-

Legacy Member

>>>Never trust anyone who can give you the “exact” figures on how much your bolt will compress and your action will flex.<<<

Design engineers use these same mathematical formulae to evaluate their designs before comitting them to metal for testing. Certainly my numbers are vastly more accurate than NO numbers.

These calculations are relatively simple and can be completed by anyone with simple math skills.

Deflection = (Force X Length) / (area X Young's modulus)

Force = PSI of chamber pressure X the internal surface area of the case head normal to the bore

area = the cross section area of the component under load.

Young's modulus = a known value for steel = 30,000,000

In the case of the LE action the bolt is compressed and the receiver is stretched by the chamber pressure.

Last edited by ireload2; 06-08-2009 at 02:00 PM.

-

-

06-08-2009 01:57 PM

# ADS

Friends and Sponsors

-

Advisory Panel

Originally Posted by

ireload2

Please show us the number that you base the 2% upon.

I guess I disagree with your conclusion. When the entire .010 difference in diameter is accommodated by localized stretching of a case the amount of stretching .010 is significant to the thickness of the brass - normally near .030 thick.

Let me use a couple of extreme example.

1. What is the usual result of firing a 7.62 Nato round in a .30-06.

You get a blown out .308 case with no neck. There is usually no separation reported even thos the .308 case had little real headspace control.

2. What happens when a .270 is fired in a 7mm magnum?

Usually the rifle is wrecked because the case could not handle the radial stretching.

These are extreme example of case missfits but they serve to show the critical nature of having the case head fit the chamber closely.

There is another example of case to chamber misfit that exists with the 6.5

Arisaka

. The Type 38 rifle is know to be very strong. It would exhibit very little spring with high pressure loads. After the first fire forming load it would have a fit from head to should to control the headspace. Yet ammo fired in these rifles give head separations due to the thinning of the brass where a huge step is formed due to the mismatch of the case head and the chamber.

OK, here's how I get that 2% thinning from .010" radial expansion in a .303 -- If the initial diameter of the case is .450", its circumference is .450"x pi = 1.413".

- If it expands to .460", the circumference is now .460 x pi = 1.445".

- The difference in circumference is 1.445" minus 1.413" = .032".

- .032 divided by 1.445 is .022 or 2.2%.

- The reduction in thickness of the case wall is directly proportional to the increase in circumference (To make this step easier for math-dummies like me to grasp, I imagine that we straighten out the radial section of the case into a thin rectangle 1.413" long and .030" thick. If we stretch it 2.2% longer, to 1.445", it must also become 2.2% thinner to maintain the same area. A simplified example is shown below.)

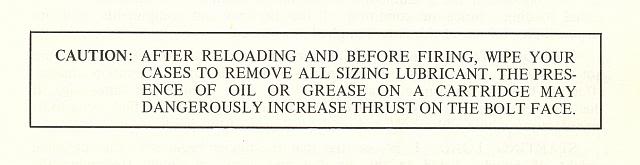

I've never had a problem with head separations in 6.5 Arisaka - but I habitually lube cases to reduce axial stretch. Same goes for 7.5 MAS and 6.5x55 formed from .30/06, where the parent case is about .015" to .020" undersize.

Because it has less body taper, 7.62 NATO chambered in a .30/06 chamber is normally a very tight fit at the shoulder, eliminating end play because the 7.62 is wedged firmly in place. If the chamber is oversize or the case undersize, the extractor holds the case close enough to the bolt face to keep axial stretch within limits - if it didn't, the firing pin couldn't reach the primer.

Look closely and you can see the scratches where the former shoulder was forced into the chamber.

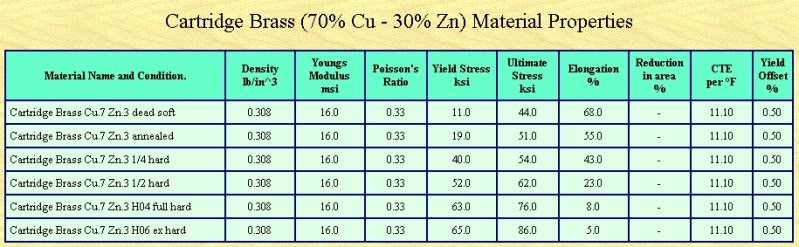

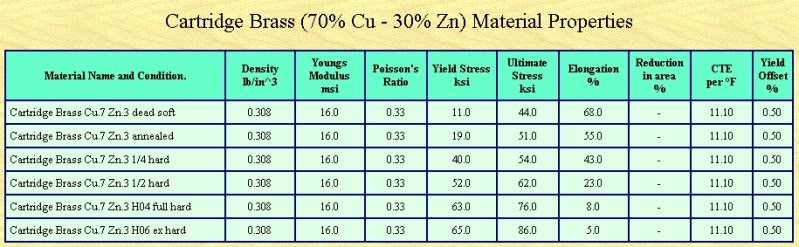

.270 Win. fired in 7mm Magnum has to expand from about .470" to .515", a 10% change in circumference. This can exceed the elastic limit of the brass case. (See http://www.engineershandbook.com/Tables/copperprop.htm and you'll find the elongation limit for cartridge brass in the "hard" condition we might expect in a case head is 8%. Or we could trust the table Ed provided earlier in this thread, with the same 8% elongation for "full hard".)

-

-

-

Legacy Member

My definition of radial stretching is a bit different than yours.

First of all you described what I agree would be circumferential thinning.

What I call radial thinning it the big step the case has to form on one side when it is off center in the chamber. From .450 to .460 creates a step of material .010 tall. If you looked at a fiber of that material it would have originally be aligned axially how ever when dispaced at right angles to the case axis I call it radial stretching. This material was once a straight case side wall. When fired, suddenly .010 extra length of material has be stretched from a short area of the case body.

Consider the material is only .030 thick or so you have large amount of stretch concentrated in a small spot. That area rapidly becomes the weakest area on the case because of the additive nature of the axial and radial thinning being concentrated at the step near the solid head.

A lot of my case ideas are only tests to determine if improved head to chamber wall fit will significantly increase case life. They are not mean't to be anything more than educational at this time. If they do improve the case life a little there are a few other things that might help a little.

If all the things work maybe case life in the LE can be made tolerable.

Today I amde some cases out of .405 Win. The head dia is .458 and my chamber is .460. The cases weigh 195 grains the heaviest .303 creations yes.

The rim thickness was not the .074 predicted by EH's Hornady Manual page.

The rims are only .066 thick on avg. If the reims are too thick I know a very fast way to thin them for be an exact thickness for a given rifle.

I set the shoulder tight and I will lightly lube the cases when they are fired.

They will be compared against .444 Marlin brass and a wide array of others including Interarmco, Herters's, Norma, WRA 1943, FC , R-P and WW.

I expect the Marlin and the .405 Hornady brass will be long lived. I have no idea what will happen to the rest.

-

-

Legacy Member

>>>>270 Win. fired in 7mm Magnum has to expand from about .470" to .515", a 10% change in circumference. This can exceed the elastic limit of the brass case. (See http://www.engineershandbook.com/Tables/copperprop.htm and you'll find the elongation limit for cartridge brass in the "hard" condition we might expect in a case head is 8%. Or we could trust the table Ed provided earlier in this thread, with the same 8% elongation for "full hard".)<<<

These split lengthwise down the side of the case. Since the case head is too small to form a good cup and seal the breach the gas escapes into the receiver of a BAR and blows out the magazine, swelling the receiver walls and partially splitting the for end.

-

-

Legacy Member

.405 brass being formed to .303

Finished .303 formed and trimmed from .405

http://i14.photobucket.com/albums/a3...05brassJPG.jpg

.303 formed from .405 loaded

This brass is .458 at the head for .002 clearance in the chamber.

The .303 brass formed from .405 weighs 195 grains.

http://i14.photobucket.com/albums/a3...5loadedJPG.jpg

-

-

FREE MEMBER

NO Posting or PM's Allowed

Originally Posted by

ireload2

>>>Never trust anyone who can give you the “exact” figures on how much your bolt will compress and your action will flex.<<<

Design engineers use these same mathematical formulae to evaluate their designs before comitting them to metal for testing. Certainly my numbers are vastly more accurate than NO numbers.

These calculations are relatively simple and can be completed by anyone with simple math skills.

Deflection = (Force X Length) / (area X Young's modulus)

Force = PSI of chamber pressure X the internal surface area of the case head normal to the bore

area = the cross section area of the component under load.

Young's modulus = a known value for steel = 30,000,000

In the case of the LE action the bolt is compressed and the receiver is stretched by the chamber pressure.

The reason they do the testing is because the math only gets them close, empirical testing gets them the rest of the way. In other words, the gun still don't work from the numbers and they still have to fiddle around with the thing to get it to work.

I did know one of the engineers at Stevens who'd convinced the government to allow the changes to the Thompson and Stevens so they could actually make some money on the low bid contracts. He said to me what I just repeated to you. I've confirmed it with other firearms engineers. The math only gets you so far.

And you are using math against a finished product. And a known value for steel that may not be the value for this steel.

Kinda like doing things bass ackwards.

Last edited by limazulu; 06-09-2009 at 11:44 PM.

-

Banned

-

Advisory Panel

Originally Posted by

ireload2

These split lengthwise down the side of the case. Since the case head is too small to form a good cup and seal the breach the gas escapes into the receiver of a BAR and blows out the magazine, swelling the receiver walls and partially splitting the for end.

Yes, and the reason is that the radial (circumferential) elongation of approximately 10% exceeds the elastic limit of the brass in that part of the case.

-

-

Legacy Member

Originally Posted by

limazulu

And you are using math against a finished product. And a known value for steel that may not be the value for this steel.

Kinda like doing things bass ackwards.

My statement clearly says that engineers use the numbers to evaluate their designs before committing them to steel for testing. My numbers are only used to predict the deflection of the metal under a load. Therefore it uses only Young's modulus for steel. If you will take the time to review Young's modulus for steel you will find it is basically the same all steels. You can also find the drop dead simple equation used to generate these numbers. The deflections are real. The Lee-Enfield action is not as rigis as many presume.

Note it is not a measure of ultimate strength just the deflection under load. There is nothing bass ackwards about this at all.

-

Thank You to ireload2 For This Useful Post:

-

Legacy Member

>>>Let’s see at least $45.00 for the .405 cases, then you have increased home owners insurance because Teddy Roosevelt is going to haunt you until you’re in the grave, time involved with multiple case forming steps, $60.00 for a neck turning tool and another $7.00 for a pilot (plus shipping) and a dump truck to haul the excess brass away.

Or you can fire form your cases with a .29 cent rubber o-ring and save all the man hours and $139.95 in miscellaneous expenses not counting all the oil and grease you need to fireform YOUR cases.<<<

1. The cases were donated to me by another forum member. So it = $00.00 cost to me

2. I already own 7 neck turning tools and have access to a 13" engine lathe.

I have over 10,000 hrs spent running various lathes so turning the cases was no extra cost. I turn cases for other rifles so no big deal.

3. No new pilot was required I just used a .308 benchrest pilot. Who do you know that has benchrest quality brass for their .303 ?

4. I predict that the tonnage of brass hauled away will be less with .405 brass compared to using brass with undersize case heads that comply with the British standards. One separated case is more waste than trimming 50 cases.

standards. One separated case is more waste than trimming 50 cases.

5. I would also be glad to try your O rings recommendations. However when I asked you for the O ring size that you use you ignored my request. You have also ignored repeated requests for case life data using your O rings.

Since it has not been supplied I assume it does not exist.

I have no beef with your O rings but they will never cure the effects of the designed in mis-match between the case head diameter and the chamber diameter. Use of the .405 brass will tell me how much difference that clearance makes. In addition the thicker rim of the .405 fits my rifle like it was made for it. It must be the ghost of TR watching over me.

Let's see, we chose between a little extra oil on the case or all that gas you burn going to the parts house to buy O rings that eventually wind up as landfill material.

Last edited by ireload2; 06-10-2009 at 01:01 AM.

-

PM

PM