-

FREE MEMBER

NO Posting or PM's Allowed

Bedding a S.M.L.E

Hi.

Can anyone give me info. on military bedding of the SMLE ? I have two and have had to replace the whole recoil lug area of one due to oil rotting and will be replacing the draws of the other and tightening it all up due to wood shrinkage. I know the action area bedding is similar to the No 4 but I can find no info anywhere on what happens forward of the knox form on the SMLE . My book "The Elements of Rifle Shooting" by Major Barlow, says that there should be free movement at the muzzle within the nosecap and that is easy to understand and the wood obviously must not touch the barrel forward of the knox form .It is the interaction between the inner band assembly and the fore end stud and spring that I don`t understand. Can anyone help?

Information

|

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current. |

|

-

07-01-2010 07:18 AM

# ADS

Friends and Sponsors

-

I believe Mr Edward Horton has a few a good references. If he doesn't have a reply for you shortly, search for posts under his name. Others, including Son, have most valuable info as well, but this is Ed's bread- reloading is his butter. ( Didn't mean to discourage anyone else from adding to the info, feel free to jump in!) There is a recent thread on a SMLE (No.1) target rifle that may also help, Let me see if I can find it...

ETA Here it is! Link below:

https://www.milsurps.com/showthread.php?t=22331

Last edited by jmoore; 07-01-2010 at 08:47 AM.

-

-

-

Banned

-

FREE MEMBER

NO Posting or PM's Allowed

[QUOTE=Smellysniper;126914]Hi.

Can anyone give me info. on military bedding of the SMLE ?

there's a lengthy photo article around here on 'the secrets of a fultons no1 mk3', that shows bedding examples. probably very useful.

-

Advisory Panel

For standard bedding you need a good firm fit between the front of the butt socket and the rear of the sear lugs, ensuring even pressure on both sides. Without this and the barrel sitting straight up the barrel channel you can go no further.

There should be contact on the top flat of the wood between these two points as well. The bottom surface of the magazine well ideally should contact the wood almost all the way around both sides, but at least for the front 3/4 of the way.

The receiver ring should bear down on the foreend all around the front trigger guard screw from about 5 o'clock to 7 o'clock, and the same for the barrel knox.

The barrel should contact the foreend for an inch before and after the inner band without the band screw fitted, and then again for at least four inches to the muzzle.

Without the inner band screw and nosecap fitted, the barrel should require between 4 and 6 pounds of upward force to lift it off the foreend at the muzzle.

When fitted tight, the inner band screw should just move against the spring when pushed up with a screwdriver, but should not have pulled the barrel down while tightening.

Here's a pic of a factory fitted foreend from a '55 FTR Lithgow that clearly shows it's contact marks. The barrel had contact for the entire length from the inner band recess.

that clearly shows it's contact marks. The barrel had contact for the entire length from the inner band recess.

-

The Following 5 Members Say Thank You to Son For This Useful Post:

-

FREE MEMBER

NO Posting or PM's Allowed

Many thanks to all for the info. I now understand nearly all what is required. The only thing I am unsure of now is the function of the forend stud and spring. If the barrel is touching the forend,as shown in the photo,when the nosecap goes on, the spring pressure will push it up until it is in contact with top of the nose cap hole. That means the barrel is then lifted away from the wood and free tp be moved down within the nose cap hole against the spring pressure. Is that right?

By the way ,I am not used to Forum Etiquette and if some of my actions on posting ,replies or the like are odd, it is just ignorance ! Also I will be unable to reply for a day as the computer is off for a while. Best Regards.

and if some of my actions on posting ,replies or the like are odd, it is just ignorance ! Also I will be unable to reply for a day as the computer is off for a while. Best Regards.

-

Advisory Panel

The nosecap seems to be a bit of a grey area. If the foreend has pressure from the barrel, the nosecap will compress the centering stud spring, trying to lift the barrel. Most rifles I have seen will have contact on the barrel from the front few inches of the handguard- also visible in the pic above. A lot seem to have the nosecap hole contacting the top of the barrel, but some the contact is held off by the installing of the handguard.

Bottm line... I think (and as usual my opinions are open for debate) that the barrel should be captive down onto the foreend by either the nosecap hole or the handguard. In your case I'd fit it, taking note of how it is fitting, and go and test the rifle for accuracy. If you aren't satisfied with the way it shoots, we can look further into it then.

The barrel centering stud and the inner band, from all the information I have seen, were only fitted to combat the effects on accuracy of a warping foreend. So a change in climate didn't necessarily mean every rifle had to be re-bedded.

-

Thank You to Son For This Useful Post:

-

FREE MEMBER

NO Posting or PM's Allowed

I think I have a plan of action now. I shall spend the next few days bedding and my next shoot is at Bisley on the 26th July at 200 yards. This particular SMLE is one that I have fitted with Aldis Mk. 2 scope using replica Purdey mounts and is as close as I can get to a genuine WW1 sniper. I have shot it a few times but zeroing is a bit of a pain due to the mount design and I felt it wasn`t grouping too well anyway.Hence my bedding inspection and discovery that not very much of the bedding is as it should be. I also have a 4(t) and can group to about 4" at 200 yds with that so a similar group with the SMLE would be nice. I feel most Huns would have been relatively safe with me behind the loopholes! I shall keep you posted. Thank you all again.

-

FREE MEMBER

NO Posting or PM's Allowed

There is no such thing as a dumb question so here is mine: What is a knox form?

-

Legacy Member

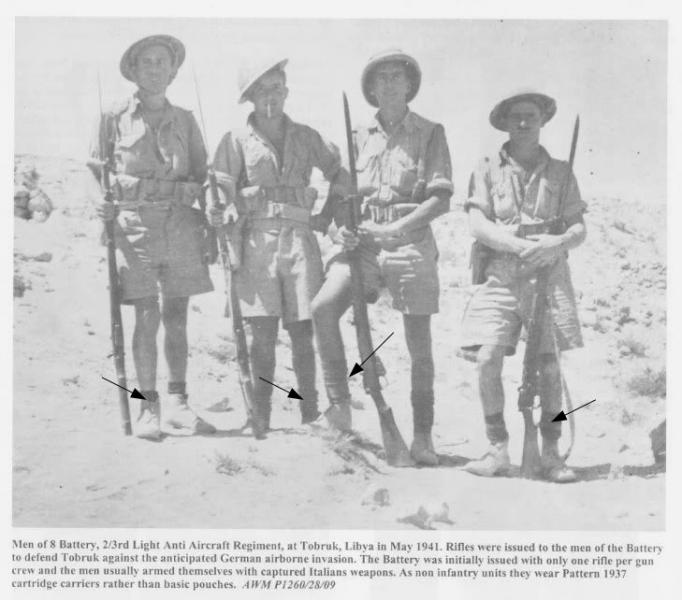

See the forward serial number, it is stamped on the knox form. The cone shape front end of the barrel that screws into the receiver.

Attachment 13920

"Self-realization. I was thinking of the immortal words of Socrates, who said, "... I drank what?"

-

Register To Reply

Register To Reply