion with whom ever wanted to discuss it since there was an interesting similar thread here.

-

-

Advisory Panel

More measurements

A friend had a head separation with his No 4. He gave me the remains as a fine example and two other cases obviously on the verge of separation, having wisely decided to bin the whole batch (from S&B). Not having anticipated this effect, he had not checked the case length before firing.

Example 1. Case length 2.239"

Example 2. Case length 2.239"

Example 1. Shoulder position a/c the "9 para" method 2.670"

Example 2. Shoulder position a/c the "9 para" method 2.672"

In other words, the shoulder has moved forwards a whopping 0.074-76" compared with the "new" value of approx. 2.596 given in the previous posting.

The case lengths are beyond the minimum chamber length a/c the CIP data sheet (I do not have the SAAMI info).

Sorry to bang on about this guys, but evaluating Enfields with SAAMI or CIP gauges is obviously an academic exercise which is not going to solve practical shooting problems. I do believe Peter Laidler has said something about this in the past. Peter, if you are following this thread, perhaps you would care to comment?

has said something about this in the past. Peter, if you are following this thread, perhaps you would care to comment?

Patrick

-

-

Legacy Member

Originally Posted by

Parashooter

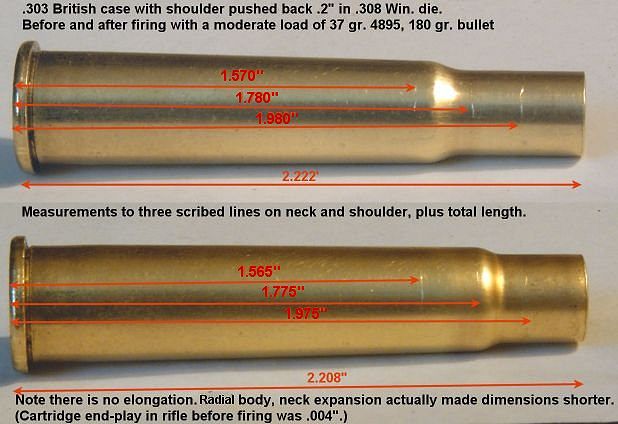

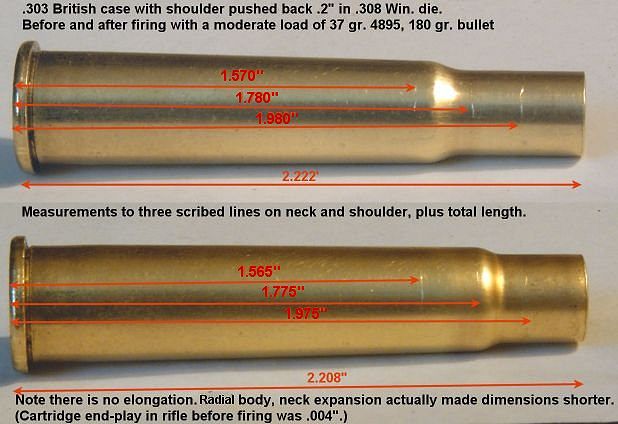

I have seen this idea with fair frequency and eventually decided to test it -

I believe that when a rimmed cartridge is fired with generous shoulder clearance the case expands outward to fill the chamber and there is little or no elongation (stretch) due to brass being "pushed forward". I'd be delighted to hear details of any tests that either confirm or refute what I've concluded from my little experiment.

-------------------------------------------------------------------------

Ed, I apologize for the offense. It was not my intent. I have great confidence in your measurements and observations about the .303 cases you've examined and shown us. That they differ from what I've experienced tells me there has been some significant variation in production - enough that I question the value of any generalization based on what either of us have observed in a variety of specimens.

To be specific, I question assertions that -

- US makers are routinely loading .303's to reduced pressure.

- Shoulder clearance is a defect in (new) rimmed cases.

- There is a qualitative difference in the metal US makers employ for .303 cases.

All of these may be valid points. I'm just saying that I haven't yet seen any conclusive evidence to support them and my experience differs. Please don't stay angry.

Para,

I have a similar observation. I have formed .303 brass from once fired .30-40 Krag brass. There is not really much to it other than trimming to length and resizing to retain a bullet. The Krag shoulder is far below the .303 shoulder.

brass. There is not really much to it other than trimming to length and resizing to retain a bullet. The Krag shoulder is far below the .303 shoulder.

It seems many hand loaders can only think of brass as stretching longitudinally.

What I have observed is that brass tends to stretch radially first then longitudinally. In the case of the Krag brass it had a different surface color at the shoulder than it did over the neck. When fired in the .303 chamber the case merely expand radially. A new shoulder is formed at the proper location in the .303 chamber. The color tone and previous sizing marks on the Krag shoulder remain where they were, they are just expanded in diameter.

Once fired Krag case on the left. Note color of shoulder.

The case on the right was trimed to .303 length and fired in .303 #4MK1.

Note color band on the should is still in the same location.

This from my Frankenstein box of .303 brass that includes reformed .444 Marlin, .30-40 Krag, WW Super, Western Super Speed, two different R-P headstamps and Herter's.

EDG

Last edited by ireload2; 06-05-2009 at 03:04 PM.

-

-

Advisory Panel

If only radial expansion, why separation?

For me, that is the No. 1 question. To understand how/why the head separation occurs, with the aim of doing something to avoid or at least reduce it.

Patrick

-

-

Two main factors, I think. Diameter of the case versus the chamber where the web thins out (probably of secondary importance) and case wall thickness. Granted there is some rearward displacment, but in the generously proportioned chamber a thin case will stretch and thin out near the juncture of the solid base. When sized, the displaced metal will not "rethicken" but will just displace forward. The distress is compounded w/ each firing and sizing cycle. Multiple factors at work here. Dang, even benchresters experience brass flow and other evilness(just takes longer).

-

-

Advisory Panel

Originally Posted by

Patrick Chadwick

. . . Have you got any explanation as to why the first scribed line (at 1.570") actually moved back towards the base? . . .

If the shoulder is just rolling forwards, without any stretching, surely one would expect the gap to expand between the first and second lines, and to contract between the second and third lines?

The first line moved back because the body of the case expanded. Since brass was "neither created nor destroyed" the increase in diameter resulted in a decrease in length. Here's an attempt to show this principle using a rubber band I took off a dead lobster -

Elastic cylinder (rubber band) loses length as diameter is stretched.

I think it's mistaken to assume that the case expands from rear to front, "rolling forward" as you say. Here are a couple of examples showing that the forward part of the case, being thinner-walled than the rear, actually expands first.

7.5 Swiss blanks made from .30/06 are very much undersized. Low pressure of blank charge blows out shoulder and front 1/3 of case.

blanks made from .30/06 are very much undersized. Low pressure of blank charge blows out shoulder and front 1/3 of case.

The .034" shoulder movement you describe sounds normal to me, just the usual "fireforming" action. One plausible way to explain the .019" total elongation is as an accumulation of clearances. For example, an .056" rim, .071" headspace (.015" end-play), plus .003" action flex, add up to .019". If you were to try the same test with the case or chamber lightly lubed, you might see less change in total length.

Upper case was neck-sized, loaded, and fired 10 times with 180-grain bullet, 41 grains RL15 (2450 fps). It elongated .002"-.003" at each firing, separated on the 10th shot, and was stuck so firmly that a normal "broken-shell extractor" wouldn't move it. (Pounding on chamber cast finally got it out.)

Lower case has been fired 15 times with same load but was lightly lubed with castor oil before each shot. There has been no elongation (and no wear on my SMLE that I can see or measure). When I get some more time, I'll increase the load to 42 grains (Alliant's maximum), see it I can get it to 30 or 50 shots and check again for any damage to the rifle. (Not recommending anyone else fire lubed cases in their Lee-Enfields - just trying to find out how it works in mine.)

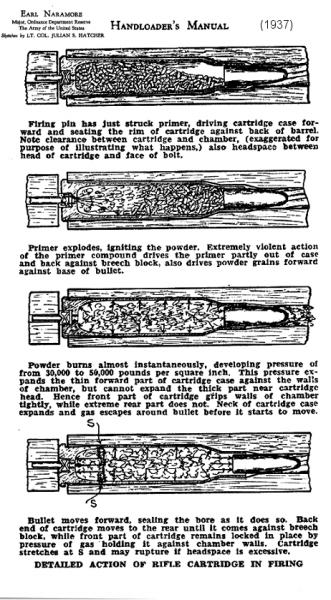

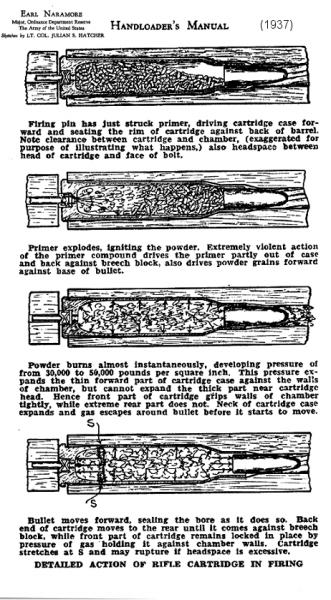

Here's the best illustrated explanation on the mechanics of head-separation I've found -

Notice that Naramore says the stretching occurs at the rear of the case (S) while the front is "locked in place".

This is my attempt at the same illustration, updated with color and motion -

Wish I'd called the initial space between case and bolt "end-play" instead of "Head clearance" but I'm too lazy to re-do the animation now.

-

The Following 4 Members Say Thank You to Parashooter For This Useful Post:

-

Advisory Panel

Thanks you for some very enlightening photos! And the animation convinces me that the answer is to make the head clearance as near to zero as you can. In other words - neck sizing only. Am I right, or am I missing something?

Patrick

-

-

Legacy Member

Para,

Not only is the brass thinner at the shoulder but it is also softer from annealing and therefore has a lower tensile strength than the work hardened brass near the head.

I have had the same results with hydraulic decapping of brass 7.62X39 berdan ammo. Using a water filled case I drove a 5/16 punch into the case and bulged the shoulder and front 25% of the case similar to your photos. Alas there were no digital cameras in those days.

-

Register To Reply

Register To Reply