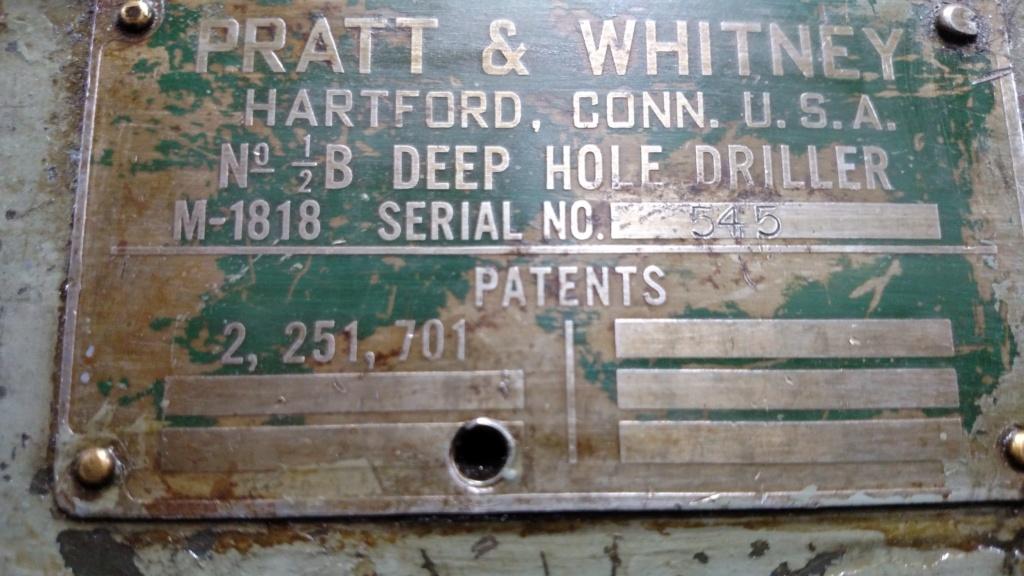

I just took a look at my 1950 Long Branch barrel with a bore scope. After spending most of last year trying to get the carcass of the former Montana Rifle Company up and running again, making barrels. The drills and reamers left behind by Remington/Montana Rifle company are 1930's Pratt & Whitney's, surplused from Springfield Armory, many of which still have the brass 'Springfield Armory' and 'Department Of War' brass tags on them. That's for context as I wonder what machinery and method Long Branch used in the 1940s/1950 to drill, ream, and rifle barrels.

Anyways, to the best of my knowledge, this Long Branch has never been issued, so it's total round count would be any rounds fired at the factory prior to getting coated for storage, followed by 20 rounds of Greek HXP by me, and then more recently five rounds of powder coated cast bullets, properly fitted to the leade/throat, and fired with 'the load'.

I did lead lap the barrel under the supervision of my gunsmith buddy who was building winning benchrest and fullbore rifles back in the 70's when I met him - when he wasn't placing and occasionally winning in those disciplines. So I couldn't have cocked up the lapping of the barrel too much if I did at all - the barrel felt wonderfully smooth when I was done; all the noticeable tight and loose spots when I started had disappeared.

So now with a borescope in my hands - and six months of looking down just completed barrel blanks - I looked at my Long Branch.

There's still reamer marks across the lands; they look like the surrounding steel has been polished and there's no sharp edges to the reamer marks, but they're still there. There what appear to be rough striations running at the bottom of the grooves; they look a little dulled rather than sharp. And there appears to be what appear to be small pits along this, with what almost looks like smoothed off very shallow gouges. Those small pits a legacy of a proof round that was then sealed in with the preservative applied afterwards?

And somewhat to my amazement, there was still an evident copper wash in places, polished to a very nice shine. Two patches of Sweet's, and the copper disappeared completely.

I'm not thinking my lead lapping was a dismal failure. I didn't have a borescope when I started to see the appearance of the bore at that point, nor to see the bore after the lap felt consistent from muzzle to throat. I'm surprised that the copper wash was still there, but I don't know how many microns (or whatever) thick was left in those spots.

What surprises me is the remaining striations and reamer marks after a day of lapping with successive grits of Clover compound. The reamer marks look as bad as the unmaintained and badly worn Pratt & Whitney's left behind as yet another bearing was packing it in. MRC button rifled; I never saw a button rifled barrel out of that plant that had striations in the bottoms of the grooves like my Long Branch. Not even remotely close.

Sooooo.... how did Long Branch do their rifling in 1950?Information

Warning: This is a relatively older thread

This discussion is older than 360 days. Some information contained in it may no longer be current.

- Knowledge Library

- MKL Entry of the Month

- Australia

- Austro-Hungarian Empire

- Canada

- Czechoslovakia

- Denmark

- Finland

- France/Belgium

- Germany

- Italy

- Japan

- Norway

- Russia

- South America

- Sweden

- Switzerland

- Turkey

- United Kingdom

- United States

- Yugoslavia

- Is my rifle authentic or a fake?

- Jay Currah's Lee Enfield Web Site

- On-line Service Records (Canada)

- Technical Articles/Research

- Forum

- Classifieds

- What's New?

-

Photo Gallery

- Photo Gallery Options

- Photo Gallery Home

- Search Photo Gallery List

-

Photo Gallery Search

- Video Club

- iTrader

PM

PM