-

Legacy Member

Help With A Pitted M39 Barrel

Hello,

Picked up an antique M39 a few weeks ago. A 1941 VKT w/ an 1895 Tula receiver. The guy told me the barrel was good and so was the price. "Buyer Beware" When it came in I scrubbed the barrel before taking it to the range. A lot of crap initially came out of the barrel. Best group I got w/ my reloads was about 1 1/2". I've read that the Fins didn't let these rifles out of the arsenal unless they shot 1 1/2" w/ their ball ammo. So I figured w/ hand-loads, it should be a little better. I shimmed the receiver (like the Fins did), free floated the barrel and polished up the trigger. Took it out again, same results. continued to clean out the barrel and still having copper fouling coming out. I took the rifle to a local gunsmith to look at the crown and we determined to have the barrel re-crowned. Took it to the range again; same results. went back to see the gunsmith. He pulled out this gadget, it was a bore scope. Neat tool! he ran that tool through the bore and OH BOY!! you could see the pitting in the barrel. My heart sank. He told me there might be some hope. he said to pick up a cleaning rod, a can of Mothers Aluminum and Mag polish, and a few 30 cal mops. He told me to cut the handle of the cleaning rod and attach it to a drill motor. fasten a mop to the cleaning rod, and place some polish onto the mop. push the polish-soaked mop through the bore, fire up the drill motor and pass it back and forth for about 15-20 minutes. clean out the bore w/ solvent and patches and do it again. The mop will turn BLACK. He said not to worry. put some more polish on it and run it through again. It will slowly shine up the bore without taking off any metal. Well I did it for about 2 hours last night and it just now started to show signs of shining up. I won't be able to take the pitting out but it might help a bit. I'll put another couple of hours on it this evening.

Anyway, I was reading up this morning about fire-lapping using the Tubbs Kit/ method. They have a kit for .303 size bullets. The kit uses Sierra bullets. My hand-loads consist of Sierra 180gr SPT so I'm considering giving it a try. Has anybody had any experience with this system? How did it work out? Do you recommend it? Sorry about the long post. I wanted to give history. Thanks

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

-

02-08-2012 08:56 AM

# ADS

Friends and Sponsors

-

Legacy Member

Your fixin to ruin your barrel shore nuff. Never clean a bore( except possibly a rusty shotgun bore) using a drill motor or any circular motion. Think about it for a minute, you'll be polishing against the rifling. Besides, pits is pits and once there you cant get rid of them without excessive metal removal. At what distance is it shooting the 1 1/2'' groups? If 100 yds I'd think that was as good as it gets, after all these are battle rifles not target rifles. I've never used the Tubbs kit but I'd advise you to read up on the feedback about it first, lots of mixed results. I can't believe someone calling themselves a gunsmith told you to do this.

Last edited by vintage hunter; 02-08-2012 at 02:28 PM.

-

The Following 2 Members Say Thank You to vintage hunter For This Useful Post:

-

-

Contributing Member

A 1 1/2 inch group sounds like a very good group to me, especially if it is 100 yards with open sights. It also sounds like it meets Finnish specs now, not taking into consideration that it was probably heavily used after it left their arsenal.

specs now, not taking into consideration that it was probably heavily used after it left their arsenal.

Must second the opinion that the gunsmith isn't a very good one to advise you to clean the bore in that manner. To polish by it's very nature is the removal of something, to get a shine, you have to remove metal. As that cleaning rod gets further into the barrel, it is going to flex and rub on the interior and cause irregular wear.

-

Thank You to Aragorn243 For This Useful Post:

-

Advisory Panel

Just in case there is the slightest doubt remaining...

Originally Posted by

concretus

He told me to cut the handle of the cleaning rod and attach it to a drill motor. fasten a mop to the cleaning rod, and place some polish onto the mop. push the polish-soaked mop through the bore, fire up the drill motor and pass it back and forth for about 15-20 minutes. clean out the bore w/ solvent and patches and do it again.

The electric drill idea is the worst kind of Bubbary. This is NOT funny. I have seen several otherwise fine rifles that have been RUINED in this way.

As far as I am concerned, your local so-called gunsmith has totally disqualified himself.

Think about it. Basically, rifling is scratches ALONG the bore. Made in a controlled fashion, of course. Ringing is an enlargement ACROSS the bore, and ruins shooting qualities. Fire lapping does work, if you do it properly and don't try to cut corners. Small pits will tend to cause rapid "leading" (or should that be coppering?) but are actually less harmful to accuracy than rings caused by using an electric drill. Only ever use longitudinal motion that follows the rifling for cleaning barrels. NO CIRCULAR MOTION !!!!!

I don't fire borescopes (or headspace gauges) out of my rifles. I fire bullets, and the only real test is how those bullets perform. Borescopes (and headspace gauges) can be used to frighten shooters into an expensive or - in this case - potentially ruinous fix for a problem that may have other, better, solutions.

BTW, next time you have a problem, ask here first and, if necessary, find a different gunsmith.

Patrick

Last edited by Patrick Chadwick; 02-11-2012 at 06:15 AM.

-

-

Legacy Member

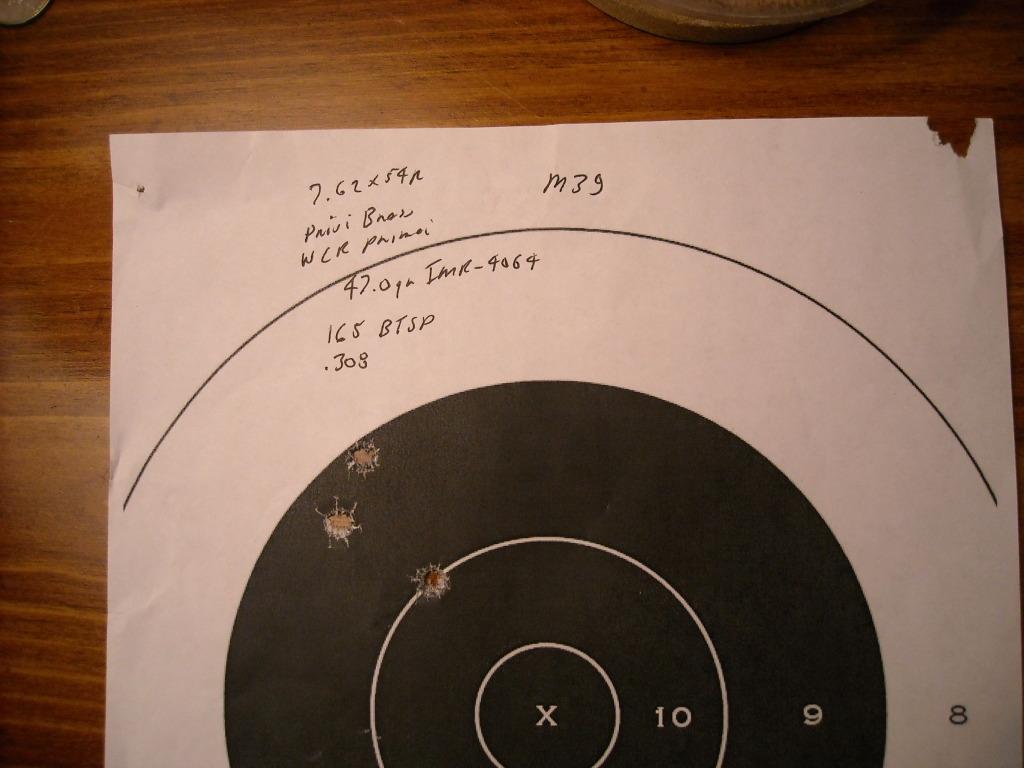

After the polishing w/ Mothers, finished up the cleaning with (two rounds of passes w. JB Bore paste, Hopes #9 until I got a clean patch and finally a patch w/ Kroil. The bore cleaned up nicely. Of course the "pits is pits" are still there but the rifling and the rest of the bore looked a lot better than before. I slugged the bore and got readings of .300-.301, and .309-.310; cleaned the rifle again to remove any lead residue. I worked up some loads using Sierra .308 165 BTSP GK and Sierra .311 180gr SPT PH. Took the M39 for a Spin on Saturday. Best groups were 1 5/16" and 1 1/4" respectfully. I'm going to try the .311 174 HPBT MK next and maybe the .308 175 HPBT MK Did the Fins just wrap the barrel at the muzzle or did they have some upward pressure?

-

-

Legacy Member

-

Thank You to concretus For This Useful Post:

-

Advisory Panel

Like I said...

Thank you concretus for the practical confirmation that pits need not be death to accuracy.

(But using an electric drill in the bore would have been!)

It looks like all you need to do with that rifle is shoot...clean ... shoot...clean...

B.T.W, a session with Neco 1200 grit bore-lapping paste (if it is still available) would remove any microscopic burring on the edges of the pits and thus slow down any copper fouling.

Patrick

Last edited by Patrick Chadwick; 02-16-2012 at 08:38 AM.

-

Thank You to Patrick Chadwick For This Useful Post:

-

Legacy Member

You are shooting .308 bullets, if I understand you. I would try .310/311/.312 bullets. There are many available, so do try them first before mopping out that bore.

-

-

Legacy Member

I've used both .308 and .311 bullets. With the .308 bullets, the powder choice made the difference. This past weekend I tried some Sierra .311 174 MK,s and bumped up the .308 bullet load 1/2gr of powder. the groups closed up another 1/4". Things are coming together. I have a broken box of Sierra .308 175 gr MK's I'm gonna see what they'll do. I guess I didn't sure nuff ruint that barrel.....

Last edited by concretus; 02-22-2012 at 02:58 PM.

-

-

Legacy Member

Even a blind hog finds an acorn every now and then.................................

-

PM

PM