-

Advisory Panel

Thanks for the weight and wall-thickness survey, Ed. So much for my raw mass theory!

As the specs you posted show, cartridge brass is a pretty simple alloy, around 70/30 copper/zinc with low levels of allowable impurities. It's a standardized product the ammo makers buy in huge rolls from the brass mills. If there's a difference in the quality of finished cases lately, I suspect much of it arises during their manufacture - whether from changing the number or rate of draw operations to speed production or maybe skipping some annealing (saving energy?) is certainly beyond my limited knowledge. No evidence, I'm just trying to apply a little logic to the question.

Fortunately (thanks to reduced loads and castor oil  ), I'm still using a few of the WRA-43 cases I first reloaded in 1958 and have many others that are "only" 20 or 30 years old. It's unlikely I'll ever need to buy more since "lifetime supply" is becoming a smaller quantity with each added candle on the birthday cake.

), I'm still using a few of the WRA-43 cases I first reloaded in 1958 and have many others that are "only" 20 or 30 years old. It's unlikely I'll ever need to buy more since "lifetime supply" is becoming a smaller quantity with each added candle on the birthday cake.

-

-

06-05-2009 09:29 PM

# ADS

Friends and Sponsors

-

Legacy Member

I have cases that are a different quality of brass from the 60s and 70s. they have been used in much higher pressure loadings than the parent 303 cases and are still sound.[303/22, 303/243, 303/25,303/270] That tells me it is not the chamber though case or shoulder splits did occur using current cases but no head separation. Using current cases in 303 head separation does occur sooner the brass looks different there may also be a difference in manufacture of the cases ie annealimg this is the unknown.

-

-

-

Legacy Member

Originally Posted by

Bindi2

I have cases that are a different quality of brass from the 60s and 70s. they have been used in much higher pressure loadings than the parent 303 cases and are still sound.[303/22, 303/243, 303/25,303/270] That tells me it is not the chamber though case or shoulder splits did occur using current cases but no head separation. Using current cases in 303 head separation does occur sooner the brass looks different there may also be a difference in manufacture of the cases ie annealimg this is the unknown.

But you have not covered the full conditions of use.

There is a high probability that your .303/XXX custom chambers were/are not as sloppy as the original Lee-Enfield chamber. You also did not mention what action was used on all the other variants. If an action other than a LE was used the data is not related to theis discussion. In addition without pressure test data your pressure estimate are speculation.

-

-

Legacy Member

The conversions were built on English and Australian No1 Mk3 and Mk3*, P14 actions. The 303s any thing that chambered 303 pre 1900 on. Head separation is a more recent happening. You are correct that i can not give a precise pressure figure. Speed in FPS were known as was hard bolt lift. Case capacity was measured and taken into account. Different case manufacturers were used and sorted to their best use in all of the above.

No1 Mk3 and Mk3*, P14 actions. The 303s any thing that chambered 303 pre 1900 on. Head separation is a more recent happening. You are correct that i can not give a precise pressure figure. Speed in FPS were known as was hard bolt lift. Case capacity was measured and taken into account. Different case manufacturers were used and sorted to their best use in all of the above.

-

-

At this point it looks like chemical analysis tests and crystalline photo analysis in the longitudinal and transverse sections of various new and old unfired cases would have to be made to prove anything. Anybody w/ resources?

-

-

FREE MEMBER

NO Posting or PM's Allowed

O-RINGS in CHAMBERS

A few years back I pointed out that if one is using brass with thin rims as in the US produced 303 brass one can take a thin o-ring and force it over the cartridge to the rear of the case at the front of the rim.

This does a few things ----

a) it take up all the slack and forces the cartridge back against the bolt face thereby reducing any bolt thrust to --just thrust--not a moving hammer to the bolt lug faces.

b) it also benifits us by centering the cartridge in the chamber and thus hopefully centering it in the bore increasing acuracy by starting the bullet through the neck and the start of the rifling.

If you use the o-ring method you will immediately notice two things --but do this in a No1 mK3------

A)

1)Fire a round with no o-ring--now take the cartridge and look at the primer and the firing pin indent--off center isn't it. (if you have normal oversized chambers like 99% have)

2) look at the cartridge at the front of the rim the cartridge will be bulged unequally as is normal in oversized chambers.

now---

b)

1) take a cartridge--install an o-ring over the cartridge --here you have to decide the size it is up to you--they stretch well so use trial and error in dry fitting-- now take that cartridge or a few, maybe with a two or so different o-ring sizes installed. Fire them and look at the firing pin indent it should be in the center or noticeably more centered.

2) the brass will show equal expansion equally around the cartridge--this is good for the brass as well as the hoped for accuracy.

Check it out on older Lee's it works and works well.

I posted this on the older CSP forums for the guys and gals firing the 303's. I hope it helps you all with the brass expansion--your bolt thrust(hammering) accuracy etc.

forums for the guys and gals firing the 303's. I hope it helps you all with the brass expansion--your bolt thrust(hammering) accuracy etc.

Have a great day.

Regards

Terry in Victoria

-

Banned

-

Advisory Panel

Thanks to all who have contributed to make this probably the most interesting thread I have seen in months.

At the moment, my state of knowledge may be summarized as:

"Longitudinal and radial elongation play a role in creating the stress line that is a prominent feature in the typical Enfield head separations."

"This effect may be exacerbated by using brass of an inappropriate quality and/or thickness for the task."

"Head separation also occurs when the case fits the chamber better, it just takes more firings."

BUT

"The stretch that leads to head separation can be considerably reduced (eliminated?) by a lightly lubricated case. Really light. But not squeaky clean."

Now on the "Reloaders Bench" forum there is a thread "Case head exits rifle" where Parashooter provided the following quite from Hatcher:

"If the bullet had been dipped in grease, this generally meant that the neck of the cartridge was greasy too. The space between the neck of the case and the neck of the chamber was filled with an incompressible substance, and the first moderate rise in pressure found it impossible to expand the neck and release the bullet. Thus the powder was strongly confined right at the beginning of its ignition, and accordingly the pressure rose disastrously."

Hardly daring to argue with such an authority, I have noted that there is a certain degree of doubt as to whether or not Hatcher was following the army "party line" in this respect. Certainly thousands of BPCR shooters would be puzzled to hear that greasing bullets damages your rifle, as our everyday experience is that greasing in some form is absolutely necessary. And we are firing loads for 1000 yard shooting that go up into the 3000 Joule range, so we are not talking cats-sneeze loads here.

OK, you say, but blackpowder is irrelevant. I disagree, but let's look at a nitro-fuelled example.

I recently acquired a Swiss G96/11 rifle that is the best "out of the rack" milsurp for accuracy that I have ever had. I bought a pack of the Swiss GP11 surplus ammo which is perfectly tuned to this rifle (no surprise) and was surprised to see that the cartridges not only have sealed primers, but a wax coating aroung the bullet/neck junction to seal the joint there as well.

G96/11 rifle that is the best "out of the rack" milsurp for accuracy that I have ever had. I bought a pack of the Swiss GP11 surplus ammo which is perfectly tuned to this rifle (no surprise) and was surprised to see that the cartridges not only have sealed primers, but a wax coating aroung the bullet/neck junction to seal the joint there as well.

Of course, following the conventional wisdom of Hatcher, I cleaned the stuff off before firing. I wondered if the Swiss did that too, as cleaning up a 470 round package is, quite frankly, a bore. So I asked an eminent Swiss shooter, and I have no reason to think he was pulling my leg.

" Of course you don't clean it off," he said, "because on ignition the wax is simply squeezed out between the neck and the chamber into the throat and goes down the barrel with the bullet, incidentally preventing gas cutting and conserving the barrel."

Any comment? Was Hatcher right and hundreds of thousands of Swiss have been doing it wrong for a century? Is the typical bore on a Swiss milsurp ruined by the wax? Those I have seen are, without exception, beautiful, in a world where dealers are not afraid of selling rifles with ruined bores as if they were rare antiques. Are the bolt lugs hammered to death? Not that I have heard.

You see lads, at the moment I am tending to the hypothesis that if we are stuck with some degree of stretching which will lead sooner or later to head separation, but this can be practically eliminated, or at least greatly reduced, by a touch of case lubrication, then this perfectly fits my idea of creative laziness in quite simply not carefully cleaning off all traces of case lube from my rounds, but just wiping them down with a paper towel when they have been formed.

Saves work and improves case life - sound to good to be true. Is it?

Patrick

-

-

Banned

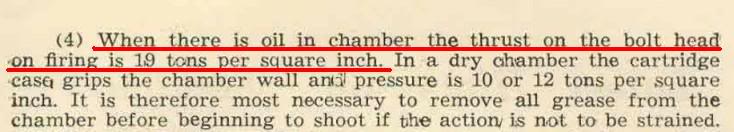

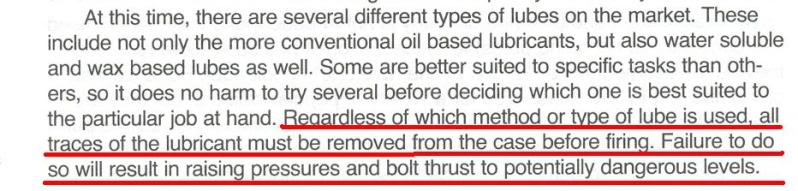

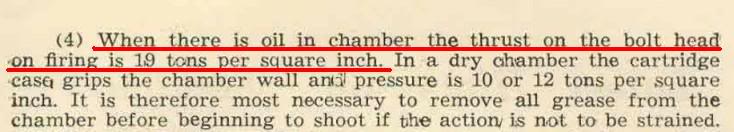

On the opposite side of the coin on oil and grease in the chamber, one was written in 1946 by Jim Sweet and the other is from a reloading manual.

The rubber o-ring method does not cause additional bolt thrust.

-

Legacy Member

It does not have to be one way or the other.

You don't have to chose between Mary Ann or Ginger.

In this case you can have both Mary Ann and Ginger.

The old wives tale about removing all traces of lube is of course never followed by the large majority of shooters. Most go to the range and start blasting with out wiping the oil that has drained in to their chamber after setting the rifle in the closet.

The Taisho 11th year is a light machine gun introduced in 1922, it remained in service until the end of World war 2. It has an unusual feed system consisting of a hopper mounted on the left side of the weapon. Five round charger strips are placed into the hopper and the gun strips out the rounds as they are fired, these chargers are the same as those issued to 6.5mm rifles, this was to allow any rifleman to supply ammunition to the machine gunner. This feed system turned out to be complicated and prone to stopages, in addition an integral oiler was included as the weapon required oiled cartridges for proper operation.

The Type 96 was introduced in 1936 to replace the Taisho 11. It is very similar but the hopper is replaced by a top mounted box magazine. The oiler was removed and the cartridges were oiled before loaded into the magazine.

The Schwarzlose Machine Gun M1907 was an extremely simple mechanism compared to other famous designs like Maxims. It was easy to make and proved reliable. The designer had managed to solve the problem with a delayed blowback system. The problem is that the breech starts moving backwards immediately as the cartridge is fired. The gas pressure is still very high and the walls of the cartridge case are expanded towards the chamber, which will cause very high friction. At the same time the extractor starts pulling out the empty cartridge case. The problem was solved by using very strong recoil springs and recoil parts together with a very short barrel. When the bullet left the barrel the pressure dropped while the kinetic energy of the recoil parts continued to pull out the empty cartridge case and reload the gun. The Schwarzlose machine gun has a device for oiling each cartridge to ease the reloading cycle. On each stroke oil was squirted into the firing chamber to lubricate the incoming cartridge case.

1912 some changes were made to the feed system and this change was called M1907/12. It had a straight top receiver and a simplified oil pad system instead of the pump mechanism.

As you can see some countries designed oilers into their machine guns to improve performance.

Polishing the chamber also improves case life as is mentioned on VarmintAls

In addition polishing your brass probably has much the same effect as oiling the cases. It reduces the effective coefficient of friction between the chamber and the cartridge case. It is also almost certain that an reasonable gun designer built in enough safety factor to a design to insure that oily ammo would not damage the action. An it is a fact that said designers know much more about the strength of an action that did some competitive shooter. Personally I am not going to let an obscure quote mined out of the back side of the internet over ride my personal judgment based on many years of successful reloading. In addition the .303 Lee-Enfield were given a larger chamber than originally designed just to accommodate dirt, mud and other battel field contamination. Certainly it was expected that both oil and water would be expected to get in some of these rifles in combat.

Last edited by ireload2; 06-06-2009 at 03:13 PM.

-

), I'm still using a few of the WRA-43 cases I first reloaded in 1958 and have many others that are "only" 20 or 30 years old. It's unlikely I'll ever need to buy more since "lifetime supply" is becoming a smaller quantity with each added candle on the birthday cake.

PM

PM