-

Advisory Panel

Don't let it get to you, slamfire1. Your antagonist here appears not to want a rational discussion of this topic but intends to 'out-shout' anything that doesn't fit his position on the subject. It's sad because he's more interesting and has much to contribute when he puts down the megaphone, climbs off the soap-box, and shows his better nature.

Your posts about cartridge lubrication here and elsewhere have been very informative for me and I do appreciate them.

-

-

03-26-2010 11:46 PM

# ADS

Friends and Sponsors

-

Banned

The M16 /A4 has a polished chromed chamber, and the U.S. Military tells you to NOT oil or lube your ammo. The M16/A4 also doesn’t shoot Teflon coated ammunition it uses standard brass cartridge cases. When the brass cartridge is fired, the pressures inside the cartridge case rise to over 50,000 pounds per square inch. On ignition, the interior of the cartridge case is pressurized evenly, as the pressures increases the case walls expand and grip the sides of the chamber. The case stretches rearward until the base of the cartridge contacts the bolt face which supports it, putting pressure on the bolt.

/A4 has a polished chromed chamber, and the U.S. Military tells you to NOT oil or lube your ammo. The M16/A4 also doesn’t shoot Teflon coated ammunition it uses standard brass cartridge cases. When the brass cartridge is fired, the pressures inside the cartridge case rise to over 50,000 pounds per square inch. On ignition, the interior of the cartridge case is pressurized evenly, as the pressures increases the case walls expand and grip the sides of the chamber. The case stretches rearward until the base of the cartridge contacts the bolt face which supports it, putting pressure on the bolt.

An oiled or lubricated cartridge case does NOT grip the chamber walls and the bolt is exposed to twice the force that it would normally receive with a dry cartridge and this can and will damage any firearm.

Below is at least the third time I have quoted one of the sources you have listed in your postings above.

Below is from the source you listed in your last posting.

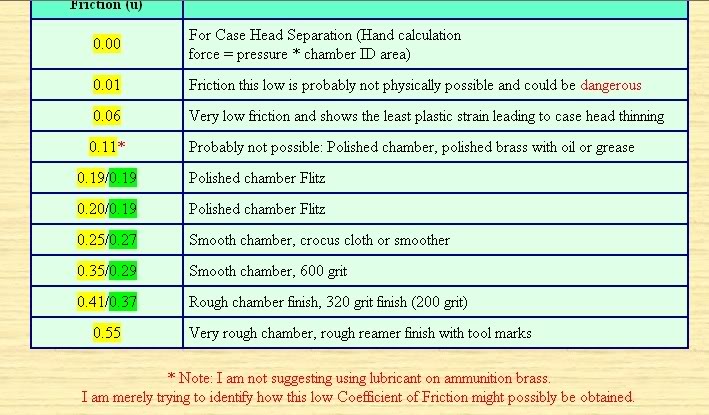

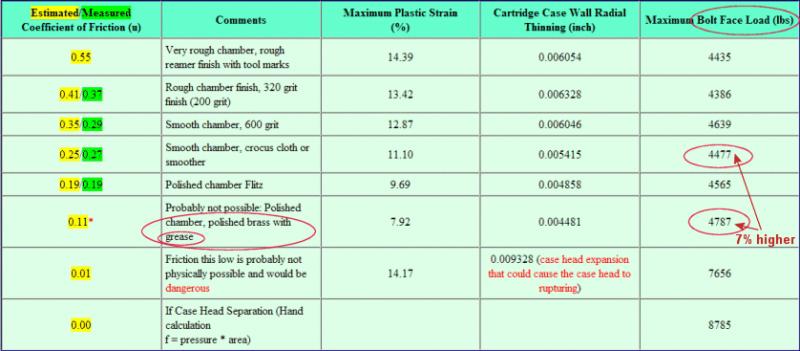

Rifle Chamber Finish & Friction Effects on Bolt Load and Case Head Thinning.

Please NOTE the author does NOT recommend lubricating the cartridge case.

I do not recommend that forum members disregard all safety warnings put out by the firearms manufactures, the Ammunition manufactures, the reloading companies and the U.S. military.

Last edited by Amatikulu; 03-27-2010 at 07:17 AM.

Reason: clarity

-

Stupidly enough, w/ a L-E design the surest way to good case life for reloading purposes IS to LUBE the cases w/ the slickest high pressure lubricant you can find. Since the action WILL flex, allowing the entire case to slide along in contact w/ the bolt head will prevent localized deformation.

Is it dangerously "hard" on the action? Not so far that any hard evidence can support to this point!

Are there potential dangerous consequences? Only if the endurance limit is lowered to the point that the action is not likely to required have a complete overhaul or retirement due to other wear factors.

"Fatigue" engineering wasn't really quantified until the Post WWII period, only reaching a fair level of maturity in the mid to late 1950's, I think. So, the Enfield designers had no way to put "hard" numbers to this aspect of design w/o actually physically testing actions to failure. That would have required MANY samples as the endurance limit can vary by a factor of ten pretty easily due to many factors.

Given that there are no known failures of this sort even after many years of service INCLUDING in 7.62x51 caliber, it is appearing to be a NON-ISSUE.

I've found a crappy No.4 barreled action that I'm thinking we'll rechamber to 300 Win Mag or maybe 300 WSM and shoot it off a test stand for a bit. Both dry and lubed. 0.308" and 0.311" bullets providing it holds up. Just gotta see if I can minimize the reamer cost. WBS2111 thought he had one, but no joy, or we would have done it yesterday.

Oh, BTW. somewhere there's a likely failure model that I postulated (w/ no evidence except bolt head failures, though) in another thread. Let's see if I can find it.

-

-

Here's some text of older musings:

"One rifle that seems to have an unusually low "fatigue life" is the FAL et al.

Seem to remember published failures being noted starting at roughly the 40-50,000 round limit. Life was doubled by changing the method of producing the raw receiver, but I 'll have to go back to Stephen's book and refresh memory.

M9 pistols suffered from a horribly low life limit, but it was discovered early in its life cycle, so changes were made. No such drama was associated w/ any of the Lee Enfield derivatives of which I'm aware.

ETA:

Another example. Early Glock 17 slides would fail through the ejection port RH side at around the 100,000 to 125,000 round mark, invariably cutting across the post finish (and hardening step) proof mark. Moving the proof raised the failure point to roughly 250,000 rounds.

The point here is that the load path, Although a bit more assymetrical than a No4, is similar in concept. The pistol would CONTINUE to function even w/ the RH side completely fractured, although POI tended to shift."

Another Post:

"More thinking whilst running the machine:

Probable failure order of a No4's structural components:

1.Bolt head-

A)first excessive overturn (common)

B) then, fracture at the thread terminus (No No4 examples on hand, but I've several SMLE bolt heads broken off at this point.) - New ETA- Change "thread" to "shank/external bolt head junction".

2.Bolt -

A) Forward face wear takes out most of these, I think.

B) Also the small lug in the striker cam area sometimes fractures- seen a few of those.

C) Bolt lug wear

D) Bolt lug shears off LH side - Never seen or heard of it though!

3.Receiver Body-

A)Bolt lugs wear through the hardened mating surfaces- Caught upon inspection- no real danger here.

B) Fatigue failure of RH receiver rail. Rifle contiues to function-sort of -probably begins to bind up on cycling and POI/accuracy go out the window.

C) LH receiver wall fails- a bad day! But there ought to be all the warning signs above.

Pure speculation, though. Tear this argument to shreds if y'all wish!"

Last edited by jmoore; 03-27-2010 at 08:38 AM.

-

-

Legacy Member

If you don't know enough not shoot lubbed cases by this time in your lives you need to quit this game.

Pura Vida

Last edited by MJ1; 03-28-2010 at 08:55 AM.

-

-

Banned

-

Dang, The older I get the less I "know"! Do I shoot w/ lubed cases? Not really, but neither do I wipe the chamber and ammo w/ degreasers in a surgical way either. I'm sure there's some contamination. I've also shot in driving rain, covered in mud or grit, in freezing and broiling conditions. I've got an L42a1 w/ an absolutely hideous throat from in service usage that still is otherwise quite servicable and accurate.

Where's the dramas w/ the L-E? Nobody seems to have examples...

-

-

FREE MEMBER

NO Posting or PM's Allowed

In 1974 I sent a .270 Remington 760 Gamemaster to a Remington repair facility for warranty work. I had bought a bad batch of Remington primers that were recalled and these primers ruptured and scored-etched the bolt face with high pressure gas.

After the Remington repair facility received my .270 I received a call from the repair facility shop manager. I was accused of shooting extremely high pressure reloads in my Remington pump and this had damaged my rifle. I told the manager my rifle was sent back for repairs due to defective primers sold by Remington and the manager said he knew this but I also had damaged the rifle from hot loads. I told the manager I was loading 52 to 53 grains of IMR4350 and this was will below any maximum load.

Then came my surprise, the manager then asked me if I was lubing my case when fire forming them and I answered “yes”. There was a long sighing exasperated pause at the manager’s end of the phone and then he said in no uncertain terms to NEVER lubricate another case ever again because it places to much force on the bolt and receiver

What did the shop manager see that lead him to the conclusion that you were shooting high pressure loads?

What parts did they replace?

-

Advisory Panel

Originally Posted by

Edward Horton

Below is at least the third time I have quoted one of the sources you have listed in your postings above.

Below is from the source you listed in your last posting.

Rifle Chamber Finish & Friction Effects on Bolt Load and Case Head Thinning.

Please NOTE the author does NOT recommend lubricating the cartridge case.

If we're going to quote somebody's work, the least we could do is grab a selection more enlightening for the current topic. -

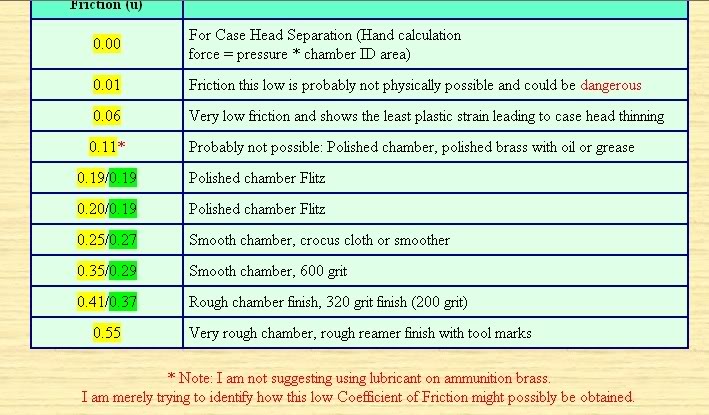

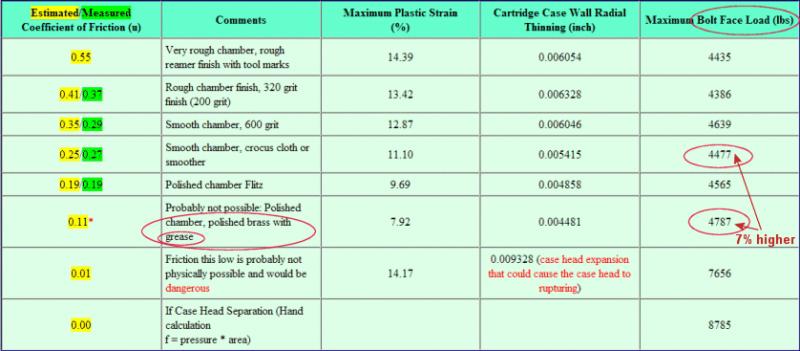

(The circles and arrows are not in the original, which can be seen at Friction Coefficient Tests of 416 Stainless Steel on Cartridge Brass .)

By now we all know that Mr. Horton and many others consider lubricated ammunition an extreme hazard - but let's be sure we're getting solid information to support that assertion. Simply citing authorities isn't enough for those of us who value original thought and practical testing. (Not too long ago, many authorities sincerely believed the Earth is flat. Didn't hold up to thorough investigation, did it?)

-

Thank You to Parashooter For This Useful Post:

-

Banned

The issue isn’t how many parts beside the bolt on my Remington 760 were replaced over 35 years ago.

The issue is the American firearms industry and the U.S. military tell you not to lubricate your ammo and yet people still come into our forums and tell us to ignore the safety warnings.

The U.S. military tells you to NOT lubricate your M16 -A4 ammunition because excess bolt thrust will damage the bolt, barrel and receiver.

-A4 ammunition because excess bolt thrust will damage the bolt, barrel and receiver.

The issue is you and the people who recommend lubing cases do NOT have the testing equipment or the experience the firearms industry or the military has in these matters.

The issue here in this forum if you are an American is you are dealing with a firearm considered an antique and curio that does not have to have the headspace checked or be re-proofed as they are in Britain or have ANY functional or safety checks done to the firearm before they are sold.

And then you want people to lube their cases when fire forming them or even lube the cases and fire them under normal pressure conditions.

The British to this day still proof pressure check their military firearms with lubed proof pressure test rounds to stress the action and to also simulate a over pressure conditions.

to this day still proof pressure check their military firearms with lubed proof pressure test rounds to stress the action and to also simulate a over pressure conditions.

And people still tell us its safe to ignore all the warnings…….. sorry but I’m going to keep telling people the other side of the story with published written facts.

Below an excerpt from a CMP online article.

online article.

When the "Tin Can" Changed History

By Dick Culver

While the 1920 NM Ammunition was accurate, it was still using a standard cupro-nickel jacketed bullet, although of the same 170 flat-based design as the 1921 projectile. The shooters of course, were solving the fouling problem with liberal applications of grease. Experiments at Springfield and Frankford disclosed that the 1920 NM Ammunition fired in a dry chamber gave approximately 51,000 psi, well within normal specifications. By carefully lubricating the bullet and case neck, the pressures rose to 59,000 psi. When the entire case was lubricated along with the chamber which was common (if unintended) when the cartridges were used in rapid-fire strings, the chamber pressure rose to a dangerous 71,000+ psi, the pressure normally attributed to a proof test load.

Physics and the Rifle Shooter

The inadvertently lubricated cartridge case was the worst problem as its sides were tapered. Normal ammunition forms a gas seal in the chamber due to a process known as obturation. Obturation is simply the expansion of the brass case, tightly sealing the chamber when the round is fired. This case expansion forces little fingers of brass to occupy unseen microscopic irregularities in the chamber walls. This is truly a good thing as it seals the chamber until the gas pressure has subsided. Unsealed chambers allow gas to blow back into the receiver, possibly injuring the shooter. The greasy cartridge case in a tapered chamber had two disastrous consequences. First, grease is incompressible and will not allow the case to expand

within the chamber as it was meant to do. Since the grease decreases the coefficient of friction and allows the cartridge case to slide in and out of the chamber more easily it precipitates what I call "the watermelon seed effect". This equates to the squeezing a fresh, wet watermelon seed between your fingers and having it squirt out into the grass. The greased, (and tapered) chamber has much the same effect on a brass cartridge case. Since the lack of compressibility of the grease prevents the case from expanding against the chamber walls and thus sealing the gas with normal obturation, the tapered case "squirts" to the rear with virtually all of the force of the combustion gasses being directed straight rearward against the bolt. When such rearward pressure is applied to the bolt in older single heat-treated receivers, exciting things are liable

to happen.

http://www.odcmp.org/1101/can.pdf

I told everyone before that the new Winchester Short Magnums (WSM) and Winchester Super Short Magnums were causing bolt thrust problems because the case does not have enough surface area to properly grip the chamber walls and rifle were being damaged from excess bolt thrust.

Now look at the latest Ruger Catalog and see if you see a single Ruger bolt action or single shot Number 1 chambered in any WSM or WSSM calibers.

Sturm, Ruger Co., Inc.

The people who advocate lubing cartridge cases are not doing their home work before giving out some very bad advice.

PM

PM